Gluing method for double seams of space mirrors

A mirror and double-stop technology, which is applied in the field of space optical remote sensing, can solve the problems of reduced surface shape accuracy of space mirror, unstable stress distribution, uneven thickness of adhesive layer, etc. , The effect of uniform thickness of adhesive layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

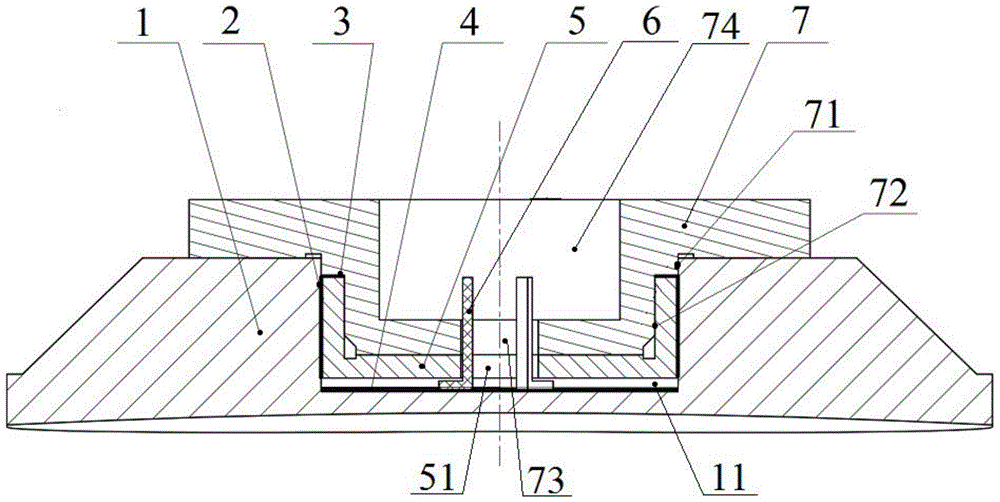

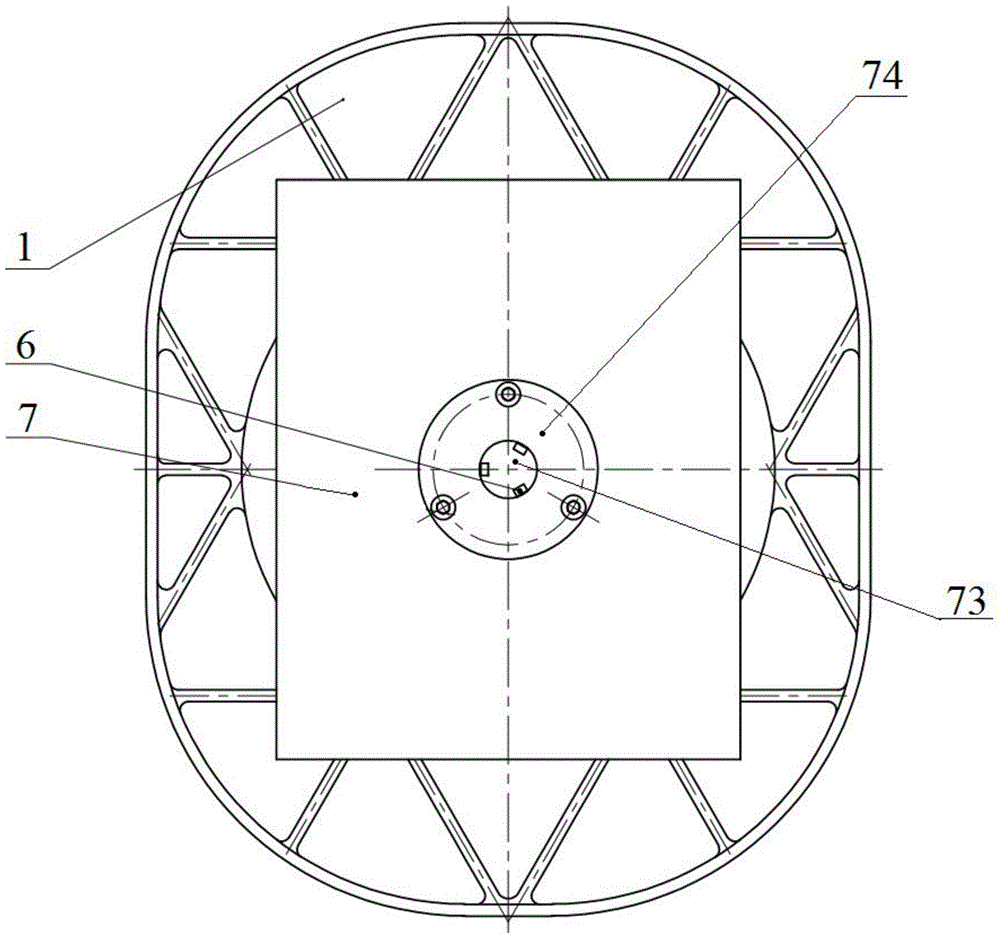

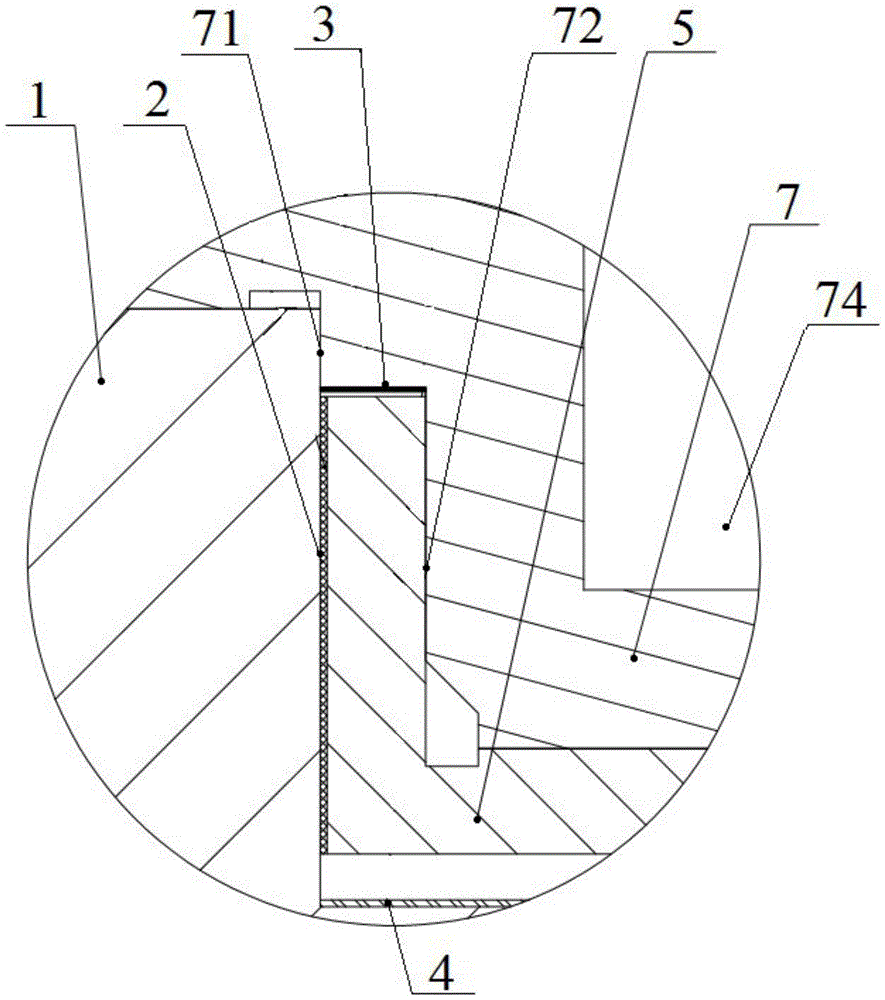

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0037] A method for gluing a space reflector with double seams according to the present invention, the method is realized by the following steps:

[0038] (1) First, use gauze dipped in acetone solution to wipe off the glue position on the side wall of the inner hole 11 of the space mirror 1 and the glue position on the outer side wall of the inlay 5 respectively, and then wipe the glue on the side wall of the space mirror 1 respectively. Apply epoxy resin glue with a thickness of 0.01 mm to 0.03 mm on the adhesive position on the side wall of the inner hole 11 and the adhesive position on the outer side wall of the inlay 5; the thickness of the applied epoxy resin adhesive is preferably 0.02 mm ;

[0039] (2) Place the space mirror 1 flat on the workbench, such as figure 1 As shown, first the bottom adhesive protective film 4 is tiled and pasted on the bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com