Preparation method of soil heavy metal curing detoxicant

A technology for heavy metals and antidote, applied in the field of environment and resources, can solve problems such as unfavorable soil compaction, mineral substance entry, and unfavorable soil ecological environment improvement, and achieve the effect of easy capture and increased surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

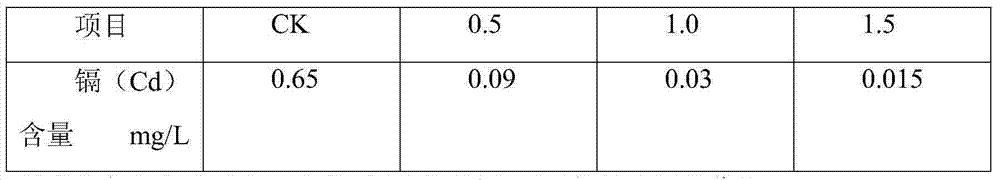

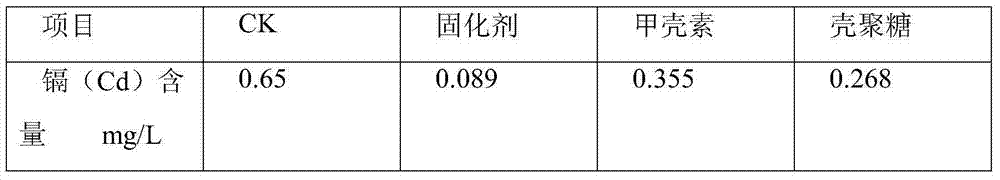

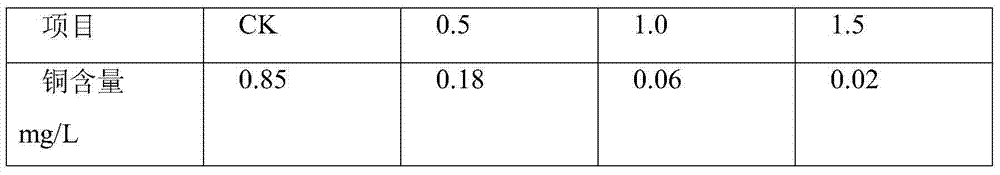

Examples

Embodiment 1

[0025] This example involves the use of medical chitin (produced by Zhejiang Jinke Biochemical Co., Ltd.) as a raw material for the production of soil heavy metal solidification antidotes. The chitin is pulverized to 200 mesh with a ball mill, and the weight ratio of part of the dissolving agent to the pulverized chitin is 100. 20, with a total weight of 14 kg, put it into a 10-liter reactor, dissolve at 95°C for 1 hour, adjust the pH value to 5.0 with neutralizing solution, add chitin and acylation preparation at a ratio of 100:0.01, and stir at 30°C Acylation reaction at low temperature for 6 hours, after that, add glutaraldehyde according to the ratio of chitin and cross-linking agent 100:0.1, stir at 50°C for 3 hours for cross-linking reaction, finish the reaction, dry, crush to 150 mesh, pack .

Embodiment 2

[0027] This embodiment involves the use of agricultural chitin (produced by Dalianguanfa Pharmaceutical Co., Ltd.) as a raw material for the production of soil heavy metal solidification antidotes. The difference between agricultural chitin and medical chitin is that agricultural chitin contains 10-15% of other organic matter, and the cost ratio Medical chitin is low. Use a ball mill to crush the raw material to 50 mesh. According to the weight ratio of part of the dissolving agent to the crushed chitin, the weight ratio is 100 to 10, and the total weight is 12 kg. Adjust the pH value of the neutralizing solution to 5.0, add it according to the ratio of chitin and acylation agent 100:0.05, carry out the acylation reaction under stirring at 85°C for 3 hours, and then add it according to the ratio of chitin and crosslinking agent 100:0.5 Glutaraldehyde was stirred at 30°C for 3 hours for cross-linking reaction, and the reaction was completed. After drying, it was crushed to 80 me...

Embodiment 3

[0029] This embodiment relates to the production of soil heavy metal solidification antidotes in a 50-liter reactor. The raw materials are pulverized to 100 mesh with a ball mill. The weight ratio of part of the dissolving agent to the pulverized chitin is 100 to 15, and the total weight is 23 kilograms. Add 50 liters of reaction In the kettle, dissolve at 75°C for 1 hour, adjust the pH value to 5.0 with a neutralizing solution, add chitin to the acylation agent at a ratio of 100:0.03, carry out the acylation reaction at 60°C for 3 hours under stirring conditions, and then press the chitin Glutaraldehyde was added to the ratio of 100:0.4 of the element and the cross-linking agent, and the cross-linking reaction was carried out at 45 ° C for 2 hours, and the reaction was completed. After drying, it was crushed to 120 mesh and packaged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com