Milling vibration punching type engineering slotting machine

A slotting machine and milling technology, which is applied in the field of milling, oscillating and smashing engineering slotting machines, can solve the time-consuming and labor-intensive process of connecting and dismantling the stroke drill pipe, the slotting machine cannot cut narrow grooves with a thickness, and the frictional resistance increases power. Consumption and other problems, to achieve the effect of saving engineering volume, convenient slag removal, and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

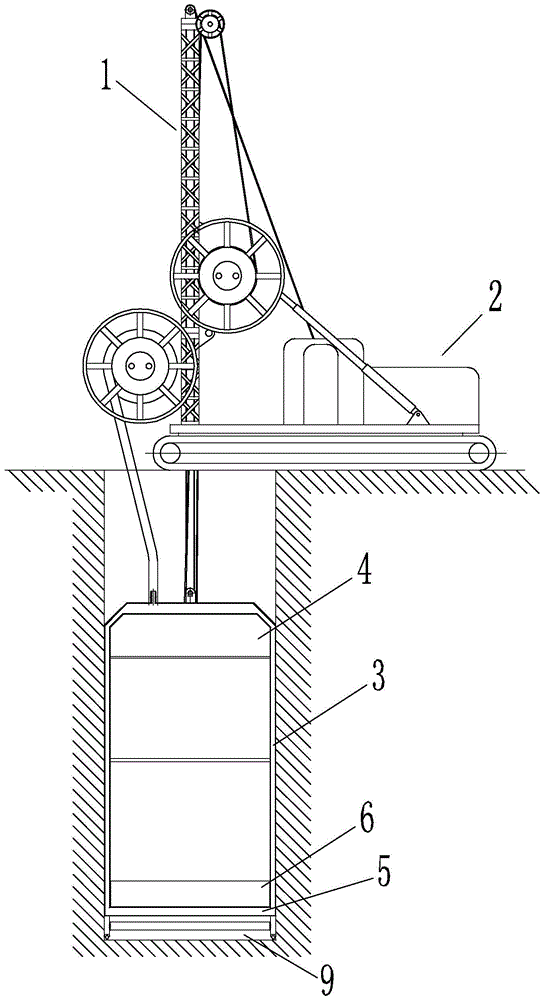

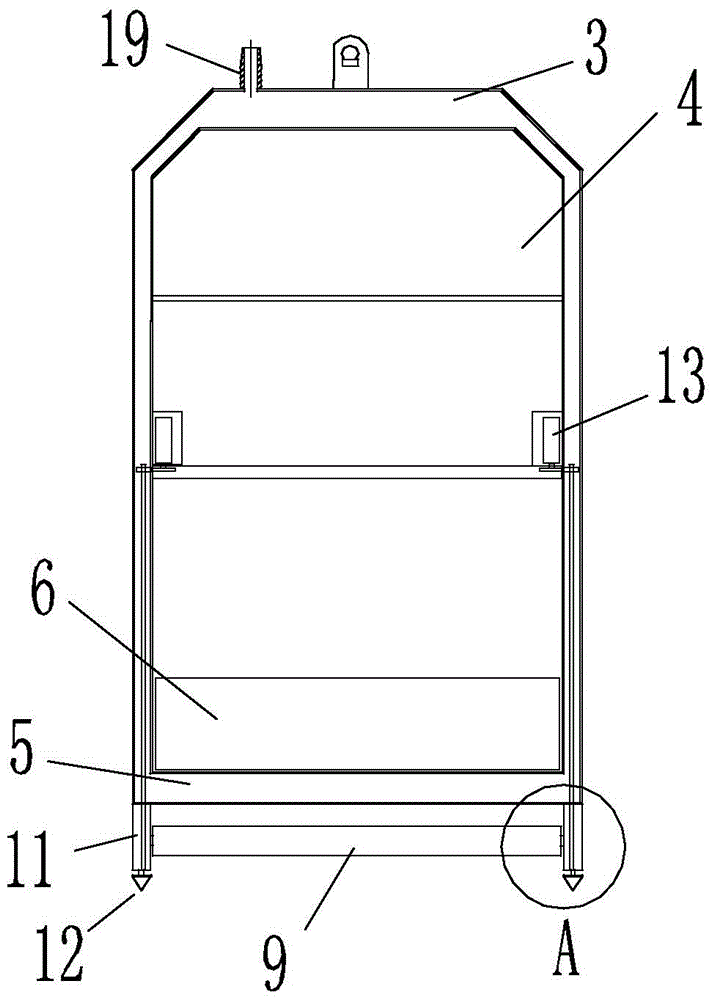

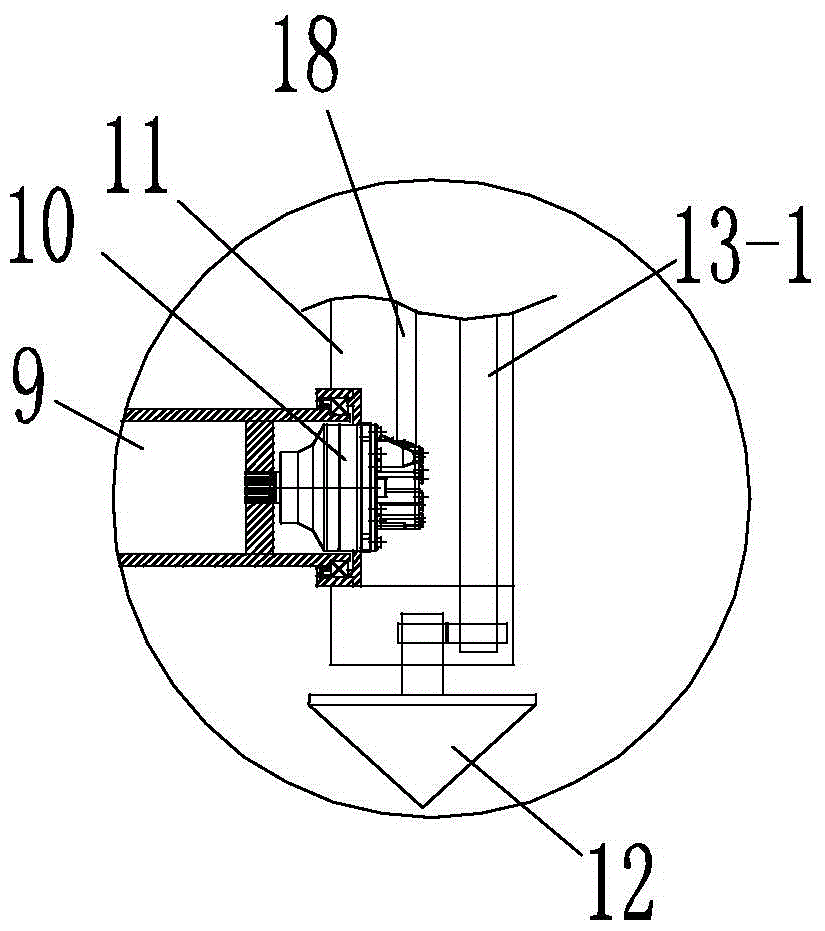

[0036] Such as Figure 1 to Figure 4 As shown, the milling vibration smashing type engineering slotting machine in this embodiment includes a traveling device 2 with a hoisting device 1 and a power system, and a monitoring device (not shown in the figure); The punching and milling device; the vibration punching and milling device includes a longitudinal guide frame 3, a rudder plate deviation correction device 4, a milling shaft 9 with a milling cutter, and a shock hammer 6; the rudder plate deviation correction device 4 is arranged in the guide frame 3, The milling shaft 9 is single and placed on the outside of the bottom beam 5 of the guide frame, the shock hammer 6 is located inside the bottom beam 5 of the guide frame and rises and falls on the upper end surface of the bottom beam 5; the axis of the milling shaft 9 is located in the plane where the guide frame 3 is located, And arranged horizontally; milling shaft 9 is driven by a horizontal hydraulic motor 10; milling sha...

Embodiment 2

