Calcium chloride-active carbon fibrofelt solid composite adsorbent and preparation method thereof

An activated carbon fiber felt and composite adsorption technology, applied in chemical instruments and methods, and other chemical processes, can solve problems such as fragmentation, weak heat and mass transfer capabilities, and low proportion of impregnated salts, so as to improve the adsorption rate and avoid liquid problem solving, strong capillary force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The invention provides a composite adsorbent based on a new material activated carbon fiber mat and a preparation method, which can have the advantages of high salt leaching rate, strong heat and mass transfer, and no liquid solution, and provide high-quality composite adsorbent for the air water intake system. Adsorbent for efficient adsorption and desorption.

[0023] Herein, a range indicated by "one value to another value" is a general representation which avoids enumerating all values in the range in the specification. Therefore, the description of a specific numerical range covers any numerical value in the numerical range and the smaller numerical range bounded by any numerical value in the numerical range, as if the arbitrary numerical value and the smaller numerical value are expressly written in the specification. same range.

Embodiment

[0026] 1. Preparation of calcium chloride-activated carbon fiber mat solid composite adsorbent

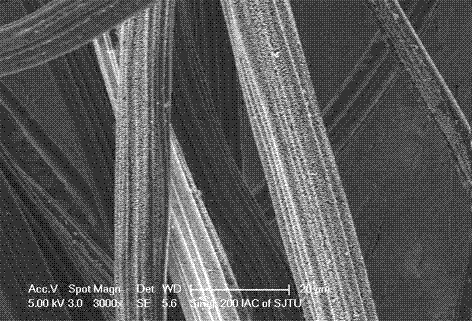

[0027] The specific surface area of activated carbon fiber felt used as raw material is 1380m 2 / g.

[0028] The preparation of calcium chloride-activated carbon fiber felt solid composite adsorbent is prepared by adjusting the appropriate calcium chloride salt concentration of 16.6%, 23%, 28.5%, and 33.3%, and adjusting the different suspension heights of activated carbon fiber felt (2cm-8cm). Find the most suitable composite adsorbent. The best concentration selection of calcium chloride salt through screening is 28.5%, and under this concentration, calcium chloride salt increment is maximum, is 0.862, and all can realize this when the concentration of calcium chloride salt is 28.5% ± 10%. The purpose of the invention; the suspended height of the activated carbon fiber felt is uniformly adopted at 6cm, because the capillary force can just in time make the activated carbon fib...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com