Production apparatus for improving durability of steel plastic composite tube

A technology for a steel-plastic composite pipe and a preparation device, which is applied in the production field of plastic-lined pipe fittings, can solve the problems of shortening the service life of the pipe, easy leakage of the sealing ring, separation and rupture of the inner layer of plastic, etc., so as to improve the service life, prolong the service life, Solve the effect of cracking and rusting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

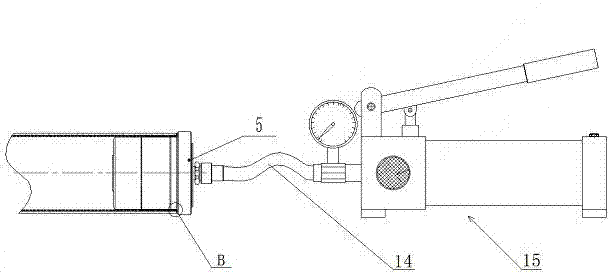

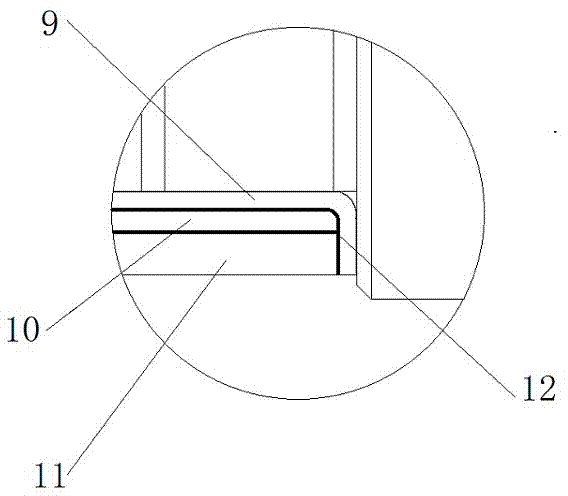

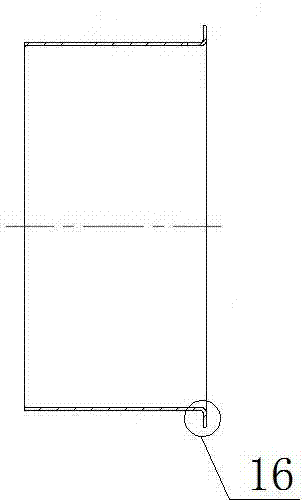

[0038] Such as figure 1 , 2 As shown in and 3, a preparation device for improving the durability of a steel-plastic composite pipe includes a steel-plastic composite pipe, a stainless steel bushing 9 and an expansion tool, and the steel-plastic composite pipe is composed of a plastic inner layer 10 and a galvanized steel layer 11, one end of the stainless steel bush 9 is provided with a flanging 16, the expansion tool includes a manual hydraulic pump 15 and an expander connected to each other through a hydraulic oil pipe 14, and the stainless steel bush 9 is embedded in the steel-plastic composite pipe port, the expander is embedded in the stainless steel bushing 9 at the port of the steel-plastic composite pipe, and the outer diameter of one end of the expander embedded in the stainless steel bushing 9 is adapted to the inner diameter of the stainless steel bushing 9 .

[0039] Such as Figure 4 with 5As shown, the expander includes an oil-passing mold core 1, an oil pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com