Emergency control system and method for substation charged water flushing robot

An emergency control and control system technology, applied in general control systems, control/regulation systems, computer control, etc., can solve the problems of poor pure water preparation capacity, high labor intensity, and inability to wash away dirt, so as to improve automation and The level of intelligence, the reduction of heavy physical labor, and the effect of preventing equipment pollution flashover accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0035] The substation live water washing water washing robot includes a robot body and a robot control system.

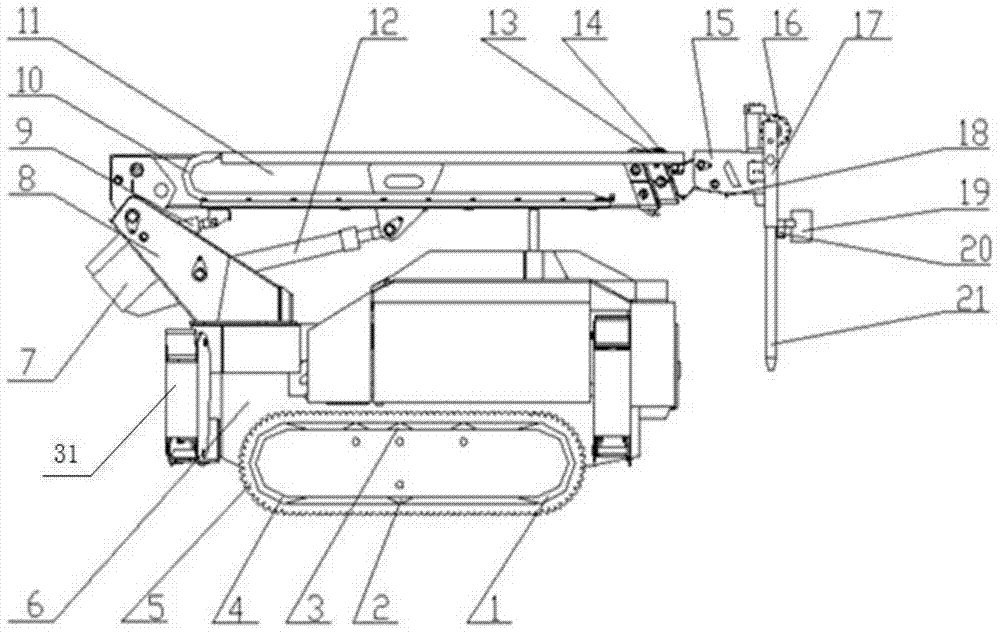

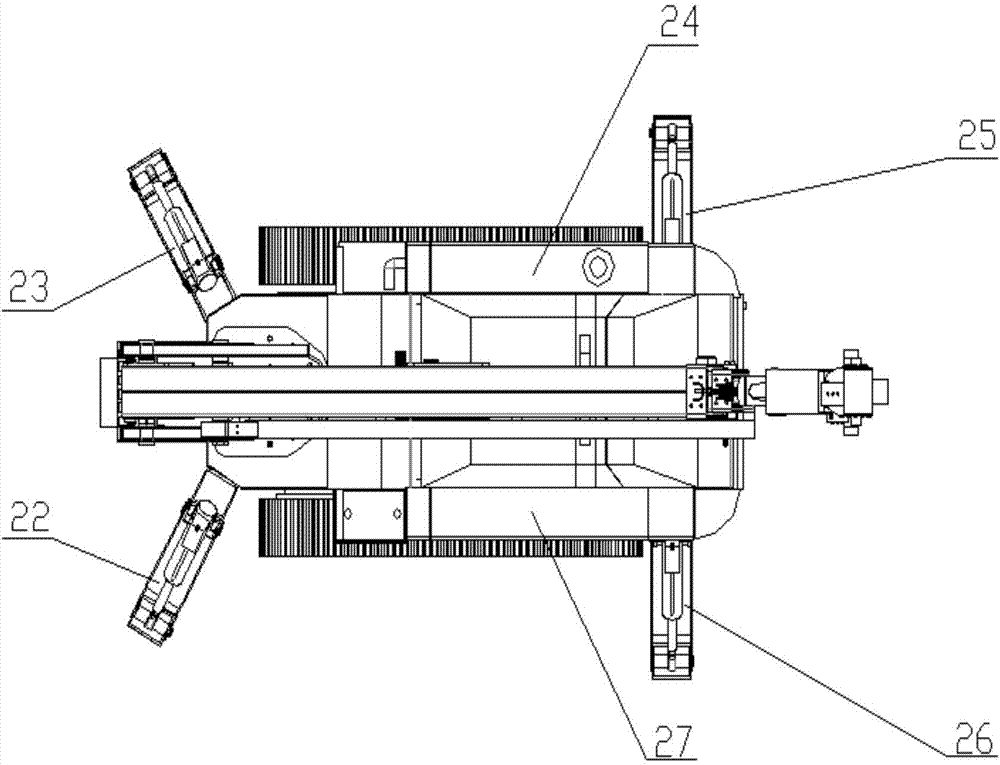

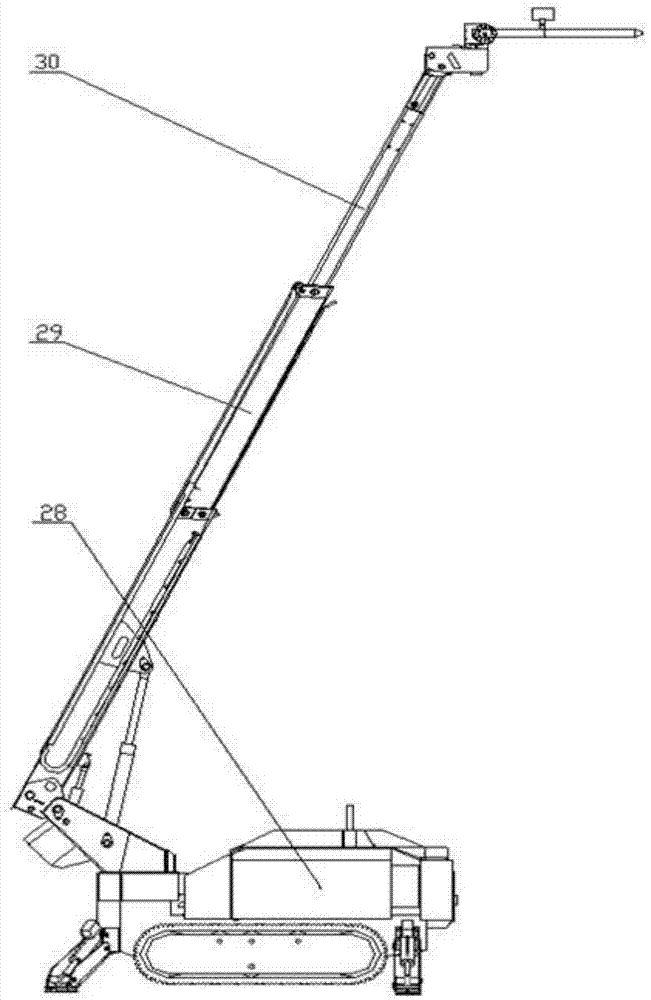

[0036] The schematic diagram of the structure of the charged water washing robot is as follows: Figure 1-Figure 3As shown, the main body is composed of a mechanical body and a remote control device. Among them, the mechanical body is mainly composed of a car body moving mechanism, a three-section two-stage telescopic arm lifting mechanism, a water gun flushing mechanism, a hydraulic control system and an electrical control system. The car body moving mechanism is a crawler-type mobile chassis structure, one side of the crawler chassis is a diesel tank, the other side is a hydraulic oil tank, and the power source of the robot is a vehicle-mounted diesel engine; the car body moving mechanism is connected to the slewing platform 8 of the lifti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com