Pipeline all-position laser and arc combined welding system

A laser arc and welding system technology, applied in laser welding equipment, welding equipment, tubular objects, etc., can solve the problems of contamination of laser welding torch focusing protection lens, welding slag splash, welding quality decline and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

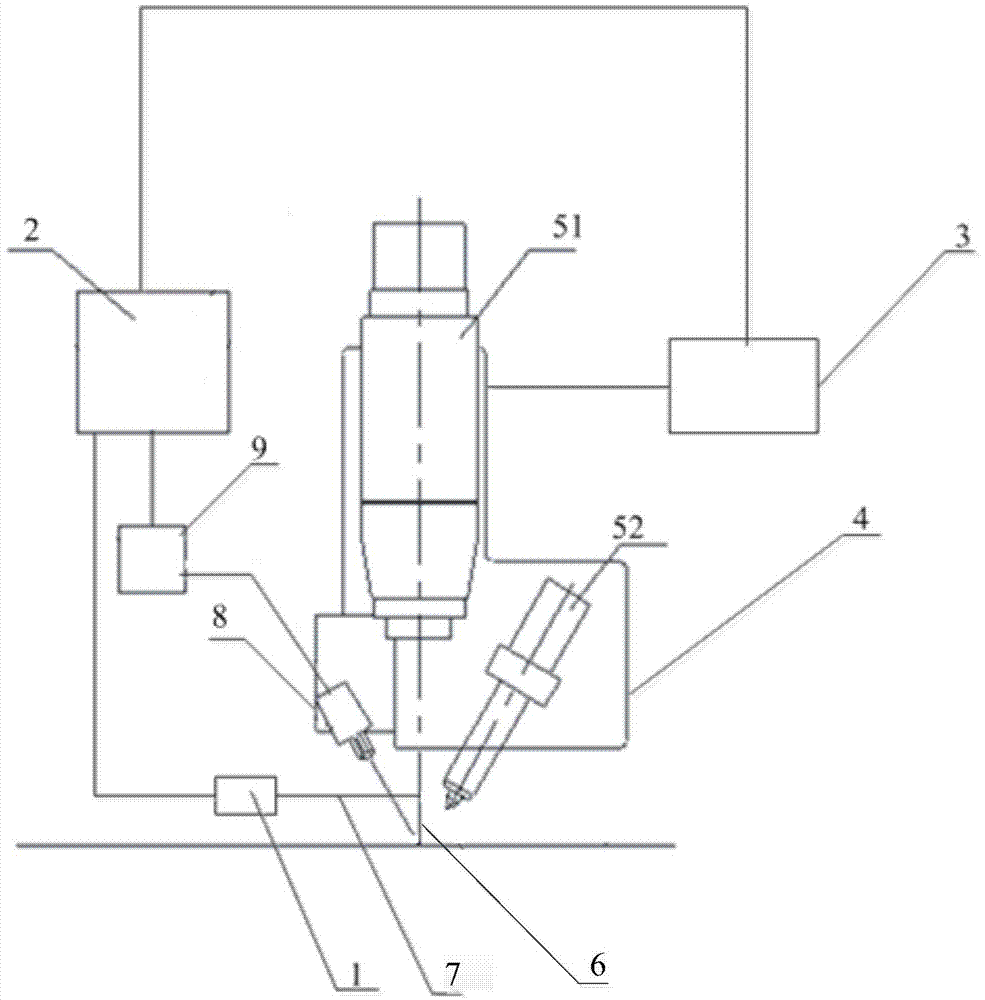

[0030] In order to solve the technical problem of laser arc hybrid welding welding slag splashing during the welding process, contaminating the focus protection lens of the laser welding torch, and resulting in a decline in welding quality, the invention provides a pipeline all-position laser arc hybrid welding welding system, which is characterized in that , the system includes: a laser sensor, the laser sensor collects the first position image information and the second position image information of the weld seam; an image processing computer, the image processing computer is used for according to the first position image information and the The second position image information calculates the lateral deviation and longitudinal deviation of the weld seam; converts the lateral deviation into a lateral deviation voltage, converts the longitudinal deviation into a longitudinal deviation voltage, and performs a delay according to the advance delay amount After calculation, send t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com