Preparation method for cross-linked sodium hyaluronate gel with asymmetric structure

A technology of cross-linking hyaluronic acid and sodium hyaluronate, which is applied in medical biomaterials and the medical field, can solve the problems of low utilization rate of cross-linking agent and difficulty in removing cross-linking agent, achieve long residual time in vivo, improve enzyme resistance The effect of reducing capacity and improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

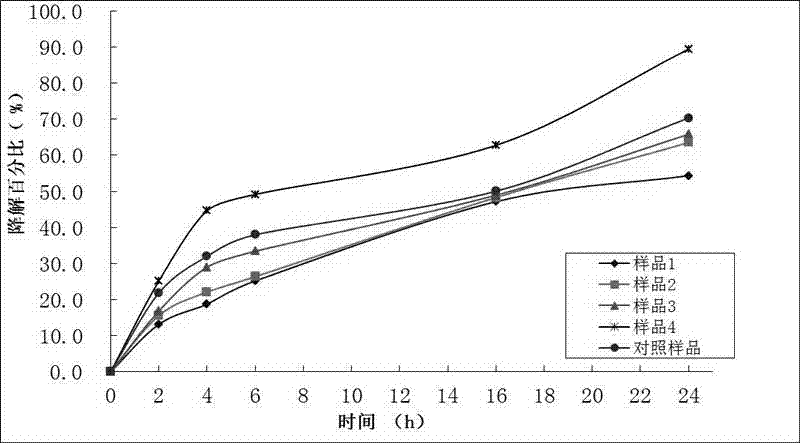

[0021] Prepare 20ml of 1% sodium hydroxide aqueous solution, add 0.02g of cross-linking agent BDDE, mix well, add 2.0g sodium hyaluronate, stir well, put it in a 10°C reaction box, set the dehydration rate to 3% / day , after reacting for 10 days, put it into a 40°C water bath, heat for 2 hours, take out the gel cut into about 0.5g in mass, put it in PBS buffer solution, and perform swelling dialysis to obtain cross-linked sodium hyaluronate gel. 20mg / ml.

[0022]

Embodiment 2

[0024] Prepare 20ml of 1% sodium hydroxide aqueous solution, add 0.01g of cross-linking agent BDDE, mix well, add 2.0g of sodium hyaluronate, stir well, put it in a 10°C reaction box, set the dehydration rate to 4% / day , after reacting for 10 days, put it into a 40°C water bath, heat for 2 hours, take out the gel cut into about 0.5g in mass, put it in PBS buffer solution, and perform swelling dialysis to obtain cross-linked sodium hyaluronate gel. 20mg / ml.

[0025]

Embodiment 3

[0027] Prepare 20ml of 1.5% sodium hydroxide aqueous solution, add 0.007g of cross-linking agent BDDE, mix well, add 2.0g of sodium hyaluronate, stir well, put it in a 10°C reaction box, set the dehydration rate to 5% / day , after reacting for 10 days, put it into a 40°C water bath, heat for 2 hours, take out the gel cut into about 0.5g in mass, put it in PBS buffer solution, and perform swelling dialysis to obtain cross-linked sodium hyaluronate gel. 20mg / ml.

[0028]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com