Water distribution apparatus for improving water distribution to prevent stink overflow

A water distribution device and odor technology, applied in biological treatment devices, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of affecting uniform water distribution, difficult level control, and uneven water distribution, etc. To achieve the effect of improving the treatment effect, increasing the contact surface, and increasing the dissolved oxygen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

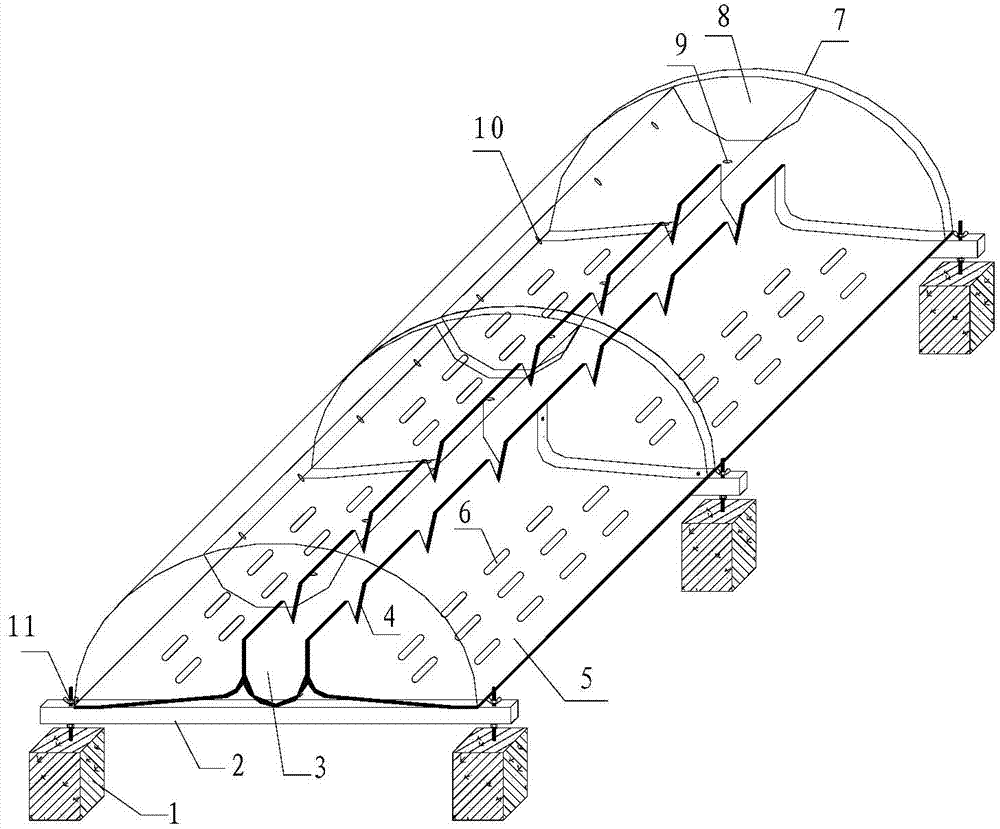

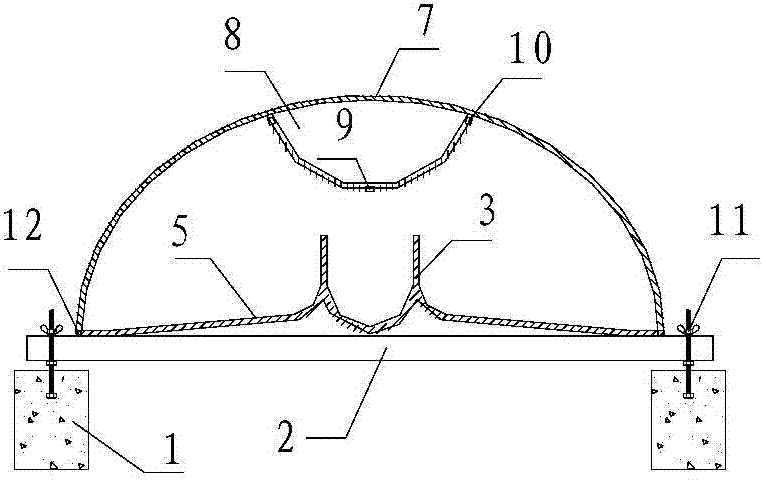

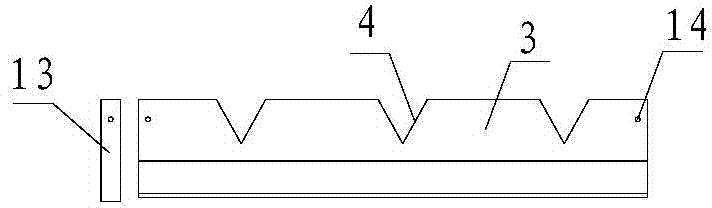

[0051] The water distribution device of the present invention, its structural schematic diagram is as follows Figure 1-7 shown. Such as figure 1 and Figure 6 As shown, the water distribution device includes a support column 1, a mounting frame 2, a water distribution weir groove 3, a distribution level plate 5 and an air collection cover 7.

[0052] The supporting column 1 is composed of a group of symmetrically arranged upright columns. In this embodiment, the upright column is a concrete pier, and the concrete pier is buried in the wetland filler. The top surface of each concrete pier is provided with pre-embedded bolts, namely bolts 11, and matched The adjusting nut is matched with the bolt and the nut for fixing and adjusting the installation frame 2 .

[0053] The mounting frame 2 is made of several aluminum alloy tubes fixed to each other, and the aluminum alloy tubes are connected to the top of the corresponding column through bolts and adjusting nuts. Therefore, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com