A glued sports ball piece edge folding machine

A folding machine and sports technology, applied in sports accessories, balls, other household appliances, etc., can solve the problems of difficult folding and pasting, product quality fluctuations, and reduced ball quality, to ensure fineness and safety. performance, ensure speed and efficiency, and ensure the effect of hemming quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

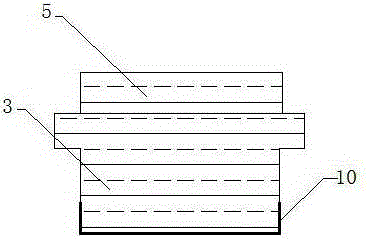

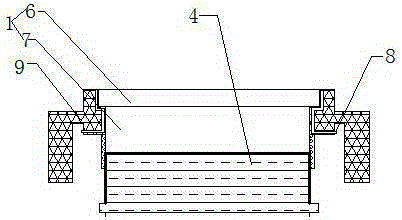

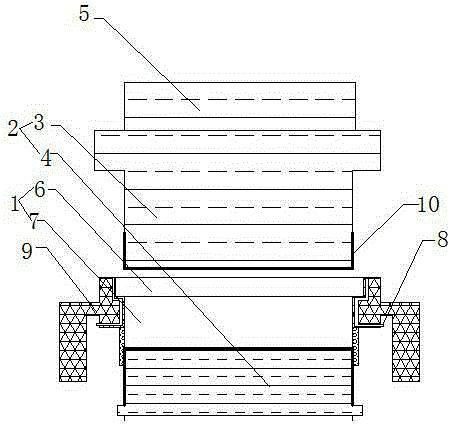

[0020] Such as Figure 1 to Figure 3 The shown glued sports ball sheet folding machine includes a mold 1 and a pressure head 2, and the pressure head 2 includes an upper pressure head 3 and a lower pressure head 4; the mold 1 is installed on the upper pressure head 3 and the lower pressure head Between the heads 4; the mold 1 is a shaping mold; the tail of the upper pressure head 3 and the lower pressure head 4 is equipped with a synchronous hydraulic device 5; the mold 1 is made of a large cavity 6 and a small cavity 7; A heating copper pipe 8 is installed inside the mold 1; legs 9 are integrally formed at both ends of the mold 1 .

[0021] Wherein, the outer side of the upper pressure head 3 and the lower pressure head 4 is covered with a layer of heating layer 10; the height of the small chamber 6 is twice as high as that of the large chamber; the synchronous hydraulic device 5 is composed of two air pipes connected to the same hydraulic platform; the The heating copper pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com