Device and method for removing particles in nuclear reactor coolant

A technology for nuclear reactors and coolants, applied in nuclear engineering, radioactive purification, etc., can solve the problems of special working conditions and limitations of primary circuit pipelines, and achieve the effects of simple structure, low cost, and easy maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

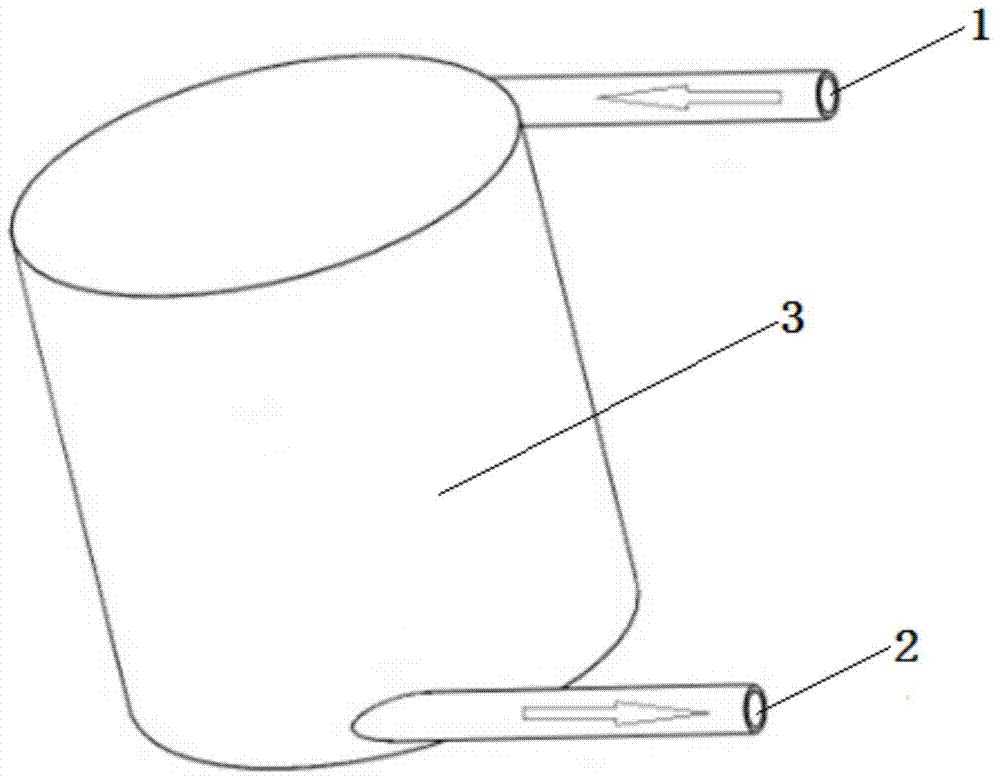

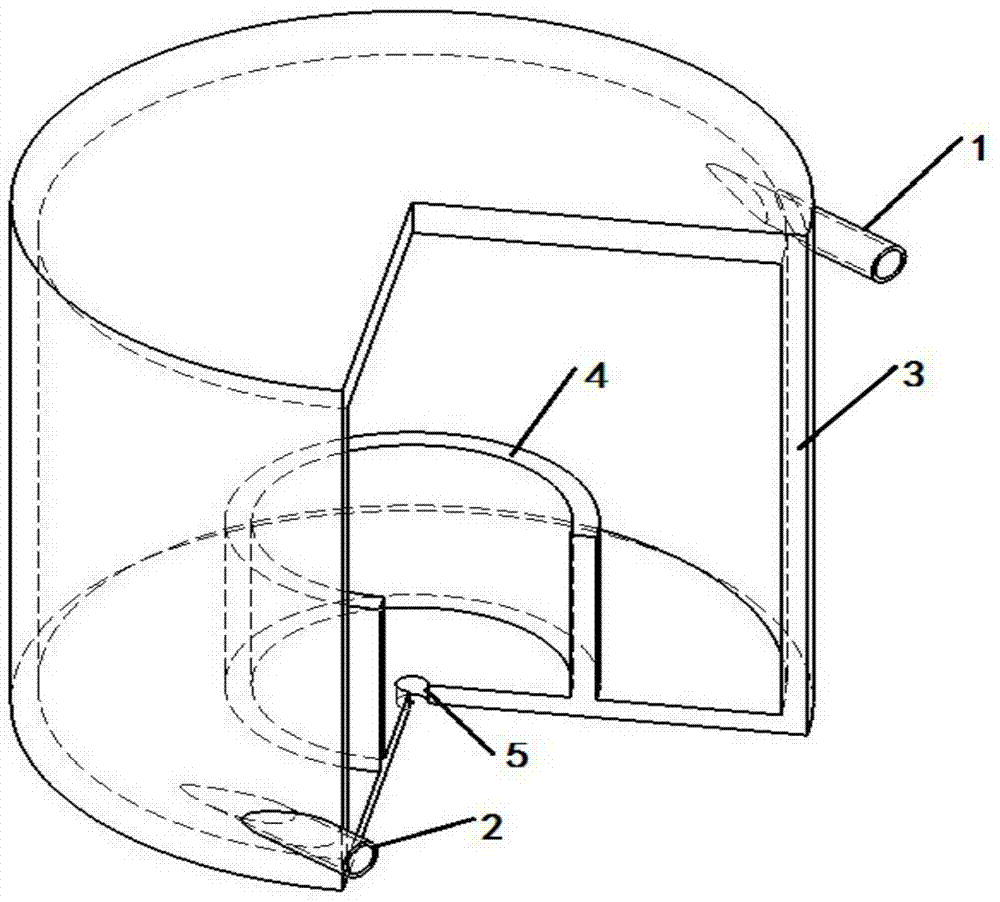

[0056] (1) The viscosity is 1095.1 μ Pa s, the particle volume fraction is 1.8%, and the heavy water whose fluid flow velocity is 2m / s is imported in the nuclear reactor coolant of the present invention from the fluid inlet pipeline of 0.02m according to a certain flow velocity. A device for removing particulate matter, the dimensions of the outer cylinder and the inner cylinder of the device are as follows:

[0057] The height of the outer cylinder is 2m and the diameter is 1m; the height of the inner cylinder is 0.1m and the diameter is 0.5m;

[0058] (2) After 5 minutes, take a sample from the fluid outlet pipeline with an internal diameter of 0.025m, and carry out the fine particle concentration test. The obtained result is: after passing through the removal device of the particle, the particle volume fraction in the fluid becomes 0.4%.

Embodiment 2

[0060] (1) the viscosity is 890.08 μ Pa s, the particle volume fraction is 2.5%, and the flow velocity is the water of 5m / s, from the fluid inlet pipeline of 0.04m input to two nuclear reactors according to the present invention connected in series from the inner diameter A device for removing particles in coolant, the dimensions of the outer and inner cylinders of the device are as follows:

[0061] The height of the outer cylinder is 3m and the diameter is 1.2m; the height of the inner cylinder is 0.2m and the diameter is 0.4m;

[0062] (2) After 5 minutes, take a sample from the fluid outlet pipeline with an internal diameter of 0.045m, and carry out the fine particle concentration test. The obtained result is: after passing through the removal device of the particle, the particle volume fraction in the fluid becomes 0.52%.

[0063] According to the experimental results, it is found that the device for removing particulate matter in the nuclear reactor coolant disclosed by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com