IGBT module packaging structure of inverter

A module packaging and inverter technology, applied in the direction of electric solid-state devices, semiconductor devices, electrical components, etc., can solve the problems of reduced current capacity, complex phase outlets, high failure rate, etc., and achieve the reduction of common-mode interference current to ground and the Effects of improved capacity and lifetime, and reduced equivalent parasitic capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

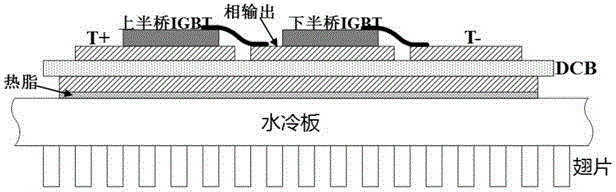

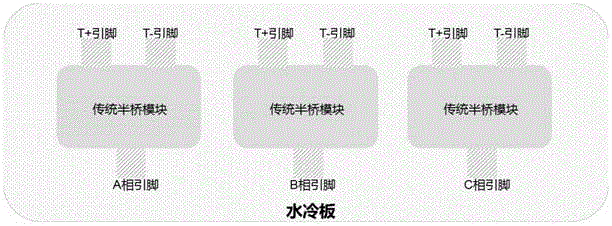

[0040] Inverter IGBT (Insulated Gate Bipolar Transistor) module package structure, such as Figure 5 , Figure 6 As shown, the inverter IGBT module includes three half-bridge IGBT modules of phase A, phase B and phase C, and each half-bridge IGBT module includes an upper half-bridge IGBT chip and a lower half-bridge IGBT chip, a first insulating ceramic substrate (DCB ), the second insulating ceramic substrate (DCB);

[0041] The surface area of the first insulating ceramic substrate is provided with a positive input terminal (T+) area and a negative input terminal (T-) area, and the positive input terminal (T+) area and the negative input terminal (T-) area are insulated from each other;

[0042] Each IGBT chip has three electrodes C, E, and G, of which the two electrodes C and E are used to conduct current, and G is the on / off control pin of the IGBT;

[0043] The lower surface of the upper half-bridge IGBT chip is the C pole, and the upper surface is the E pole;

[004...

Embodiment 2

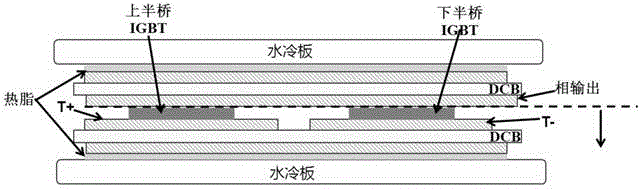

[0055] Based on the inverter IGBT (insulated gate bipolar transistor) module packaging structure of the first embodiment, such as Figure 7 As shown, the A-phase, B-phase and C-phase three half-bridge IGBT modules of the inverter IGBT module are arranged between three compartments formed by four identical water-cooled plates and clamped by the water-cooled plates.

[0056] In the packaging structure of the inverter IGBT module in Embodiment 2, both sides of the half-bridge IGBT module of each phase contact the water-cooled plate through thermal grease to form a double-sided heat dissipation structure, which is equivalent to two thermal resistances connected in parallel in thermodynamics, which can realize double-sided cooling , so the thermal resistance is only half of the traditional single-sided cooling system.

Embodiment 3

[0058] The package structure of the inverter IGBT (insulated gate bipolar transistor) module based on the second embodiment, such as Figure 8 As shown, 4 identical water-cooled plates are fastened together through four screws at the four corners.

[0059] Preferably, the water cooling plate is provided with a water inlet at the top and a water outlet at the bottom, the water inlets of each water cooling plate are respectively connected to the water inlet pipes, and the water outlets are respectively connected to the water outlet pipes.

[0060] Preferably, the water inlet and outlet pipes are sealed with the corresponding water inlet and outlet by O-rings.

[0061] Preferably, the water cooling plate is made of thin aluminum sheets, and folds or protrusions can be provided inside the water cooling plate to increase the heat dissipation area.

[0062] In the packaging structure of the inverter insulated gate bipolar transistor module of the third embodiment, the water flow en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com