A combined drying and setting powder dot coating machine

A powder spot coating, drying and setting technology, applied in the direction of clothing, textiles, papermaking, textile materials, etc., can solve the problems of the interlining cannot be produced smoothly, affect the quality of the interlining, cannot guarantee synchronization, etc., and achieves simple structure, The effect of high precision and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

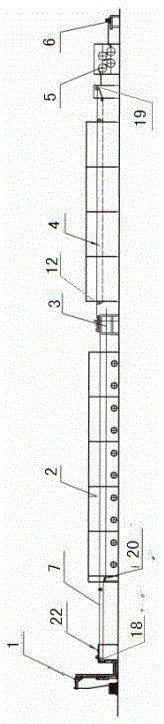

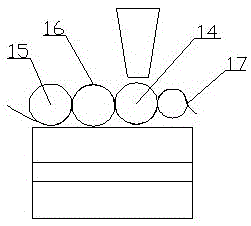

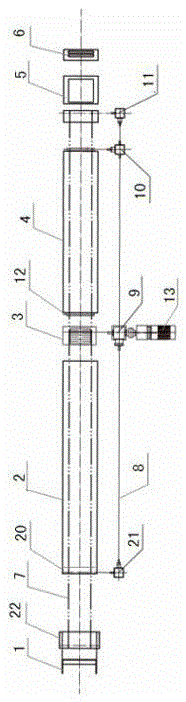

[0022] Such as figure 1 with figure 2 As shown, the present invention discloses a combined drying and shaping powder dot coating machine, which includes a cloth rack 1 for the unwinding station, an oven 2 for the drying and shaping station, and a powder dot coating station that are sequentially arranged. The powder point machine 3, the electric heating oven 4 of the sintering station, the cooling roller 5 of the cooling station and the coiling device 6 of the winding station, the gray cloth is sequentially transported to each station by a needle plate guide rail 7 extending along the direction of the station The station, each station and the needle plate guide rail 7 are synchronized by a main shaft mechanical transmission mechanism; the main shaft mechanical transmission mechanism includes an input shaft 8 extending along the direction of the station, and the input shaft 8 is connected by several input support shafts. And rotate synchronously through three output gear boxes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com