A lateral high voltage device with multi-electrode structure

A lateral high voltage, multi-electrode technology, used in electrical components, semiconductor devices, circuits, etc., can solve the problem of increasing on-resistance of devices, and achieve the effects of reducing on-resistance, improving lateral withstand voltage, and increasing concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

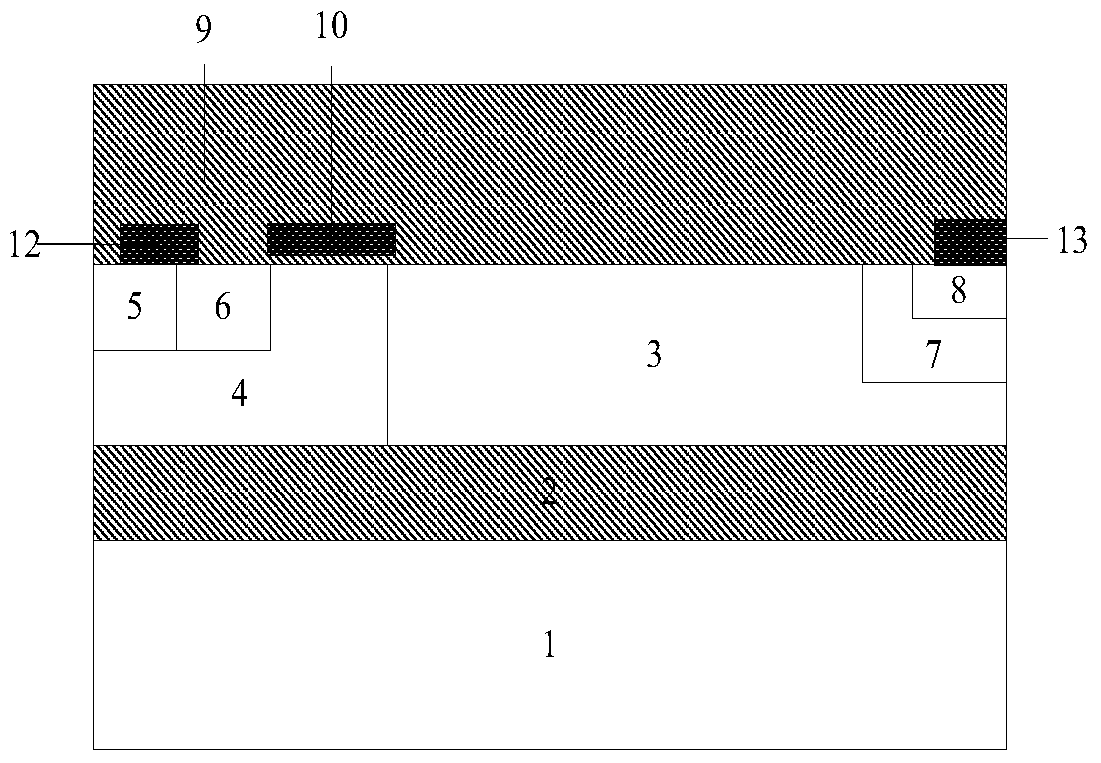

[0035] Such as figure 2As shown, a lateral high-voltage device with a multi-electrode structure includes a second-type impurity-doped semiconductor substrate 1; a buried oxide layer 2 formed on the second-type impurity-doped semiconductor substrate 1; formed on The first type doped impurity drift region 3 and the second type doped impurity well region 4 above the buried oxide layer 2; the second type doped impurity well region 4 formed in the second type doped impurity well region 4 The impurity contact region 5 and the first type doped impurity source region 6; the first type doped impurity well region 7 formed in the first type doped impurity drift region 3; the first type doped impurity well formed in the first type doped impurity well The first type doped impurity drain region 8 in the region 7; the dielectric layer 9 formed above the first type doped impurity drift region 3 and the second type doped impurity well region 4; in the dielectric layer 9 A polysilicon gate 10...

