Laser cladding preparation method for low-friction-coefficient Fe-base amorphous alloy coating

A technology of amorphous alloy and low friction coefficient, which is applied in the direction of superimposed layer plating, metal material coating process, coating, etc., can solve the problem of high friction coefficient, achieve simple process, wide application prospect, low friction coefficient Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

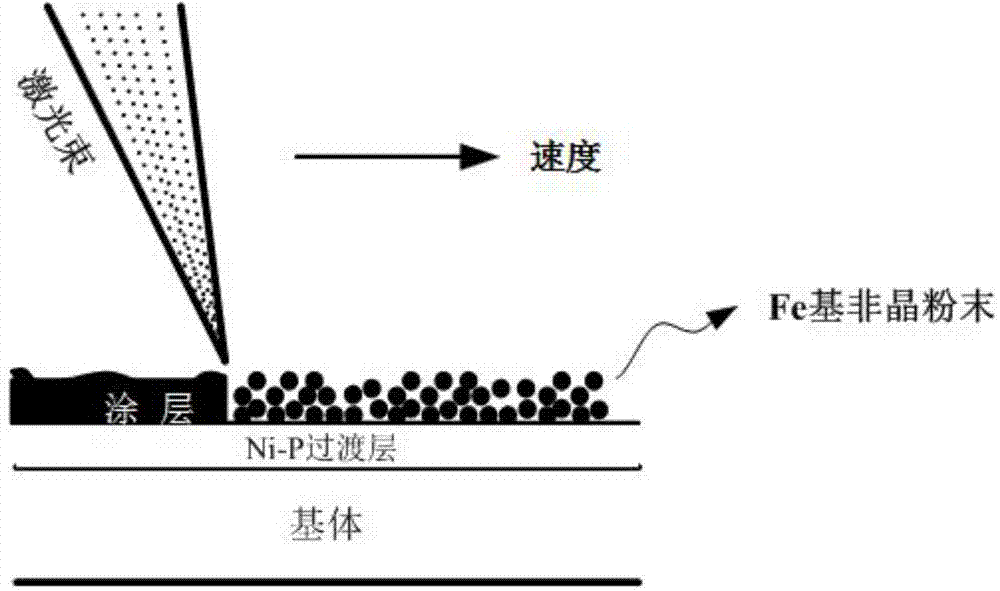

Embodiment 1

[0031] First, prepare 1L electroless Ni-P solution in a 2L beaker, the chemical formula of electroless Ni-P solution is 25g / L NiSO 4 ·6H 2 O, 25g / L NaH 2 PO 2 ·H 2 O, 26g / L Na 3 C 6 h 5 o 7 2H 2 O, 12g / L CH 3 COONa and 2mg / L CN 2 h 4S, the pH of the solution is 5.5; then, place the pretreated steel parts in the solution for constant temperature water bath treatment at 90°C, and the electroless plating time is 2 hours; after the electroless plating, take out the steel parts and rinse them with tap water And blow dry, obtain Ni-P amorphous transition layer on the surface of iron and steel parts, and through X-ray diffraction analysis, gained transition layer is amorphous state, and the mass percent content of P in Ni-P amorphous transition layer is 9.1% . The Fe-based amorphous alloy powder is preset on the surface of the Ni-P amorphous transition layer, and the Fe-based amorphous alloy powder is irradiated with a current of 240A, a pulse width of 2.5ms, a pulse freq...

Embodiment 2

[0033] First, prepare 1L electroless Ni-P solution in a 2L beaker, the chemical formula of electroless Ni-P solution is 25g / L NiSO 4 ·6H 2 O, 25g / L NaH 2 PO 2 ·H 2 O, 26g / LNa 3 C 6 h 5 o 7 2H 2 O, 12g / LCH 3 COONa and 2mg / L CN 2 h 4 S, the pH of the solution is 6; then, place the pretreated steel parts in the solution for constant temperature water bath treatment at 85°C, and the electroless plating time is 2 hours; after the electroless plating, take out the steel parts and rinse them with tap water And blow dry, obtain Ni-P amorphous transition layer on the surface of iron and steel parts, and through X-ray diffraction analysis, gained transition layer is amorphous state, and the mass percent content of P in Ni-P amorphous transition layer is 9.1% . The Fe-based amorphous alloy powder is preset on the surface of the Ni-P amorphous transition layer, and the Fe-based amorphous alloy powder is irradiated with a current of 270A, a pulse width of 2.5ms, a pulse frequen...

Embodiment 3

[0035] First, prepare 1L electroless Ni-P solution in a 2L beaker, the chemical formula of electroless Ni-P solution is 25g / L NiSO 4 ·6H 2 O, 25g / L NaH 2 PO 2 ·H 2 O, 26g / LNa 3 C 6 h 5 o 7 2H 2 O, 12g / LCH 3 COONa and 2mg / L CN 2 h 4 S, the pH of the solution is 5.7; then, place the pretreated steel parts in the solution for constant temperature water bath treatment at 87 ° C, and the electroless plating time is 2 hours; after the electroless plating, take out the steel parts and rinse them with tap water And blow dry, obtain Ni-P amorphous transition layer on the surface of iron and steel parts, and through X-ray diffraction analysis, gained transition layer is amorphous state, and the mass percent content of P in Ni-P amorphous transition layer is 9.1% . The Fe-based amorphous alloy powder is preset on the surface of the Ni-P amorphous transition layer, and the Fe-based amorphous alloy powder is irradiated with a current of 250A, a pulse width of 2.5ms, a pulse fre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com