[0047] Such as Figure 5 As shown, compared with embodiment 1, the differences of this embodiment are as follows:

[0048] The milling shaft 9 is divided into two sections, and is obliquely arranged on both sides of the vertical transmission rod 21 , driven by the vertical hydraulic motor 13 through the reversing device 22 . The milling range of the milling axis 9 covers the bottom of the guide frame 3 end columns.

[0049] The reversing device 22 is a bevel gear, the hydraulic motor 10 is connected with the vertical transmission rod 21 through the spur gear, the vertical transmission rod 21 drives the milling shaft 9 through the bevel gear 22, the bottom of the vertical transmission rod 21 and the positioning drill bit 12 covering the bevel gear 22 connect.

Embodiment 3

[0051] Such as Figure 6 As shown, compared with embodiment 1, the differences of this embodiment are as follows:

[0052] The milling axis 9 is segmented, including the horizontal milling axis 9-2 and the inclined milling axis 9-1 located on both sides of the horizontal milling axis 9-2; the end milling range of the inclined milling axis 9-1 covers the bottom end of the three end columns of the guide frame.

[0053] A vertical hydraulic motor 13 is adopted, and the reversing device 25 is a bevel gear. The hydraulic motor 13 is connected to the vertical transmission rod 21 through a spur gear, and the vertical transmission rod 21 drives the horizontal milling shaft 9-2 and the inclined milling shaft 9 through the bevel gear 25. -1, the bottom of the vertical transmission rod 21 is connected with the positioning drill bit 12 covered by the bevel gear. Hydraulic motor 13, vertical transmission rod 21, bevel gear reversing device 25 have two covers.

[0054] The vertical transm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com