Embodiment 2

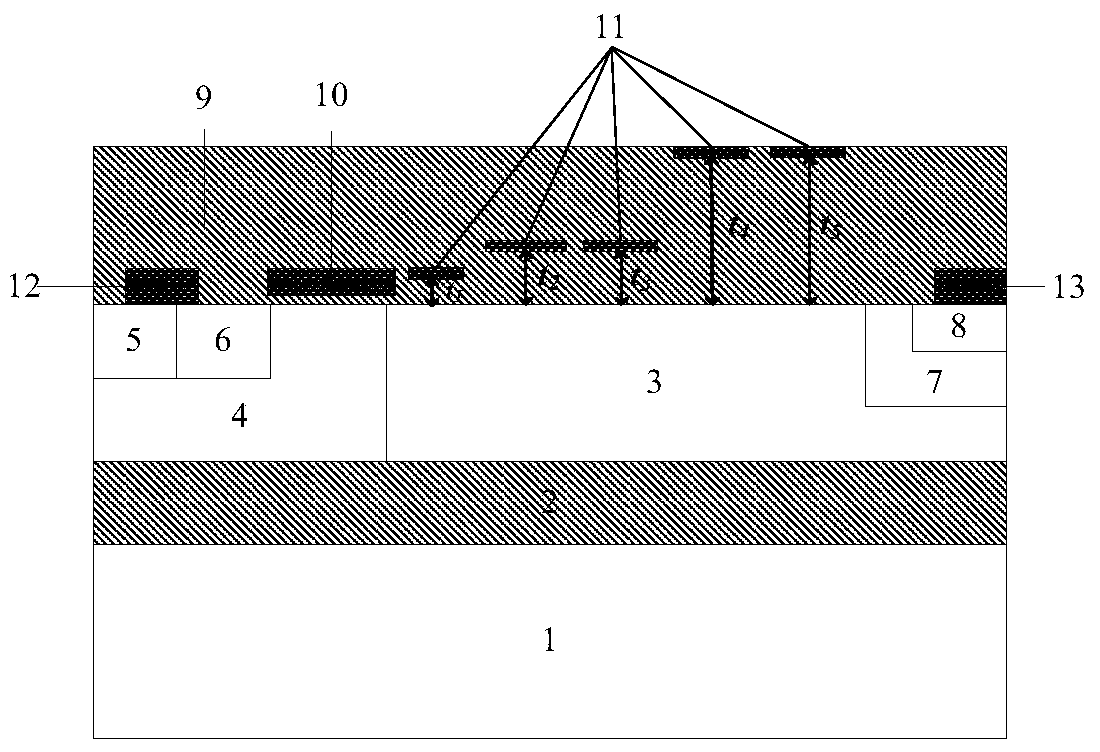

[0037] Such as image 3 As shown, the difference between the present embodiment and embodiment 1 is: the number of the electrodes is n, the height of the electrodes (that is, the distance between the lower surface of the electrode and the upper surface of the first type doped impurity drift region 3 ) has a rising trend along the direction from the second-type doped impurity well region 4 to the first-type doped impurity well region 7, and the electrodes 11 are always biased at different potentials and are farther away from the first-type doped impurity well region 7 Closer, the closer the potential of the electrode bias is to the potential on the drain region 8 of the first type doped impurity when the device breaks down.

Embodiment 3

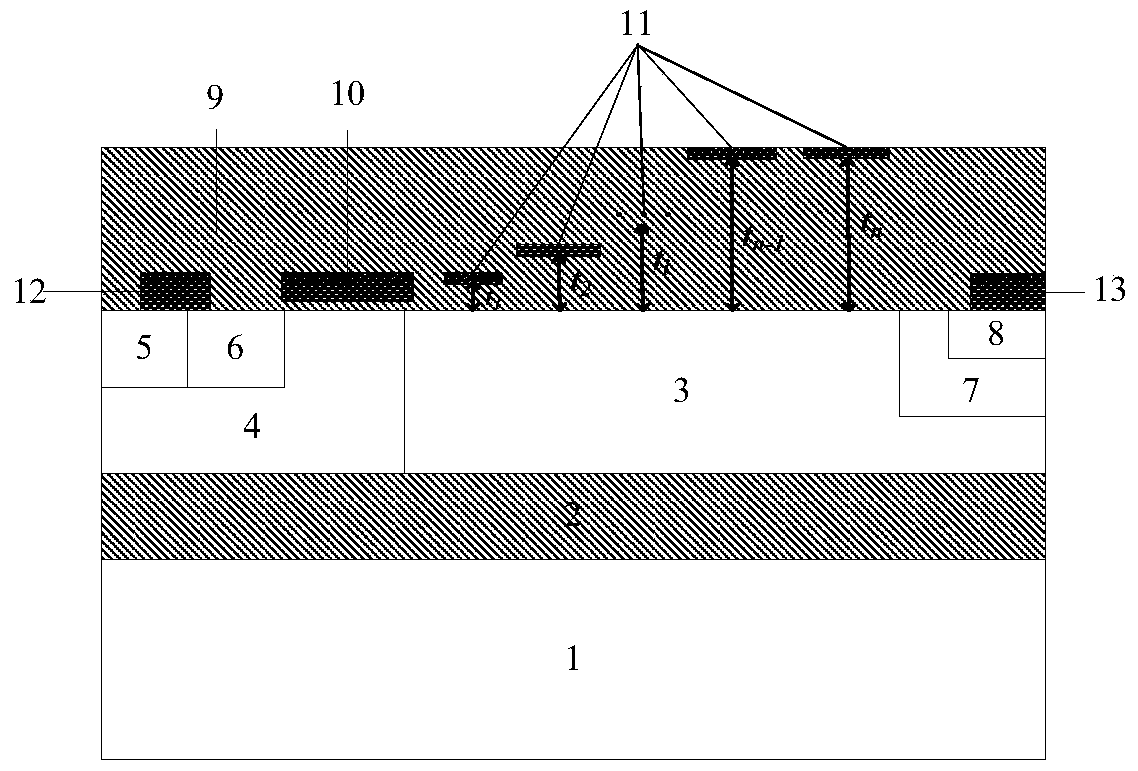

[0039] Such as Figure 4 As shown, the difference between this embodiment and embodiment 2 is that the SOI structure is replaced by a bulk silicon structure, that is, the buried oxide layer 2 is removed. It is illustrated that the present invention can be used for both SOI devices and bulk silicon devices.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com