A scanning probe and its manufacturing method

A scanning probe and manufacturing method technology, applied in scanning probe technology, scanning probe microscopy, measuring device and other directions, can solve problems such as high cost and complicated process, and achieve increased wear resistance, simple process method, high-resolution effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

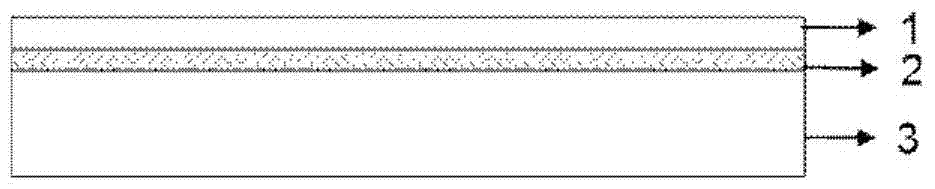

[0035] In this example, the base of the probe is 3.4mm long, 1.6mm wide, and the tip height is about 4um. The microcantilever is 200um long, 30um wide, and 4um thick. The method of making the scanning probe is as follows: Figure 1a ~ Figure 1h As shown, the specific process flow is as follows:

[0036] Step 1: adopt (100) oriented N-type SOI silicon wafer as the substrate for preparing the high-resolution, high-sensitivity, high-reliability scanning probe device, the substrate is composed of top layer silicon 1, buried oxide layer 2 and Bulk silicon 3, wherein the thickness of the top silicon is the sum of the height of the needle tip and the thickness of the micro-cantilever beam, that is, 8um, the thickness of the buried oxide layer is 1um, and the thickness of the bulk silicon is 400um, such as Figure 1a shown.

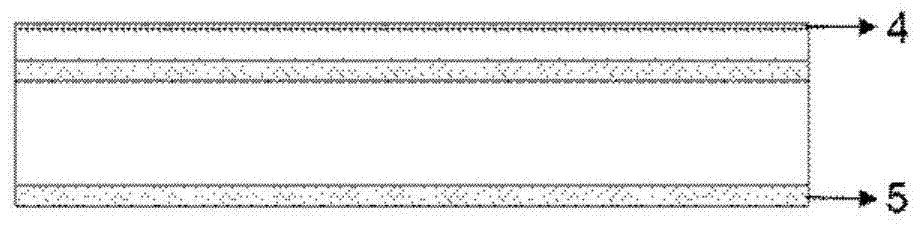

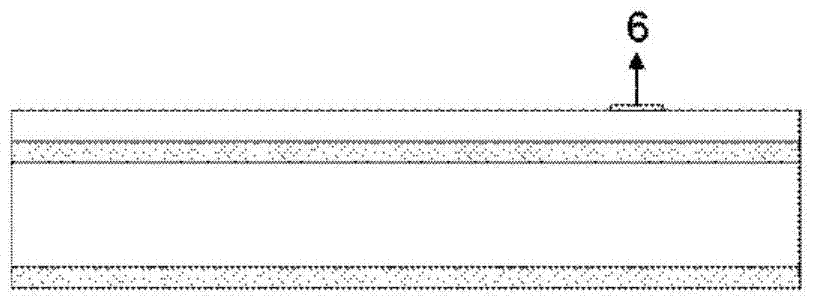

[0037] Step 2: Thermally oxidize the SOI sheet at 1000°C to form a thin silicon dioxide layer 4 with a thickness of about 300nm, which is used as a mask when e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com