Launch canister demolding power device

A technology of power device and launch tube, which is applied in the direction of fluid pressure actuator, fluid pressure actuator system components, servo motor, etc. It can solve the problems of high weight-to-power ratio, unstable demoulding power, and large start-stop impact. Achieve the effects of reducing reactive power consumption, adjustable demoulding power, and small start-stop impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

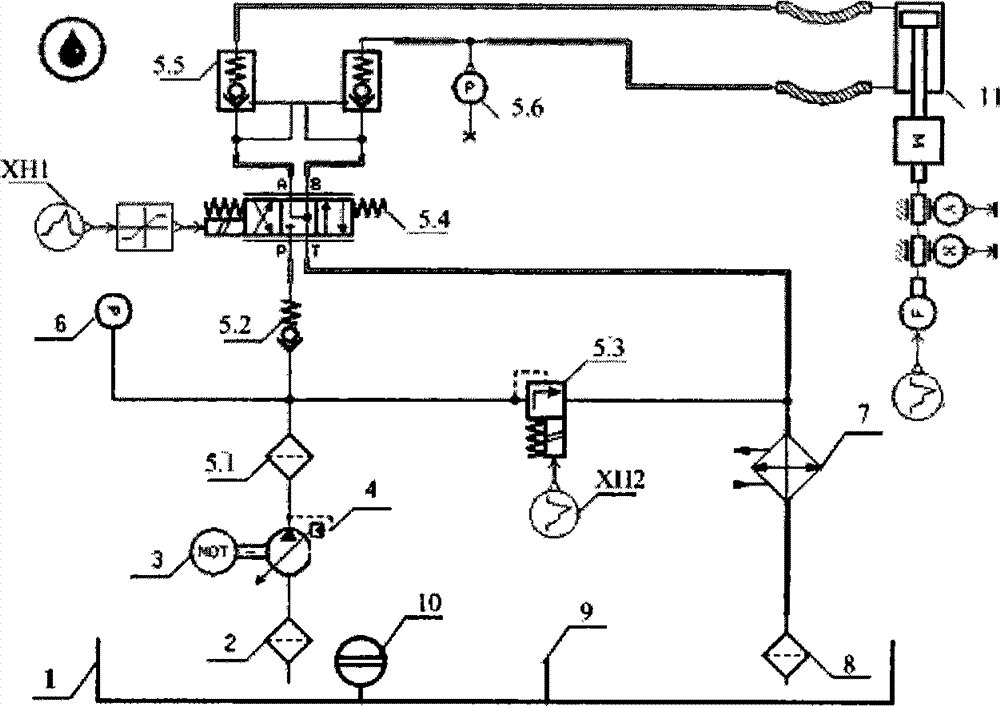

[0059] (1) The demoulding power and speed adjustment mechanism of a hydraulic power device for demoulding a composite launch tube

[0060] The so-called demoulding power refers to the thrust or pulling force of the demoulding actuator acting on the mandrel, and its size is determined by the product of the oil pressure entering the actuator and the effective area of the demoulding actuator perpendicular to the pressure direction (see formula (1)), when the effective area of the working chamber of the demoulding actuator is fixed, changing the system pressure through the electro-hydraulic proportional overflow valve can achieve the purpose of continuously adjusting the demoulding power; The ratio of the oil flow in the working chamber of the ejector to the effective area of the working chamber of the ejector actuator is determined. By adjusting the electro-hydraulic proportional reversing valve, the flow value entering the ejector actuator can be controlled (see formula (2)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com