Optical filter and manufacturing method thereof, touch liquid crystal display and manufacturing method thereof

A production method and filter technology, which are applied in the fields of filters, optics, instruments, etc., can solve the problems such as the requirements for the alignment accuracy of lamination, the thickness of the finished product, and the difficulty of the process, so as to avoid the alignment accuracy, improve the The effect of high rate and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

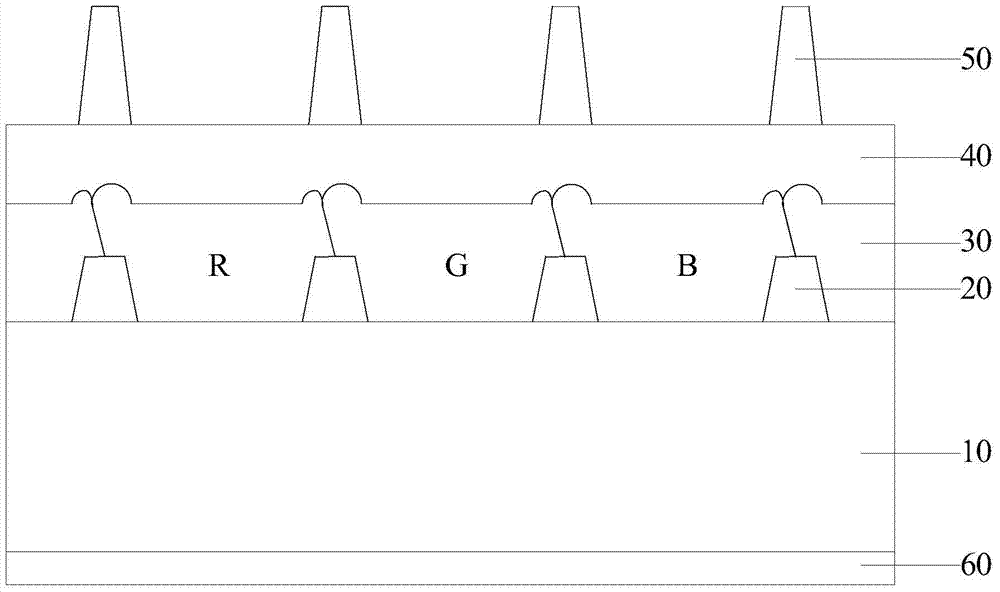

[0053] As mentioned in the background art section, touch LCDs with mainstream structures in the prior art generally have disadvantages such as complicated structure and process, high cost, long production cycle, and low production yield, and the most important thing is that they are thick.

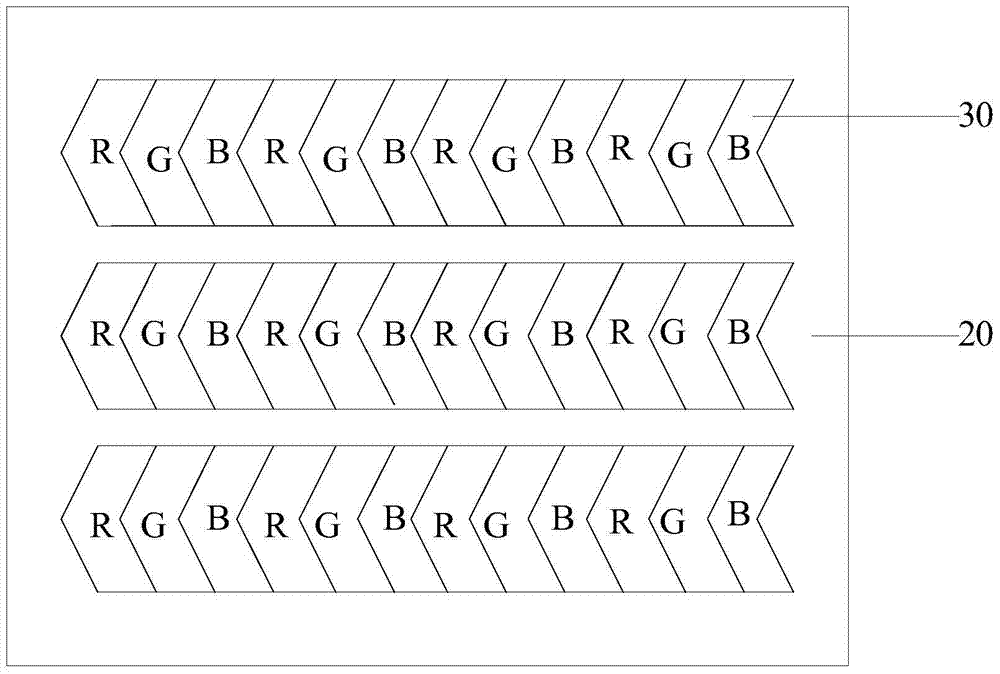

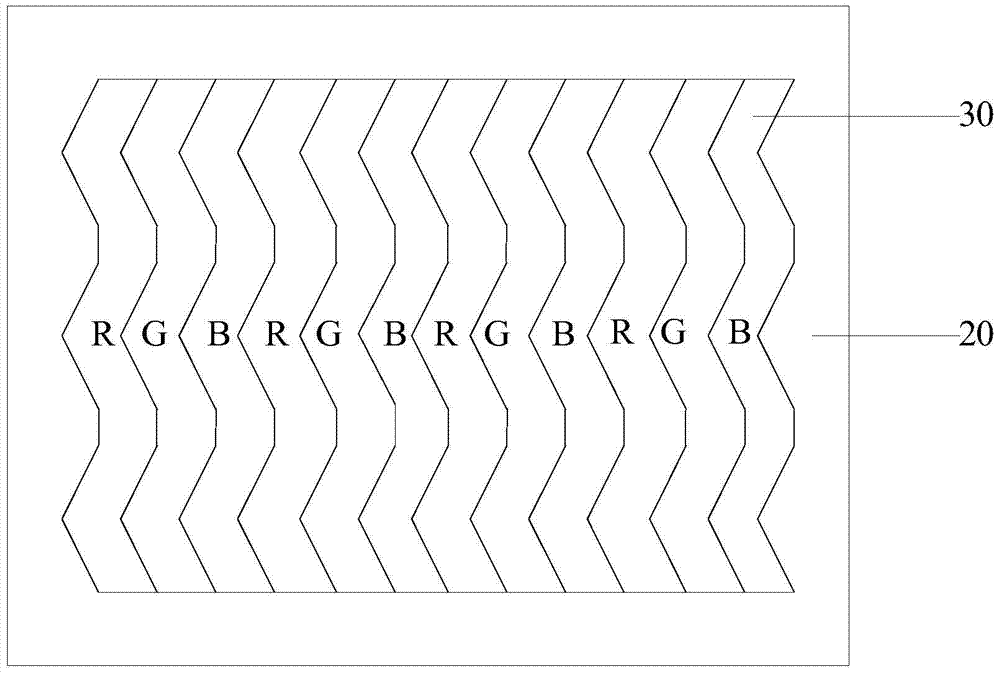

[0054] In view of the above problems, the present invention provides an optical filter integrated with a touch function and a manufacturing method thereof. The photoresist unit in the photoresist layer includes at least four kinds of photoresist, which changes the materials and materials of the two photoresist in the photoresist layer. A structure such that at least some of the first photoresists arranged along at least some of the same first directions are connected together and have conductivity, and at least some of the third photoresists arranged along at least some of the same second directions are connected together and have The second photoresist and the fourth photoresist are used t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com