Handheld hydraulic drilling machine

A hydraulic drilling rig and drilling rig technology, applied in the field of hydraulic drilling rigs, can solve the problems of construction environment impact, equipment efficiency reduction, production capacity reduction, etc., and achieve the effects of improving the working environment, reducing maintenance costs, and reducing equipment costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

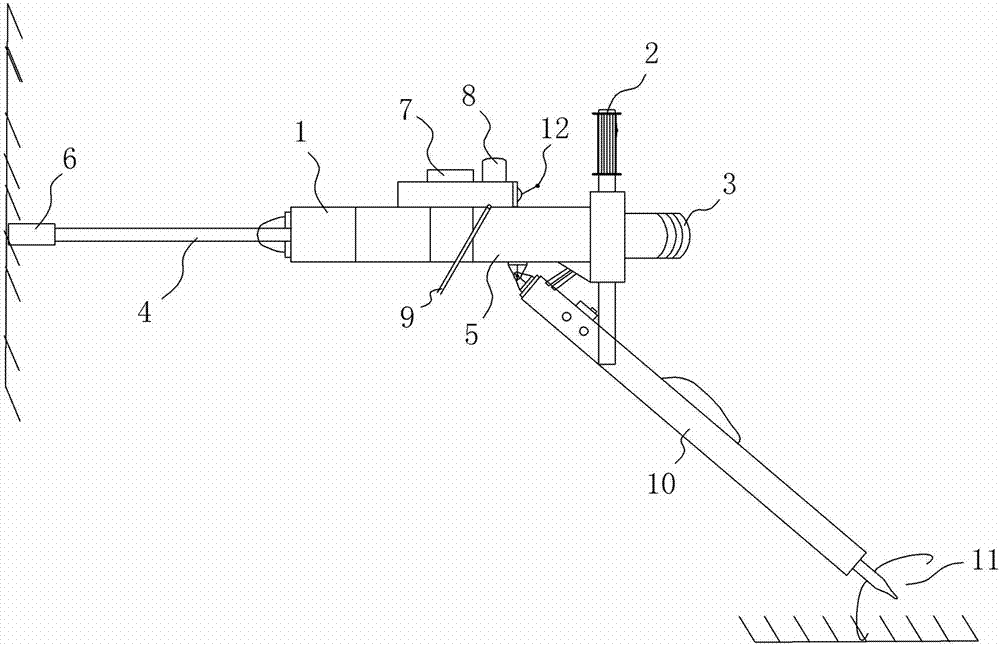

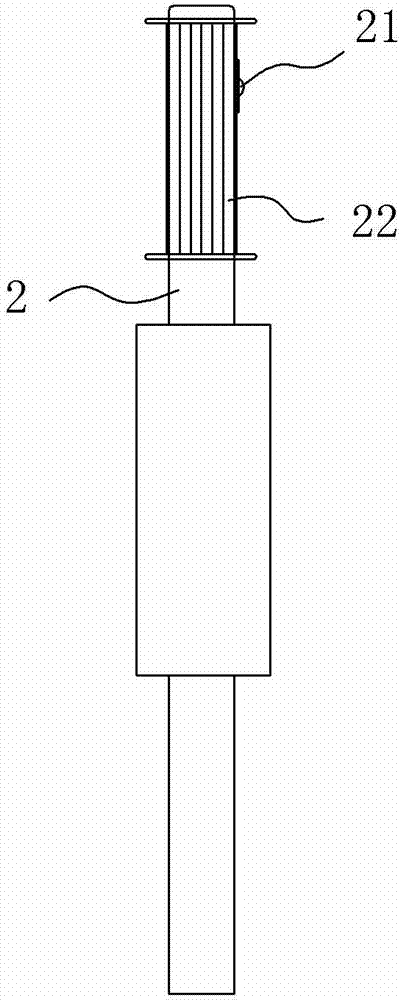

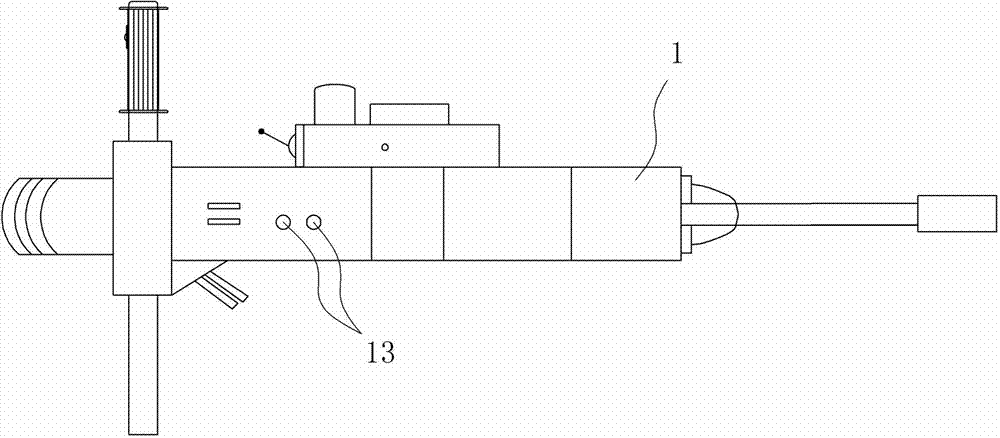

[0015] Such as figure 1 Shown, a kind of hand-held hydraulic drilling rig comprises drilling rig body 1, and the two sides of fuselage are equipped with grip bar 2 for hand grasping, and the two ends of fuselage are respectively equipped with hydraulic motor 3 and drilling rod 4, and fuselage is equipped with Driven by the hydraulic motor 3, the motor gearbox 5 that pushes the drill pipe to work, the end of the drill pipe 4 is equipped with a drill bit 6, the drill pipe has a flow channel connected to the inside of the fuselage, and the drill bit 6 has a water outlet channel for water supply and discharge. And the water outlet channel is connected with the water flow channel; the body is equipped with a water pump 7, a water pump motor 8 for driving the water pump, and a water inlet pipe 9 for water supply, and the water pump is connected to the water inlet pipe and pumps water to the water flow channel in the drill pipe; Also hinged is a telescopic hydraulic support leg 10 th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com