Roll coating type granite imitation coating material

A technique of imitating granite coating and roller coating, which is applied in the field of architectural coatings to achieve the effects of improving paint utilization, dense coating, and reducing loss and pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

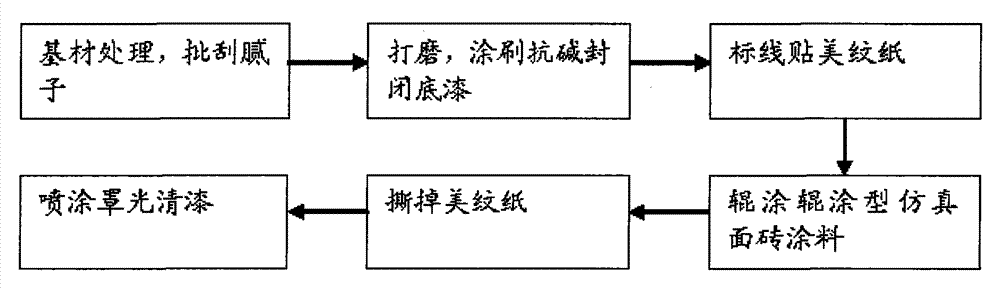

Method used

Image

Examples

Embodiment 1

[0032] In terms of components by weight, add 150 parts of water, 15 parts of ethylene glycol, 3 parts of dispersant, 951 parts of AMP, 50 parts of 2% hydroxyethyl cellulose solution, 30 parts of 10% inorganic gel, and 1 part of wetting agent Disperse evenly in the dispersion tank, then add 3 parts of defoamer, adjust the speed to 800-1200r / min and disperse for 20min, then adjust the speed to 600r / min, add 550 parts of natural colored sand and disperse for 3min, then add defoamer in order 4 parts of plastic agent, 50 parts of elastic polymer emulsion, 80 parts of rigid polymer emulsion, 6 parts of film-forming aid and stirred for 5 minutes, then added 7 parts of hydrophobically modified alkali-swellable thickening thickener, hydrophobically modified alkali-swellable association 2 parts of type thickener, 1.5 parts of fungicide and 20 parts of water are dispersed for 30 minutes, which is the finished roller coating type imitation granite coating A.

Embodiment 2

[0034] In terms of components by weight, 135 parts of water, 10 parts of ethylene glycol, 4 parts of dispersant, 1.5 parts of AMP95, 65 parts of 2% hydroxyethyl cellulose solution, 30 parts of 10% inorganic gel, 1.5 parts of wetting agent Add one part into the dispersing kettle to disperse evenly, then add 3 parts of defoamer, adjust the speed to 800-1200r / min and disperse for 20min, then adjust the speed to 600r / min, add 550 parts of natural colored sand and disperse for 3min, then add in order 4 parts of defoaming agent, 55 parts of elastic polymer emulsion, 70 parts of rigid polymer emulsion, 5 parts of film-forming aid and stir for 5 minutes, then add 7 parts of hydrophobically modified alkali-swellable thickening type thickener, hydrophobically modified alkali-swellable 3 parts of associative thickener, 1.5 parts of bactericide, and 20 parts of water are dispersed for 30 minutes, which is the finished roller coating imitation granite coating B.

Embodiment 3

[0036] In terms of components by weight, add 120 parts of water, 10 parts of ethylene glycol, 3 parts of dispersant, 952 parts of AMP, 50 parts of 2% hydroxyethyl cellulose solution, 30 parts of 10% inorganic gel, and 2 parts of wetting agent Disperse evenly in the dispersing tank, then add 3 parts of defoamer, adjust the speed to 800-1200r / min and disperse for 20 minutes, then adjust the speed to 600r / min, add 600 parts of natural colored sand and disperse for 3 minutes, then add defoaming agent in order 4 parts of plastic agent, 60 parts of elastic polymer emulsion, 50 parts of rigid polymer emulsion, 5 parts of film-forming aid and stirred for 5 minutes, then added 5 parts of hydrophobically modified alkali-swellable thickening thickener, hydrophobically modified alkali-swellable association 4 parts of type thickener, 1.5 parts of bactericide, and 10 parts of water are dispersed for 30 minutes, which is the finished roller coating type imitation granite coating C.

[0037] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| minimum film forming temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com