Fat emulsion injection and preparation method thereof

A technology for injection and fat emulsion, which is applied in the field of fat emulsion injection and its preparation, can solve the problems of poor emulsion stability and achieve the effects of improving stability, reducing adverse reactions, and increasing uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

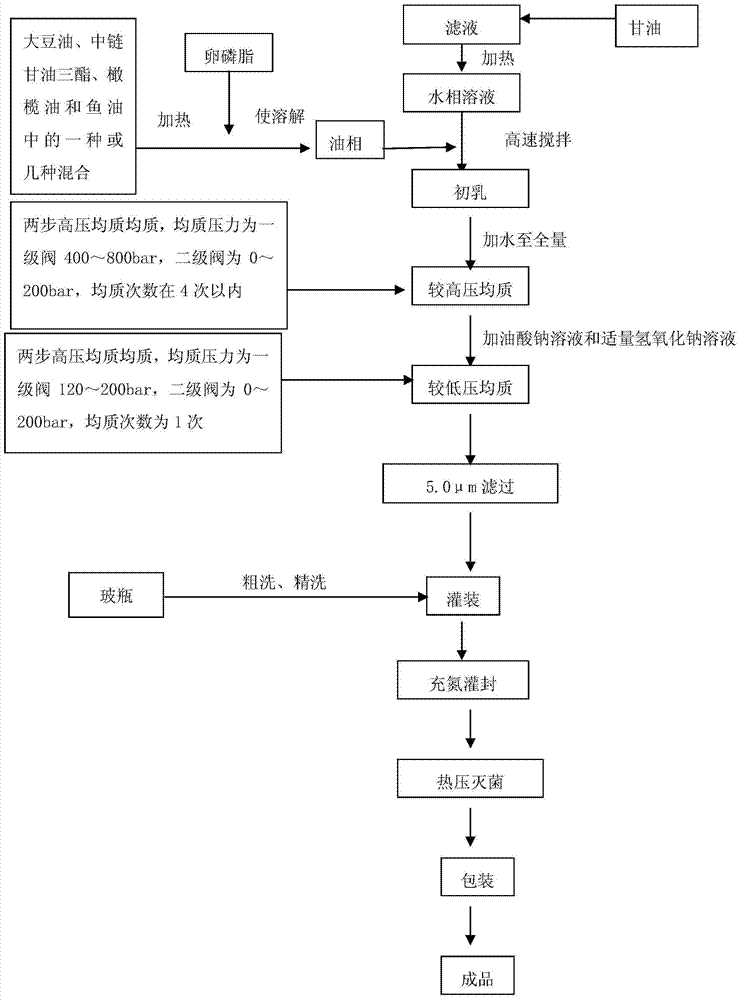

[0046] Example 1 Preparation of fat emulsion injection of the present invention

[0047] Oil phase preparation: take one or more of soybean oil, olive oil, medium-chain triglycerides and fish oil, heat to 60~85℃, add lecithin, stir and disperse to obtain; water phase preparation: add glycerin In a proper amount of water for injection, stir to dissolve and heat to 60~85℃ to obtain; mix the oil phase and water phase and add the water for injection to the prepared amount. After a two-step high-pressure homogenizer complete the higher pressure homogenization step, the homogenization pressure The first-stage valve is 400-800bar, the second-stage valve is 0-200bar, the number of homogenization is less than 4 times, the homogenization temperature is 50-65℃, add sodium oleate solution and proper amount of sodium hydroxide solution, and use after mixing. The two-step high-pressure homogenizer completes the lower pressure homogenization step, homogenizing once, the homogenizing pressure is...

