GaN-based laser with asymmetric Al component AlGaN limiting layers

A GaN-based, confinement layer technology, applied in lasers, laser parts, semiconductor lasers, etc., can solve problems such as severe, increased tensile stress, and warpage of GaN homogenous substrates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

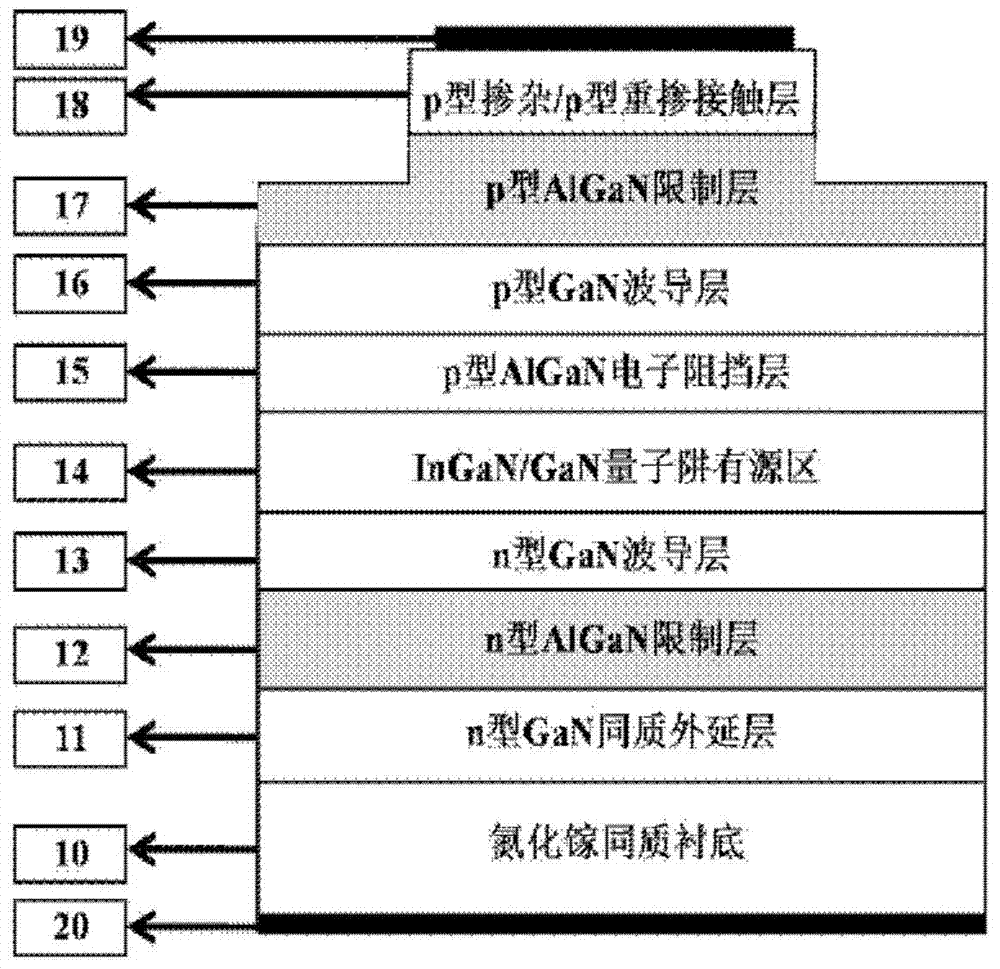

[0025] see figure 1 As shown, the present invention provides a gallium nitride-based laser with an asymmetric Al composition AlGaN confinement layer, comprising:

[0026] A gallium nitride homogeneous substrate 10, the gallium nitride homogeneous substrate 10 is an n-type doped self-supporting gallium nitride material with a thickness of 200-1000 μm;

[0027] An n-type GaN homoepitaxial layer 11, which is fabricated on a gallium nitride homogeneous substrate 10, the n-type GaN homoepitaxial layer is n-type GaN doped with Si, with a thickness of 1-10 μm;

