A low thermal expansion coefficient high modulus glass fiber

A low thermal expansion coefficient and glass fiber technology, applied in the field of glass fiber, can solve the problems of high difficulty in production, low enough expansion coefficient of glass fiber, and failure to meet the requirements of elastic modulus and other mechanical properties at the same time, so as to achieve the improvement of elastic modulus, analysis The effect of low crystallization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

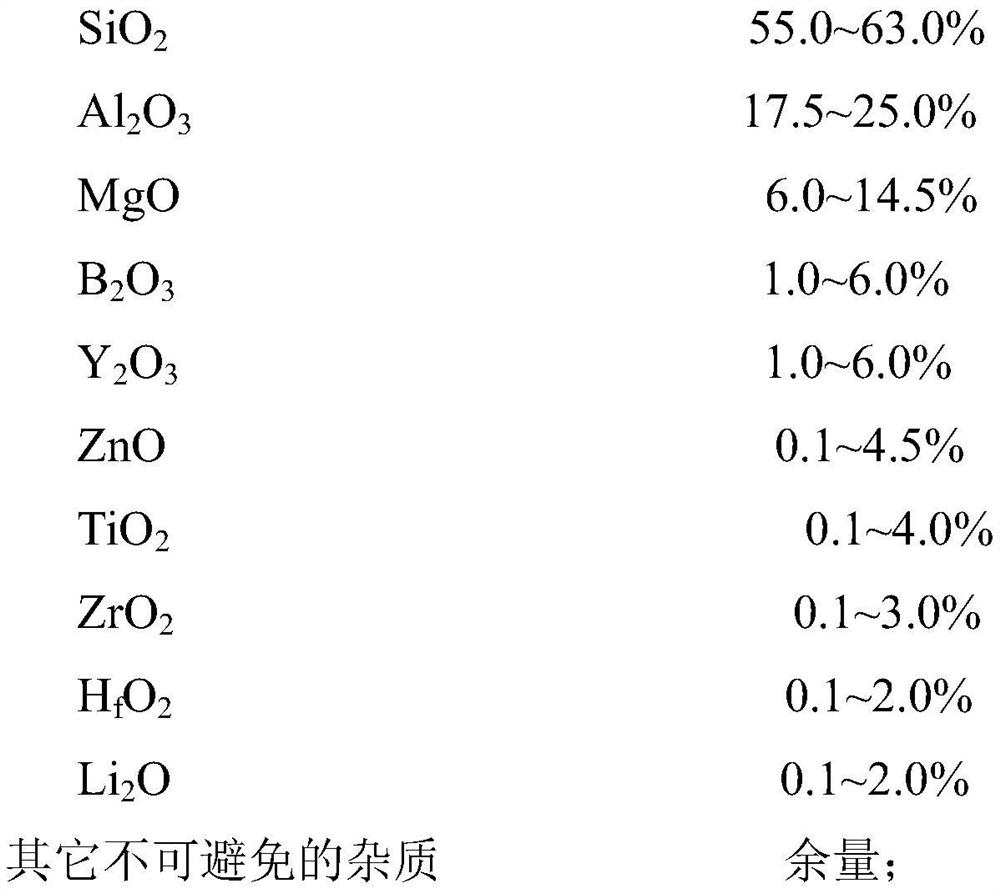

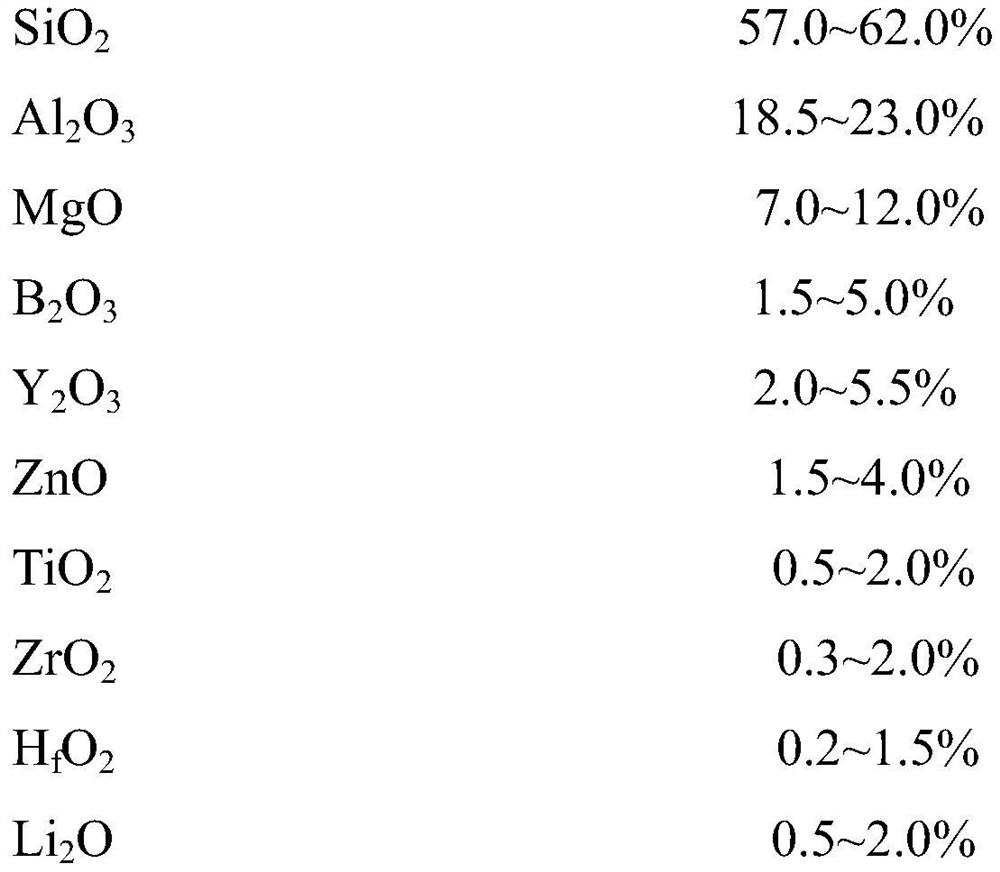

Method used

Image

Examples

Embodiment Construction

[0042] The technical solutions in the embodiments of the present invention will be described below, and the described embodiments are merely embodiments of the invention, not all of the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art are in the range of the present invention without making creative labor premise.

[0043] Production process of low-thermal expansion coefficients high modulus glass fibers, including the following steps:

[0044] (1) According to the implementation formulation, the quality of the raw materials required is calculated, and each raw material is mixed according to the formulation, and the particle grade obtained after homogenization is delivered to the kiln head silo, and then use the feed machine to cooperate. Introduced into the full-electric kiln;

[0045] (2) Mixed ingredients melted and clarified in the full-electric kiln furnace;

[0046] (3) The glass liquid is pu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallization temperature | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com