Copying and splicing method of large-size plane diffraction grating

A diffraction grating and large-scale technology, which is applied in the field of replication and splicing of large-scale plane diffraction gratings, can solve the problems of high stability requirements of brackets, drift errors of adjustment and locking systems, etc., and achieves the effects of low cost, reduced difficulty and easy realization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

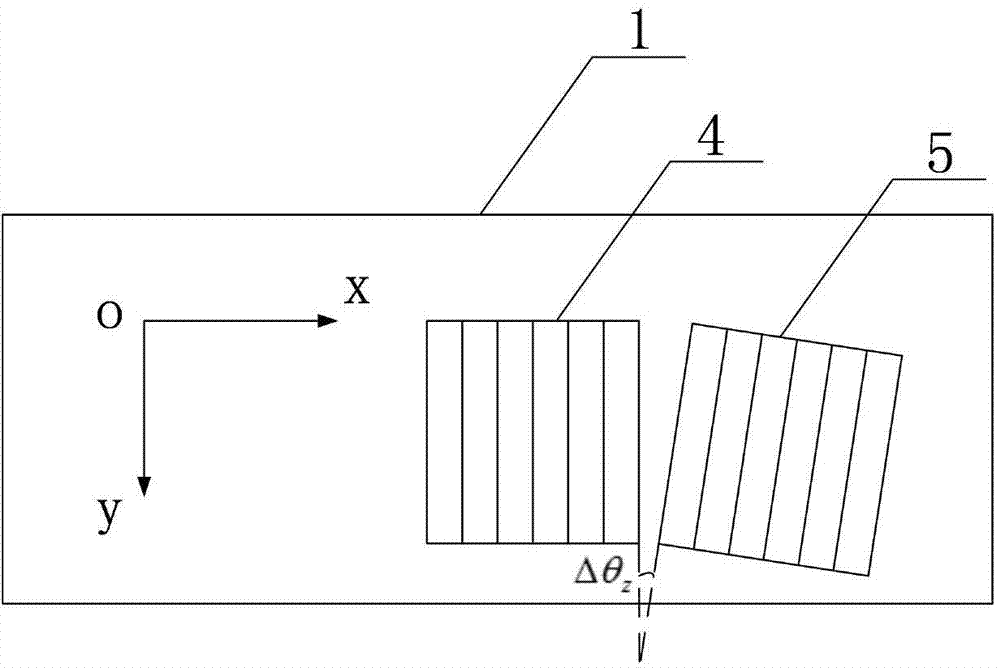

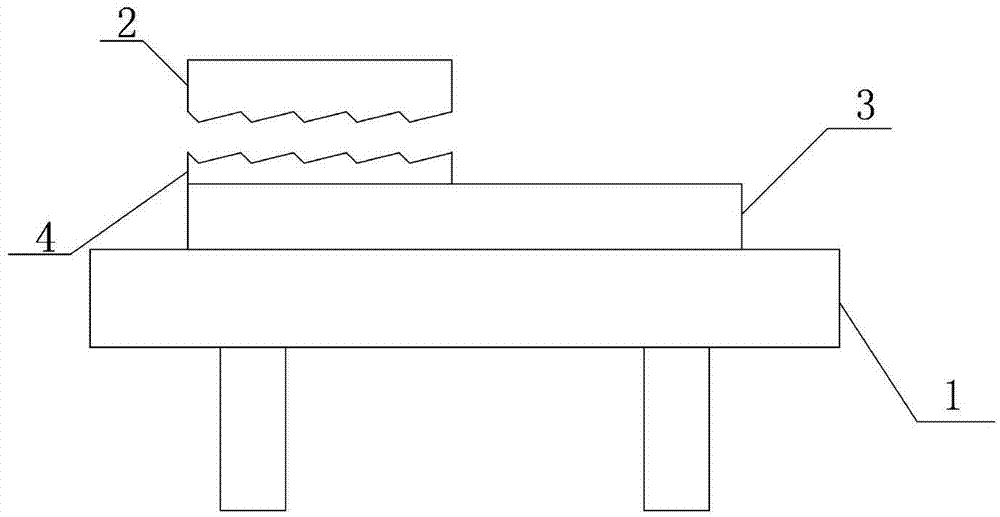

[0017] Specific implementation mode 1. Combination Figure 1 to Figure 3 To illustrate this embodiment, the copying and splicing method of a large-size plane diffraction grating includes steps,

[0018] S1. Using a piece of grating master 2, time-sharing copy twice in the adjacent area of the grating blank 3;

[0019] S2. Duplicate the first grating in the left area of the grating blank 3, and use epoxy resin glue as an adhesive in the duplication of the first grating. After the epoxy glue is cured, separate the first grating duplication The grating blank 3 and the grating master 2, so as to form a first replica grating 4 in the left area of the grating blank 3;

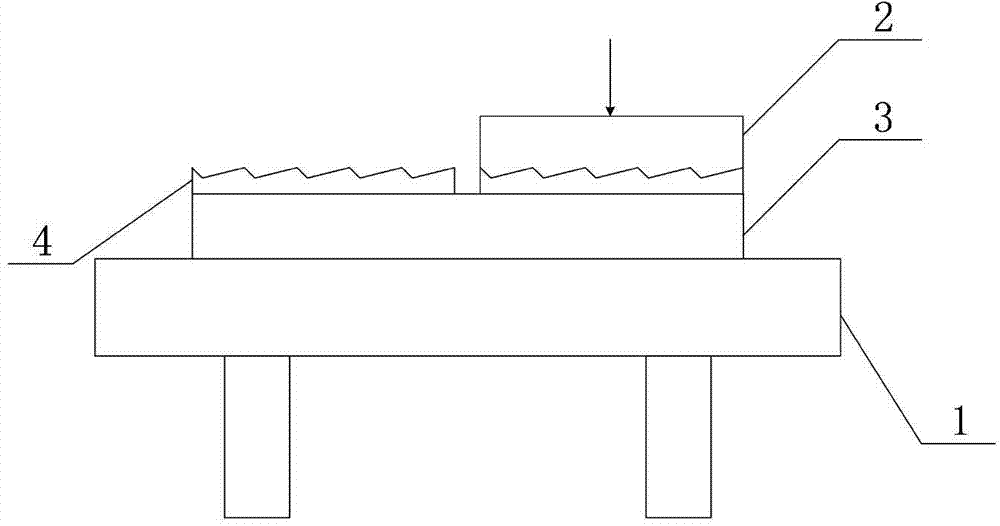

[0020] S3. Duplicate the second grating in the right area adjacent to the left area of the grating blank 3, detect the splicing error existing in the second grating duplication and the first duplicated grating during the duplication of the second grating, and adjust the splicing error and after the epoxy re...

specific Embodiment approach 2

[0026] Specific embodiment two, combine Figure 1 to Figure 3 This implementation mode is described. This implementation mode is an example of the method for copying and splicing a large-size plane diffraction grating described in the first specific implementation mode, including the following steps:

[0027] 1. First place the grating blank 3 on the vibration isolation platform 1, and then use a piece of grating master 2 to copy twice in the adjacent area of the grating blank 3 in time-sharing. When copying, the grating blank 3 is below, and the raster master 2 on top;

[0028] 2. Duplicate the first grating in the left area of the grating blank 3, and use epoxy resin glue as an adhesive in the first grating duplication. After the epoxy resin glue is cured, separate the first grating duplication The grating blank 3 and the grating master 2, so as to form a first replica grating 4 in the left area of the grating blank 3;

[0029] 3. Copy the second grating in the right...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com