Automatic ultrasonic testing equipment for threaded hole zone of nuclear reactor pressure vessel

A pressure vessel and ultrasonic inspection technology, which is applied in nuclear reactor monitoring, reactors, nuclear engineering, etc., can solve the problems of no automatic inspection equipment, low quantification of inspection data, and increase the exposure dose of inspectors, so as to reduce the exposure dose and pollution risks, strong data quantification, and the effect of saving inspection time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below with reference to the drawings and embodiments.

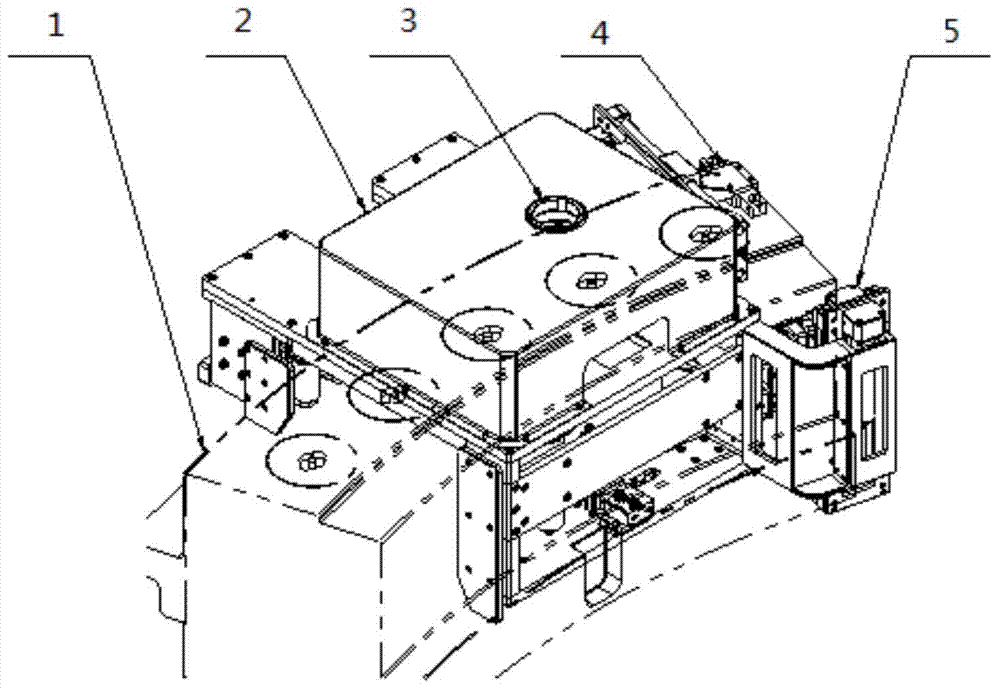

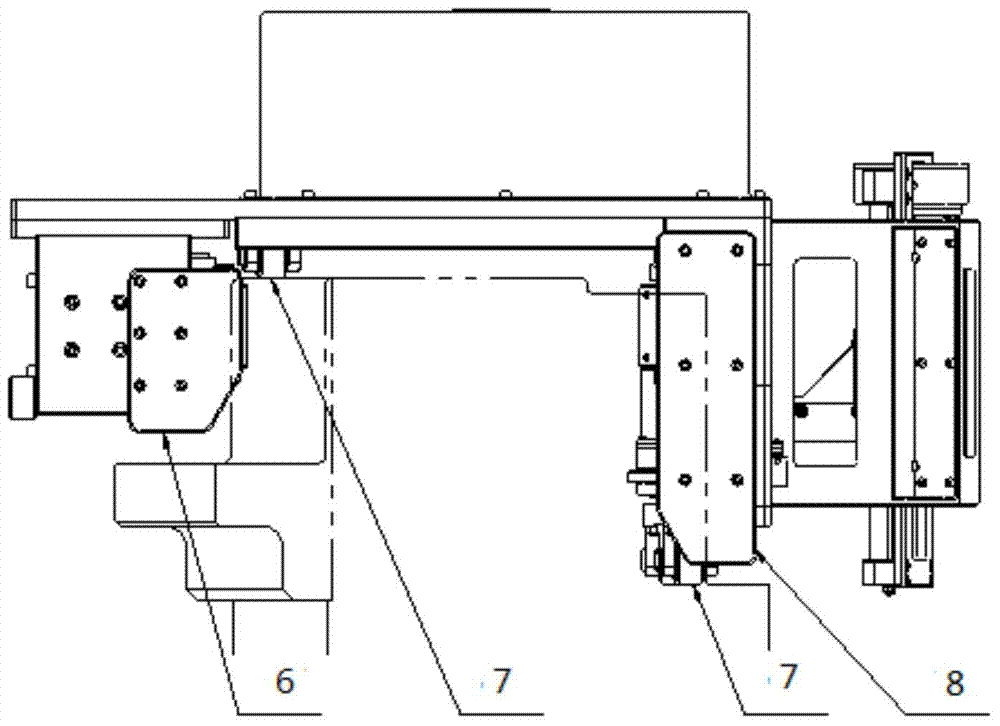

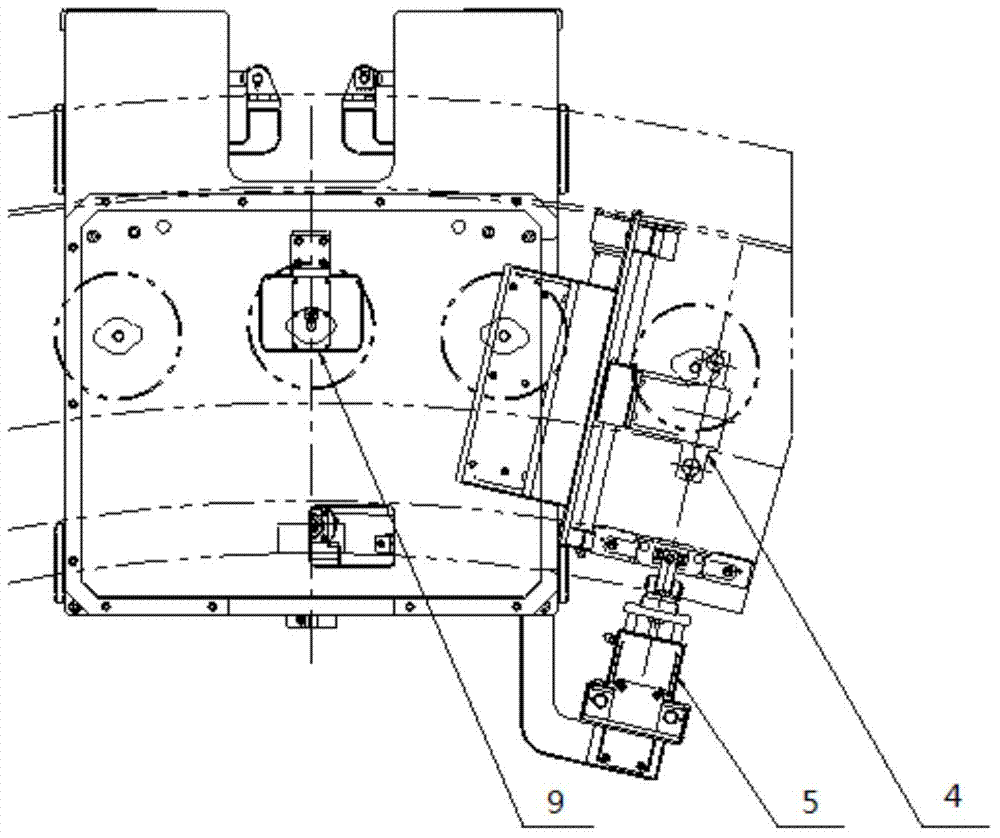

[0024] The automatic ultrasonic inspection equipment and principle of the threaded hole of the nuclear reactor pressure vessel involved in the present invention are as follows figure 1 , figure 2 , image 3 with Figure 4 Shown. Automatic ultrasonic inspection equipment for threaded holes of nuclear reactor pressure vessels includes: frame 2, lifting head 3, radial scanning assembly 4, axial scanning assembly 5, outer guide plate 6, vertical support wheel assembly 7, inner guide plate 8, The laser camera assembly 9, the driving wheel assembly 10, the encoder assembly 11, the circumferential support wheel assembly 12, the circumferential top pinch wheel assembly 13, the LED lamp 15, the camera 16 and the in-line laser 17.

[0025] The invention includes the following parts:

[0026] 1 Hoisting mechanism: the hoisting head 3 is installed on the frame 2. When checking the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com