Novel environment-friendly high-temperature-resistant polyvinyl chloride cable material and preparation method thereof

A polyvinyl chloride cable and polyvinyl chloride resin technology, applied in the direction of circuits, electrical components, plastic/resin/wax insulators, etc. Impact, poor high temperature resistance and other issues, to achieve the effect of environmental protection, excellent high temperature resistance, good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

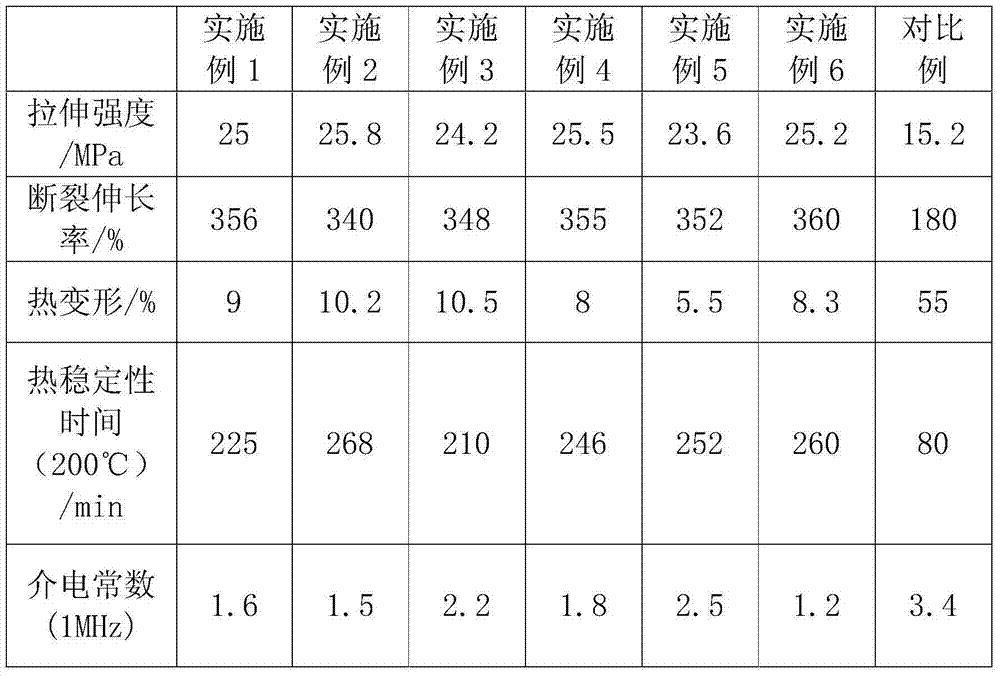

Examples

Embodiment 1

[0031] A new environment-friendly high temperature resistant polyvinyl chloride cable material, comprising the following components:

[0032] 50 parts of polyvinyl chloride resin,

[0033] 1 part of nano silicon oxide, 2 parts of BN nanosheets,

[0034] 1 part of bisphenol A, 2 parts of plasticizer,

[0035] 1 part of stabilizer, 2 parts of other additives.

[0036] Its preparation method comprises the following steps:

[0037] (1) Mix 50 parts of polyvinyl chloride resin, 1 part of nano-silica, 2 parts of BN nanosheets, and 2 parts of other additives into a high-speed kneader, knead for 10 minutes at 100 ° C, and add 1 part of bisphenol A , 2 parts of plasticizer, 1 part of stabilizer, continue kneading for 5 minutes to obtain the mixed material;

[0038] (2) extruding and pelletizing the mixed material obtained in the step (1) by a single-screw extruder, and drying to obtain an environment-friendly high-temperature-resistant polyvinyl chloride cable material.

[0039] W...

Embodiment 2

[0041] A new environment-friendly high temperature resistant polyvinyl chloride cable material, comprising the following components:

[0042] 80 parts of polyvinyl chloride resin,

[0043] 5 parts of nano silicon oxide, 6 parts of BN nanosheets,

[0044] 3 parts of bisphenol A, 5 parts of plasticizer,

[0045] 8 parts of stabilizer, 10 parts of other additives.

[0046] Its preparation method comprises the following steps:

[0047] (1) Mix 80 parts of polyvinyl chloride resin, 5 parts of nano-silica, 6 parts of BN nanosheets, and 10 parts of other additives into a high-speed kneader, knead for 20 minutes at 110 ° C, and add 3 parts of bisphenol A , 5 parts of plasticizer, 8 parts of stabilizer, and continue kneading for 10 minutes to obtain the mixed material;

[0048] (2) extruding and pelletizing the mixed material obtained in the step (1) by a single-screw extruder, and drying to obtain an environment-friendly high-temperature-resistant polyvinyl chloride cable material...

Embodiment 3

[0051] A new environment-friendly high temperature resistant polyvinyl chloride cable material, comprising the following components:

[0052] 55 parts of polyvinyl chloride resin,

[0053] 2 parts of nano silicon oxide, 3 parts of BN nanosheets,

[0054] 2 parts of bisphenol A, 3 parts of plasticizer,

[0055] 2 parts of stabilizer, 3 parts of other additives.

[0056] Its preparation method comprises the following steps:

[0057] (1) Mix 55 parts of polyvinyl chloride resin, 2 parts of nano-silica, 3 parts of BN nanosheets, and 3 parts of other additives into a high-speed kneader, knead for 12 minutes at 102 ° C, and add 2 parts of bisphenol A , 3 parts of plasticizer, 2 parts of stabilizer, continue kneading for 6 minutes to obtain the mixed material;

[0058] (2) extruding and pelletizing the mixed material obtained in the step (1) by a single-screw extruder, and drying to obtain an environment-friendly high-temperature-resistant polyvinyl chloride cable material.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com