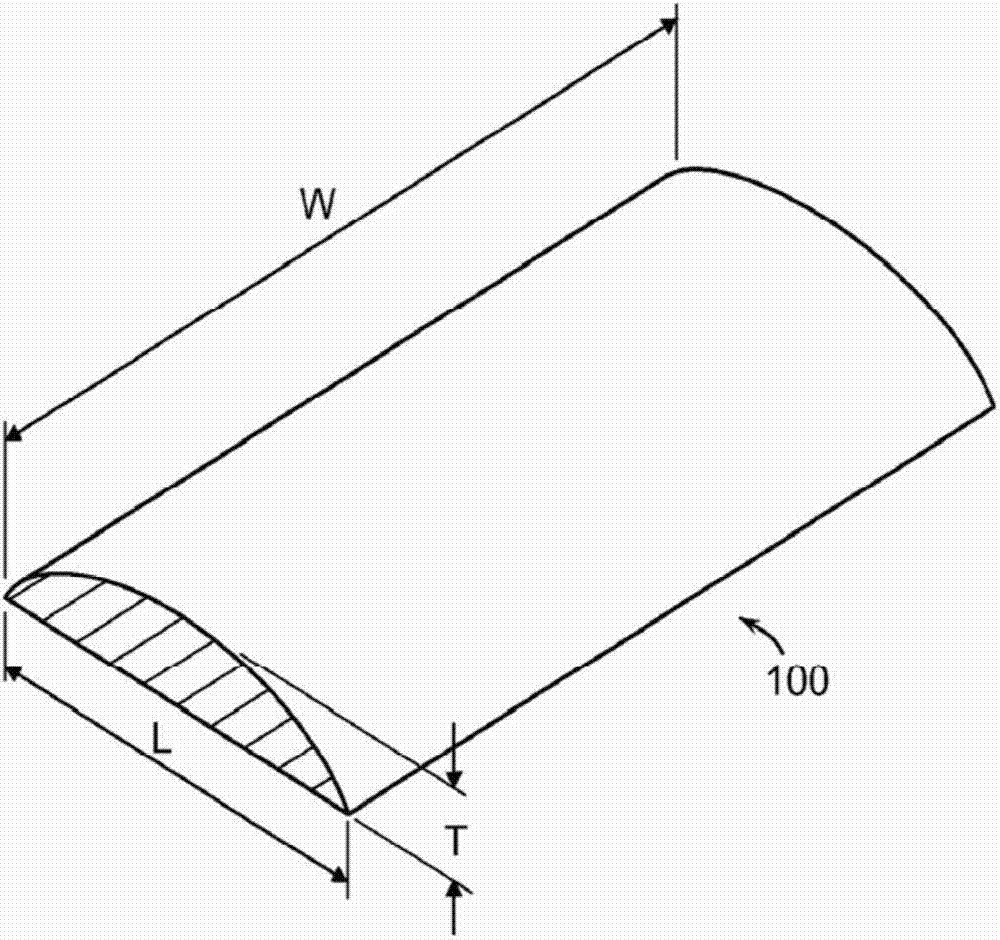

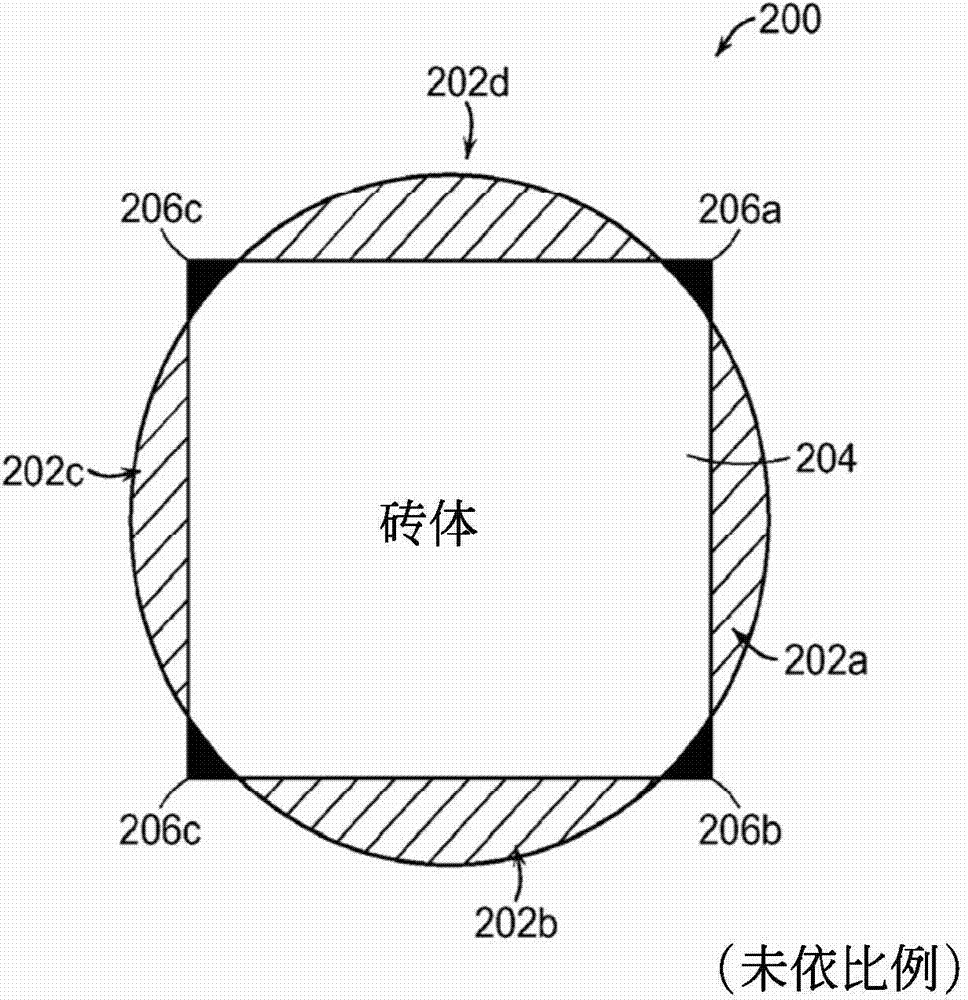

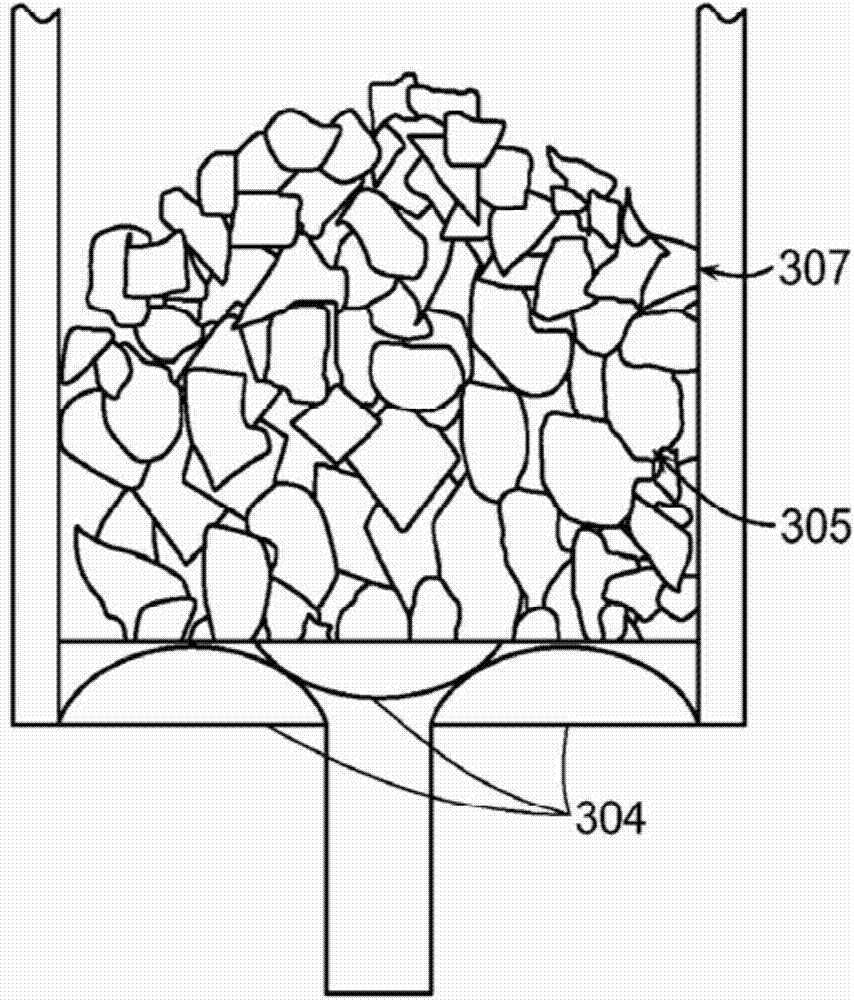

System and method of growing silicon ingots from seeds in a crucible and manufacture of seeds used therein

A silicon ingot and crucible technology, applied in the field of seed crystal manufacturing, can solve the problems of high manufacturing cost and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] definition

[0024] The invention is best understood by reference to the following definitions:

[0025] As used in the specification and claims, the singular forms "a" and "the" include plural references unless the context clearly dictates otherwise.

[0026] "Crystal growth equipment" as used herein means any device capable of heating and melting solid feedstocks such as silicon at temperatures generally greater than about 1000°C and promoting the resolidification of the resulting molten feedstock materials to form photovoltaic (PV) and / or semiconductor applications. Devices or equipment for crystalline materials such as monocrystalline silicon ingots.

[0027] A "trimming device" as used herein is any device capable of precisely cutting silicon into one or more pieces. The pruning device may be, for example, a knife, an automated saw, or any other well-configured device known in the art of precise cutting techniques.

[0028] The "squaring device" referred to here...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com