Polyacrylate adhesive containing traditional Chinese medicine oil microcapsule as well as preparation method and application

A technology of polyacrylate and polyacrylate emulsion, which is applied in the field of polyacrylate adhesive and antibacterial textile preparation, and achieves good dispersion performance and good compatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

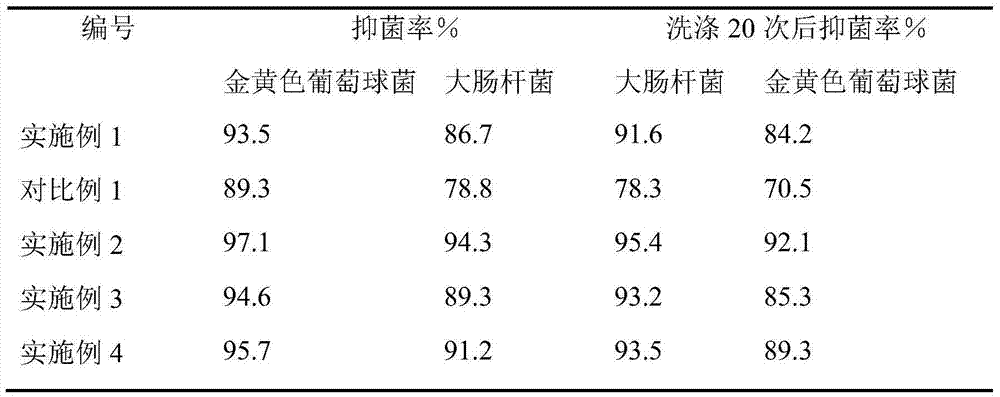

Examples

Embodiment 1

[0028] (1) Add 40mL of deionized water and 3.0g of cetyltrimethylammonium bromide into a four-neck flask, stir and dissolve, then add 2.0g of mugwort oil, at a stirring speed of 1500r / min, 40°C, Emulsified for 2 hours to obtain mugwort oil emulsion.

[0029] (2) Add 5.0 g of acrylic acid dropwise to the above-mentioned mugwort oil emulsion, stir mechanically for 10 min, and stir at a speed of 300 r / min, then add 5.0 mL of ammonium persulfate aqueous solution with a mass fraction of 1.0% dropwise at 75° C. under stirring conditions, Control the dropping rate, and finish dropping within 5 minutes. After the dropping, raise the temperature to 85° C. and keep warm for 15 minutes to obtain mugwort oil microcapsule emulsion.

[0030] (3) Dissolve 1.5 g of glycidyl acrylate in 10 mL of deionized water to make a functional monomer solution; dissolve 0.15 g of ammonium persulfate in 10 mL of deionized water to make an initiator solution.

[0031] (4) Dissolve 0.3g of sodium lauryl sul...

Embodiment 2

[0040] (1) Add 60mL of deionized water and 5.0g of octadecyltrimethylammonium bromide into a four-neck flask, stir to dissolve, add 5.0g of clove oil, and emulsify at a stirring speed of 3000r / min and 60°C 1h was clove oil emulsion.

[0041] (2) Add 8.0 g of methacrylic acid dropwise to the above-mentioned clove oil emulsion, stir mechanically for 15 min, and the stirring speed is 500 r / min, then add 5.0 mL of 1.5% sodium persulfate aqueous solution dropwise at 80°C under stirring conditions , control the dropping speed, finish dropping within 10 minutes, after the dropping, raise the temperature to 90° C. and keep warm for 10 minutes to obtain clove oil microcapsule emulsion.

[0042] (3) Dissolve 3.0 g of glycidyl methacrylate in 15 mL of deionized water to make a functional monomer solution; dissolve 0.30 g of sodium persulfate in 15 mL of deionized water to make an initiator solution.

[0043] (4) After dissolving 0.5g sodium lauryl sulfate and 1.5g Pingpingjia O-25 with ...

Embodiment 3

[0047] (1) Add 50mL of deionized water and 4.0g of dioctadecyldimethylammonium bromide into a four-neck flask, stir and dissolve, then add 3.0g of peppermint oil, at a stirring speed of 2000r / min, 50°C, Emulsified for 1.5h to obtain a peppermint oil emulsion.

[0048] (2) Add 6.0g of acrylic acid dropwise to the above-mentioned peppermint oil emulsion, mechanically stir for 12min, and stir at a speed of 400r / min, then add 5.0mL of potassium persulfate aqueous solution with a mass fraction of 1.2% dropwise at 78°C under stirring conditions, and control The dropping rate was finished within 8 minutes. After the dropping, the temperature was raised to 88° C. and kept for 12 minutes to obtain peppermint oil microcapsule emulsion.

[0049] (3) Dissolve 2.0 g of glycidyl acrylate in 12 mL of deionized water to make a functional monomer solution; dissolve 0.20 g of potassium persulfate in 12 mL of deionized water to make an initiator solution.

[0050] (4) After dissolving 0.4g sodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com