Method for removing mycotoxin in vegetable fat and application device

A technology of mycotoxins and vegetable oils, applied in the direction of fat oil/fat refining, fat production, etc., can solve the problems of unstable removal effect and low specificity of other toxins, and achieve continuous production, high nutrient content, high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1 A method for removing mycotoxins from vegetable oils

[0033] In the method, after the deacidification of liquid caustic soda, a device for detoxifying vegetable oil is used to perform caustic soda washing detoxification treatment on vegetable oil soda refining;

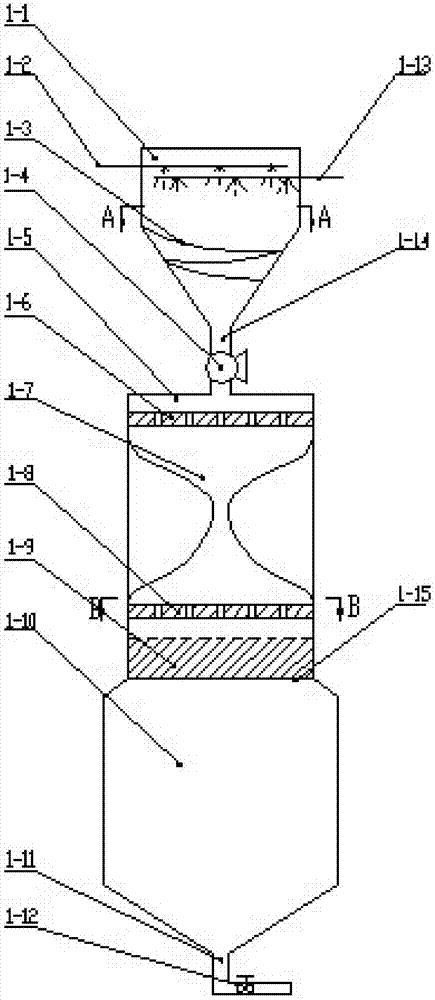

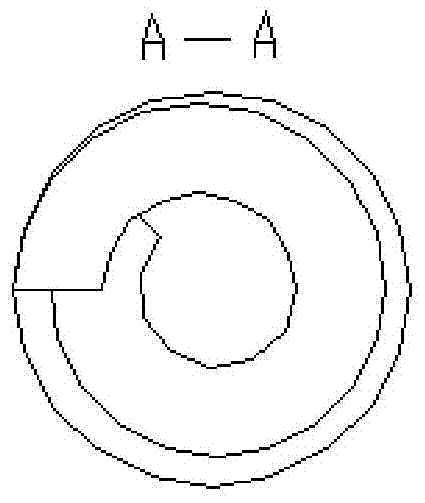

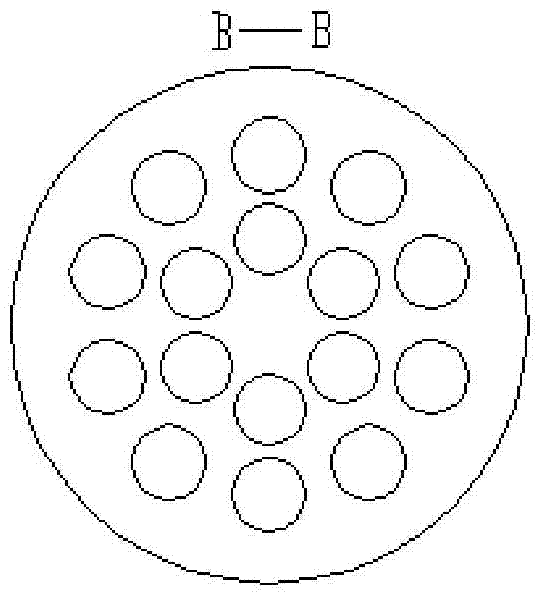

[0034] Such as Figure 1-3 As shown, the device for vegetable oil detoxification includes a premixing tank 1-1, an oil injection pipe 1-2, a spiral deflector 1-3, a high-pressure pump 1-4, a high-pressure jet mixing tank 1-5, Upper diffuser plate 1-6, Laval nozzle 1-7, lower diffuser plate 1-8, Pall ring layer 1-9, delay reaction tank 1-10, discharge pipeline 1-11, valve 1- 12. The lye nozzle 1-13, the connecting pipeline 1-14 and the supporting plate 1-15, the bottom of the premix tank 1-1 is conical, the taper is 1:1.000-2.414, the premix tank 1-1 It is flange-connected with the fuel injection pipe 1-2 and the lye nozzle 1-13, and the fuel injection pipe 1-2 and the lye nozzle 1-13 are respective...

Embodiment 2

[0035] Example 2 A method for removing mycotoxins from vegetable oils

[0036] The method adopts a vegetable oil microwave treatment adsorption detoxification device in the adsorption decolorization section of alkali refining to perform specific adsorption and detoxification of mycotoxins;

[0037] Such as Figure 4 As shown, the vegetable oil microwave treatment adsorption detoxification device includes a stainless steel microwave processor box 2-1, a high temperature resistant ceramic inner container 2-6, a detoxification tank 2-16, and the stainless steel microwave processor box 2-1 1. The inside is provided with a high-temperature resistant ceramic liner 2-6, and the top is provided with a stainless steel microwave processor case cover 2-11. Supports 2-3 are installed on both sides of each side below the high-temperature-resistant ceramic liner 2-6. The high-temperature ceramic liner 2-6, the microwave generator 2-2 is located below the high-temperature-resistant ceramic ...

Embodiment 3

[0038] Example 3 A method for removing mycotoxins from vegetable oils

[0039] On the basis of Example 2, such as Figure 4 As shown, the diameter of the oil spill pipe 2-12 is 2-3 times of the pipe diameter of the decolorized oil inlet pipe 2-7, and the horizontal height of the oil overflow pipe 2-12 is 50-80cm lower than the oil inlet pipe 2-7; The microwave frequency in the microwave generator 2 is 50GHz-300GHz; the number of electromagnetic waves is 10-20; the stainless steel microwave processor box 2-1, the stainless steel microwave processor box cover 2-11 and the detoxification tank 2-16 are all 304L Made of stainless steel; the rotating speed of the electric motor 2-14 is 15-30 rpm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com