A double-layer coil for electromagnetic forming and its manufacturing method

An electromagnetic forming and coil technology, applied in the direction of coil manufacturing, coil, circuit, etc., can solve the problems of high resistance of welding joints, influence of overall strength of coil, reduction of winding density and number of turns, etc., to improve insulation and strength, and reduce inner wall. Interference, the effect of increasing the number of coil turns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

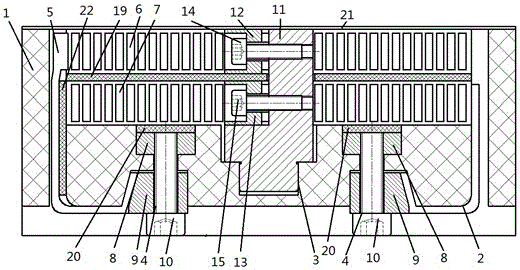

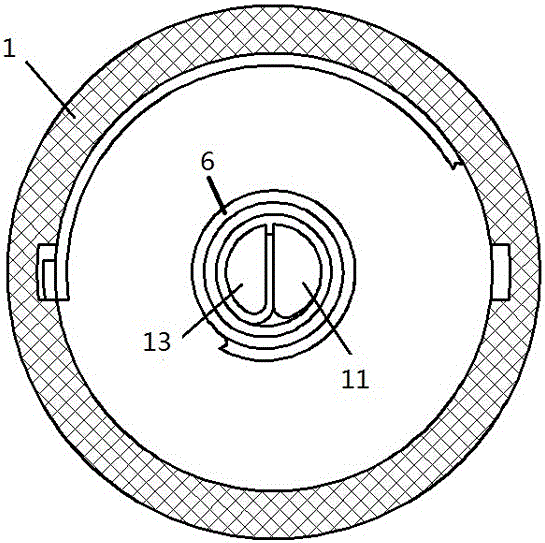

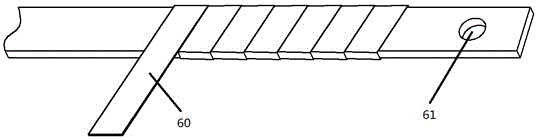

[0032] Such as Figure 1~5 As shown, the embodiment of the present invention provides a double-layer coil for electromagnetic forming, which includes a cylindrical shell 1, and the front of the shell 1 is provided with a circular groove 2 for placing the coil. An upper layer coil 6 and a lower layer coil 7 are sequentially arranged in the groove 2 from top to bottom, a rectangular through hole 5 is provided in the groove 2 close to the edge of the housing 1, and the middle part of the groove 2 is provided with There is a stepped blind hole 3 for placing an intermediate joint, the intermediate joint is matched with the stepped blind hole 3, and a rectangular first blind hole 4 is symmetrically provided on both sides of the stepped blind hole 3; The back of the housing 1 is provided with a second blind hole corresponding to the first blind hole 4, and the second blind hole is provided with an inclined side, and the first blind hole 4 and the second blind hole pass through a The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com