Embodiment 2

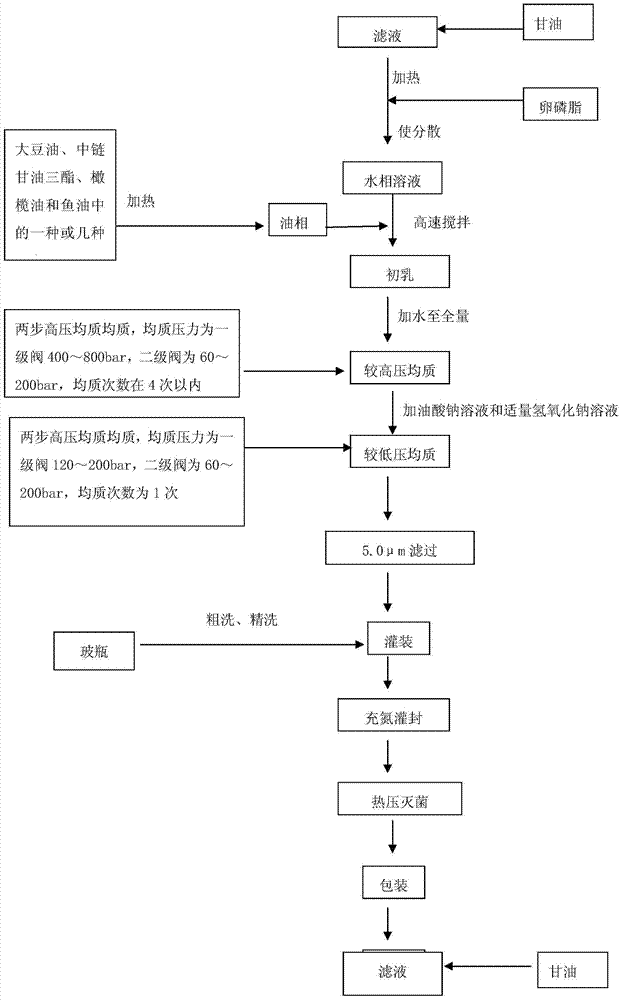

[0048] Example 2 Preparation of fat emulsion injection of the present invention

[0049] Oil phase preparation: take one or more of soybean oil, olive oil, medium-chain triglycerides and fish oil, and heat to 60~85℃ to obtain; water phase preparation: add glycerin to water for injection, stir to dissolve Then heat to 60~85℃, add lecithin, stir and disperse to obtain; mix the oil phase and the water phase, add water for injection to the preparation amount, complete the higher pressure homogenization step through a two-step high-pressure homogenizer, homogenize The pressure is 400-800bar for the primary valve, 0-200bar for the secondary valve, the number of homogenization is less than 4, the homogenization temperature is 50-65℃, add sodium oleate solution and appropriate amount of sodium hydroxide solution, and mix well. Use a two-step high-pressure homogenizer to complete the higher-pressure homogenization step, homogenize once, the homogenization pressure is 120-200bar for the fi...

Embodiment 3

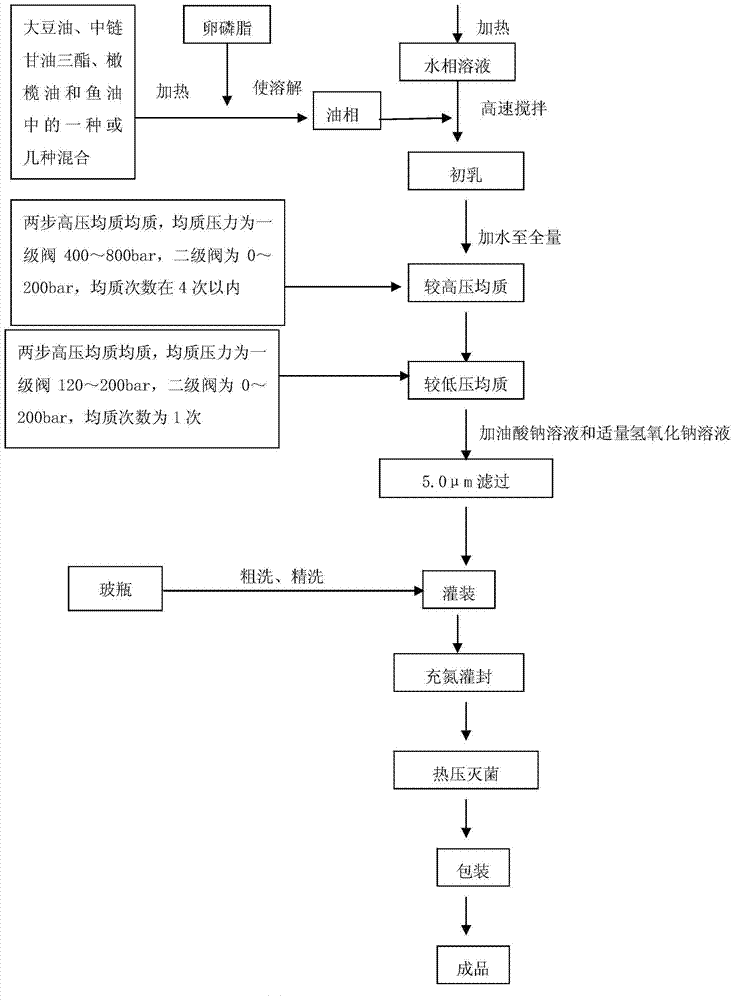

[0050] Example 3 Preparation of fat emulsion injection of the present invention

[0051] Oil phase preparation: take one or more of soybean oil, olive oil, medium-chain triglycerides and fish oil, heat to 60~85℃, add lecithin, stir and disperse to obtain; water phase preparation: add glycerin Mix the oil phase and the water phase and add the water for injection to the prepared amount after mixing and dissolving in an appropriate amount of water for injection. After a two-step high-pressure homogenizer, the homogenization pressure is 400~ 800bar, the secondary valve is 0~200bar, the homogenization frequency is 2~4 times, the homogenization temperature is 50~65℃, and the homogenization pressure is adjusted to 120~200bar for the primary valve and 0~200bar for the secondary valve. 1 time. Add sodium oleate solution and an appropriate amount of sodium hydroxide solution, stir well, fill the emulsion into an infusion bottle / bag, fill with nitrogen, stopper, press the lid, and keep it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com