Construction method of secondary direct discharge vacuum preloading treatment of newly dredged silt for land reclamation

A technology of silt filling and construction method, which is applied in soil protection, infrastructure engineering, construction, etc., can solve the problems of impeding seepage, the mud layer cannot meet the requirements for use, and the drainage board fails, so as to improve the bearing capacity of the foundation and reduce the Clogging risk, effect of foundation bearing capacity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with specific examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

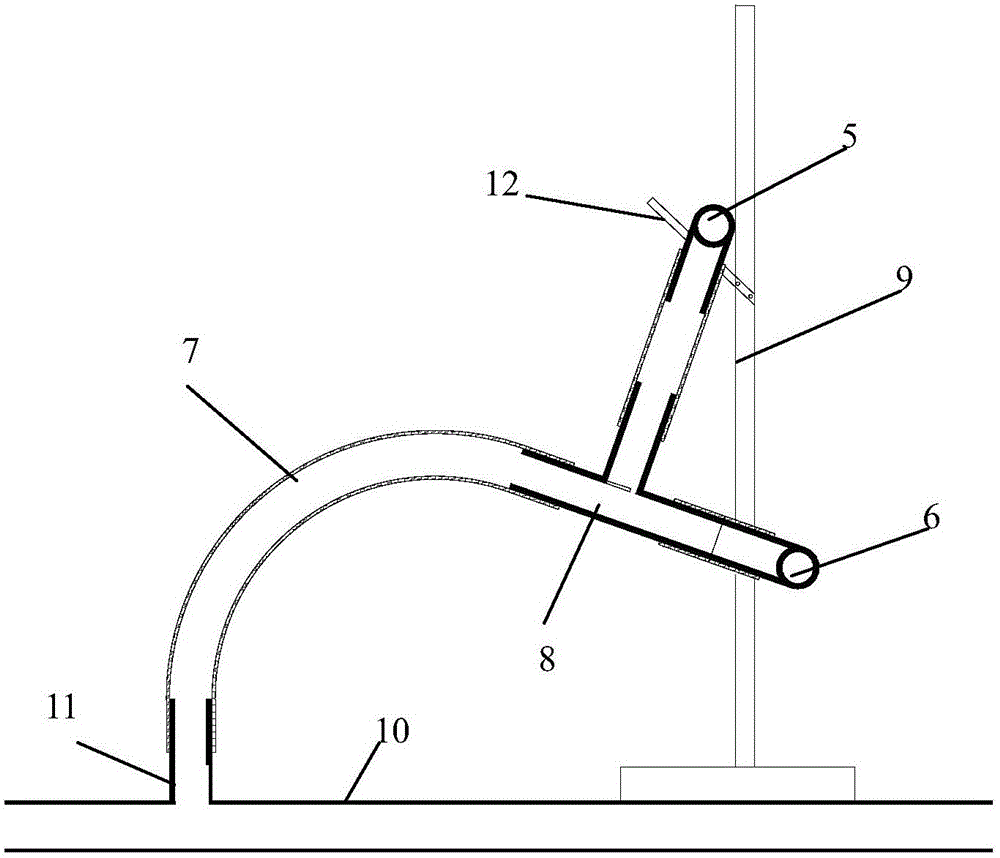

[0032] The construction method of the present invention for the secondary direct discharge vacuum preloading treatment of newly dredged silt land reclamation comprises a shallow drainage pretreatment step and a deep vacuum preloading step.

[0033] Among them, the shallow drainage pretreatment step includes the following sub-steps:

[0034] 1.1) Lay at least one layer of woven cloth and geotextile in turn on the newly dredged silt to build the manual operation cushion;

[0035] 1.2) Manually insert vertical drainage boards with a spacing of 0.7m-0.8m, square arrangement, and a depth of 4.5m into the mud; artificially inserting boards will disturb the dredged fill to a certain extent. The disturbed soil around the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com