Oxygen-enriched combustion experiment evaluation device

An experimental device and oxygen-enriched combustion technology, applied in the direction of instruments, teaching models, material thermal development, etc., can solve the problems of high cost and inconvenient operation, and achieve the effect of low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

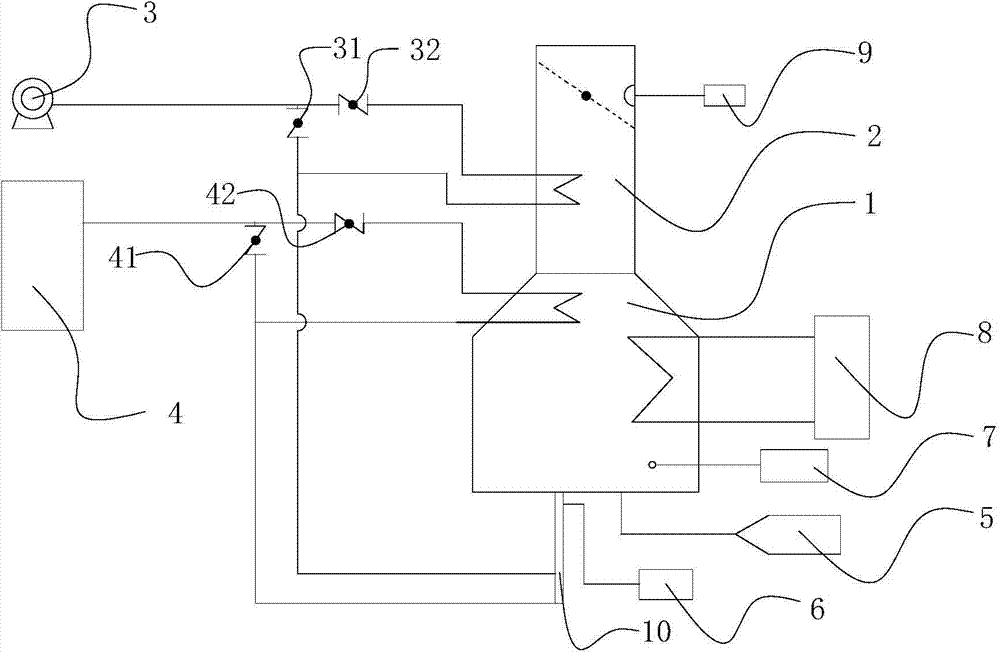

[0018] An oxygen-enriched combustion evaluation experimental device includes a heating furnace 1 and a smoke outlet 2. The heating furnace 1 is equipped with an air inlet pipe 10, and the air inlet pipe 10 is connected to an oxygen-enriched pipeline and an air pipeline. The oxygen-enriched pipeline is connected with an oxygen-enriched generating device 4 ; the air pipeline is connected with a blast device 3 . An oxygen analysis probe connected to an oxygen analyzer 6 is installed on the intake pipe 10 ; the heating furnace 1 is connected to a fuel pipeline, and the fuel pipeline is connected to a fuel supply device 5 . A first flow meter and a flow rate regulator are installed on the fuel pipeline. Through the flow rate regulator, the user can adjust the fuel supply rate. Through the flow meter, the user can calculate the theoretical value of fuel combustion in each period in combination with the unit quantity of fuel heat. total heat generated. A flame temperature detector 7...

Embodiment 2

[0022] On the basis of Example 1, a kind of oxygen-enriched combustion evaluation experimental device can also be that, there is a first damper 31 on the oxygen-enriched pipeline, and the first damper 31 is connected with an oxygen-enriched heating tube in parallel, and the oxygen-enriched heating tube A second damper 32 is installed on the top, and the oxygen-enriched heating pipe extends into the chimney 2; a third damper 41 is provided on the air pipeline, and an air heating pipe is connected in parallel with the third damper 41, and the air heating pipe is installed There is a fourth damper 42, and the air heating pipe extends into and out of the chimney 2.

[0023] The oxygen-enriched pipeline is connected in parallel with an oxygen-enriched heating pipe extending into and out of the chimney 2, and the air pipeline is connected in parallel with an air heating pipe extending into and out of the chimney 2, and the user can close the first damper 31 or the third damper 41, O...

Embodiment 3

[0025] On the basis of embodiment 1 or embodiment 2, a kind of oxygen-enriched combustion evaluation experimental device can also be, also comprise server, display screen is installed on the server, described server is connected with temperature detector, oxygen analyzer, flame temperature respectively. The detector 7, the flue gas analyzer 9, the first flowmeter, and the second flowmeter are connected. The server also includes a control mechanism, which is connected to the flow rate regulator, the blast device 3, the oxygen-enriched generator 4, the first damper 31, the second damper 32, the third damper 41, the fourth damper 42, and the flow rate Regulator. The control mechanism is connected with each component, which can play the role of control and adjustment, and facilitates the operation of each component by the user.

[0026] The oxygen-enriched combustion evaluation experimental device includes a server, and the user can conveniently obtain the experimental parameters...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com