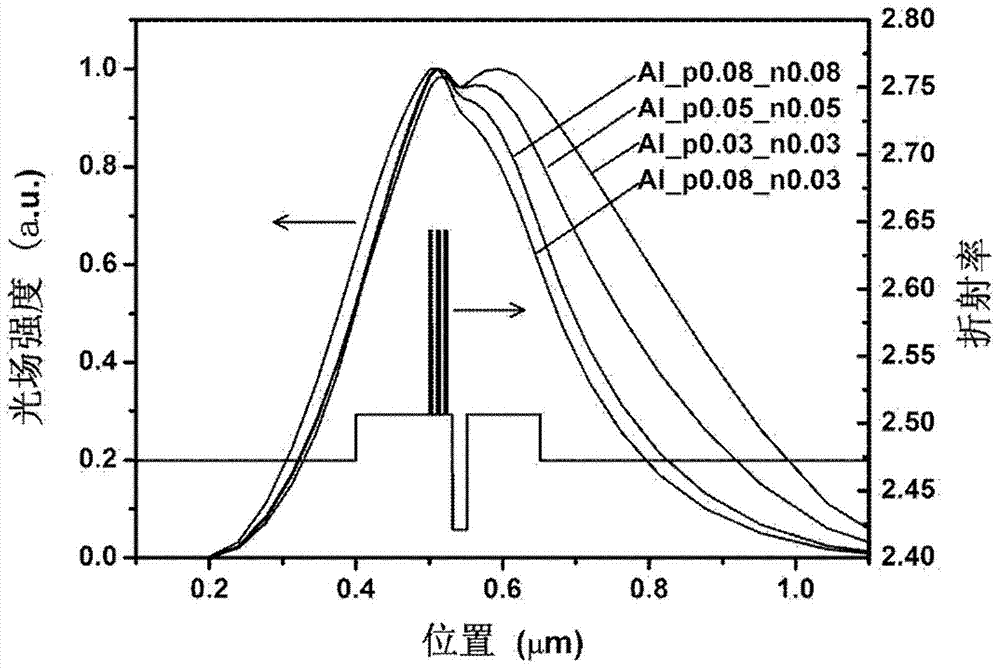

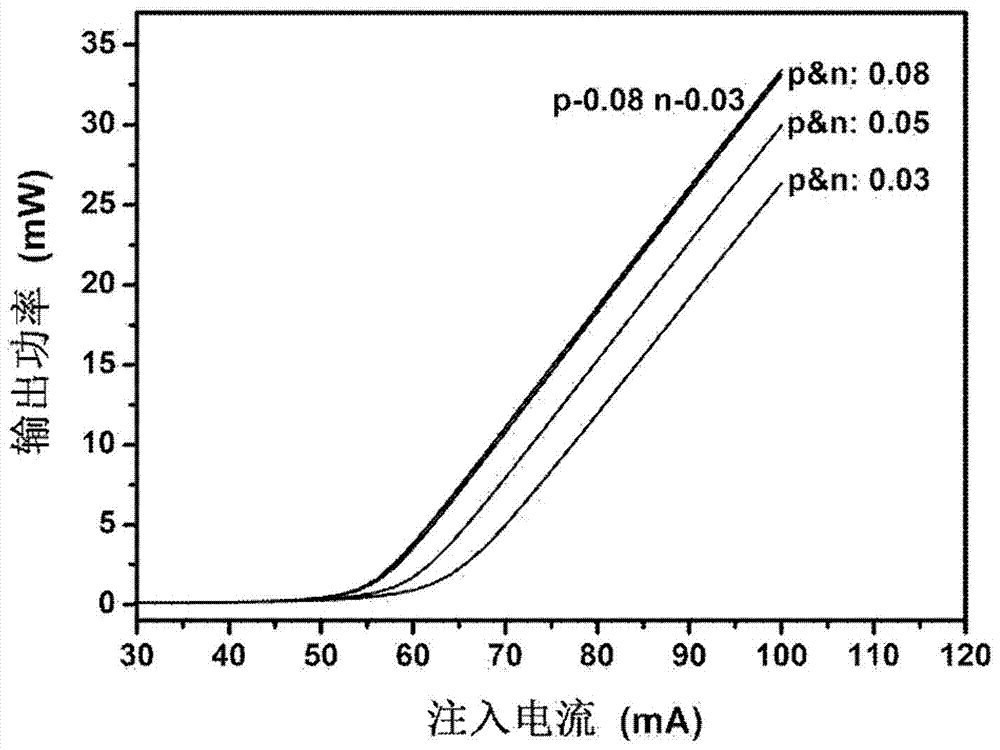

[0028] An n-type AlGaN confinement layer 12, which is fabricated on the n-type GaN homoepitaxial layer 11, the n-type AlGaN confinement layer 12 is Si-doped n-type AlGaN, the Al composition is 0.01-0.1, and the thickness is 0.2-1 μm ;

[0029] An n-type GaN waveguide layer 13, which is fabricated on the n-type AlGaN confinement layer 12, the n-type GaN waveguide layer is Si-doped n-type GaN with a thickness of 50-300 μm;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com