led testing process and correction method for this

A technology of testing process and correction function, which is applied in the direction of photometry, semiconductor/solid-state device testing/measurement, measuring device, etc., and can solve problems that are not suitable for high-capacity testing applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

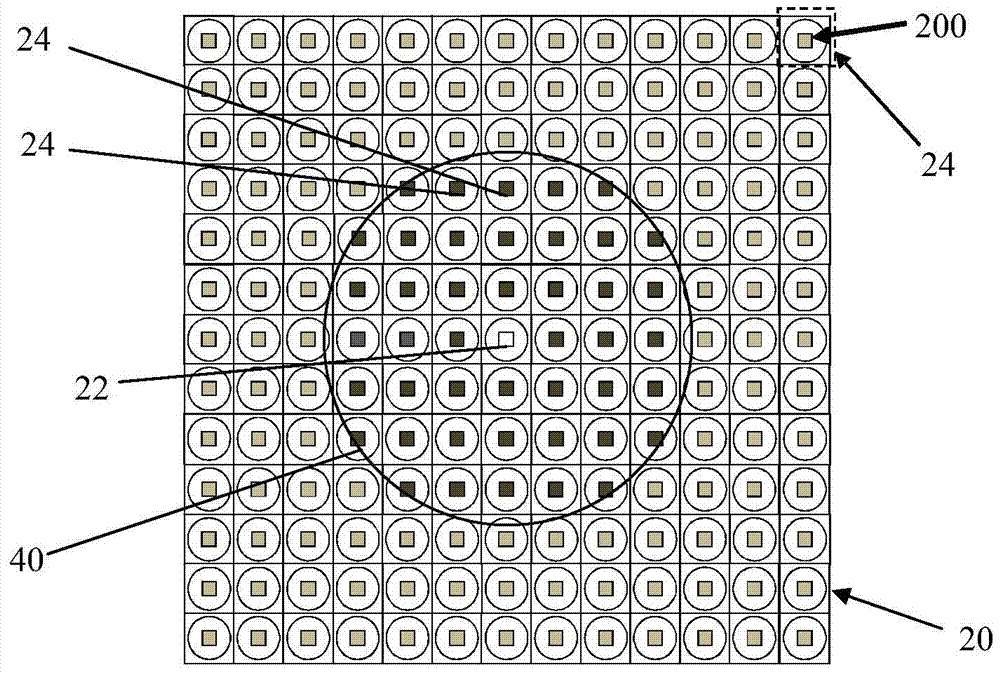

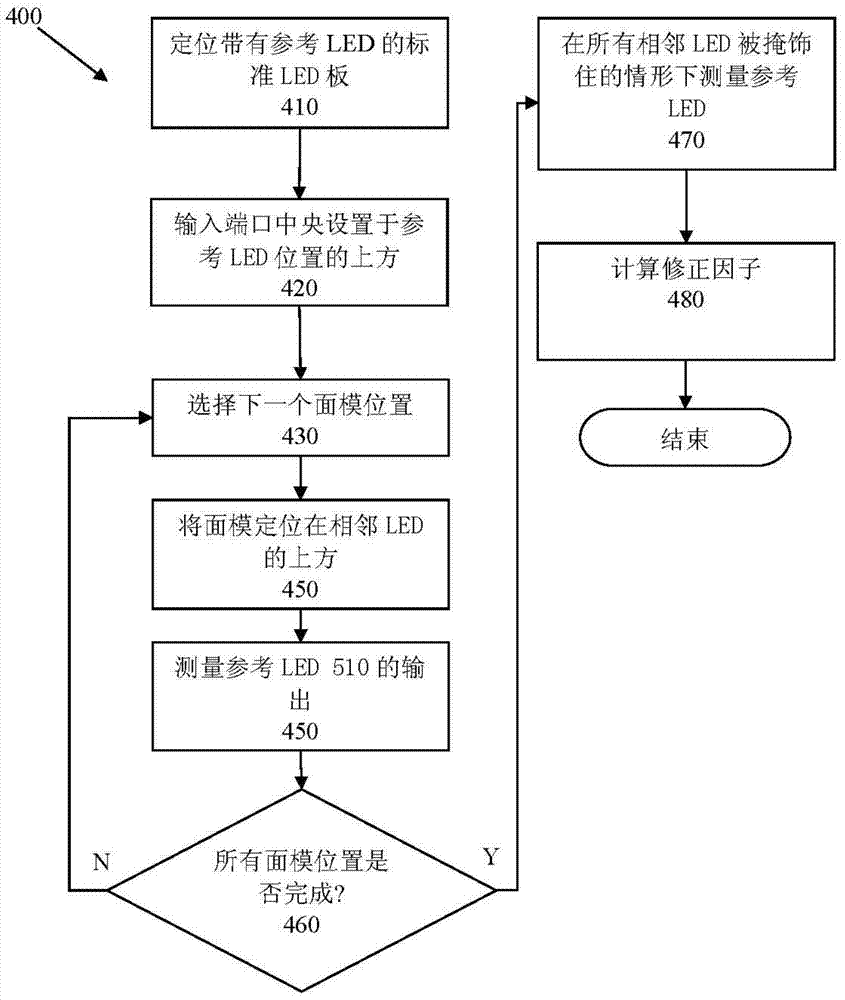

[0044] Embodiments of the present invention provide a method for directly testing an array of LED units on a substrate without first requiring dicing. Profiles of test results containing measured optical and electrical properties as a function of position in the array can be generated and used to bin LEDs prior to dicing and packaging. This method has a higher throughput than previously known methods because less cell sorting processing is required. The risk of damage or contamination is also reduced due to the reduced overall sorting volume.

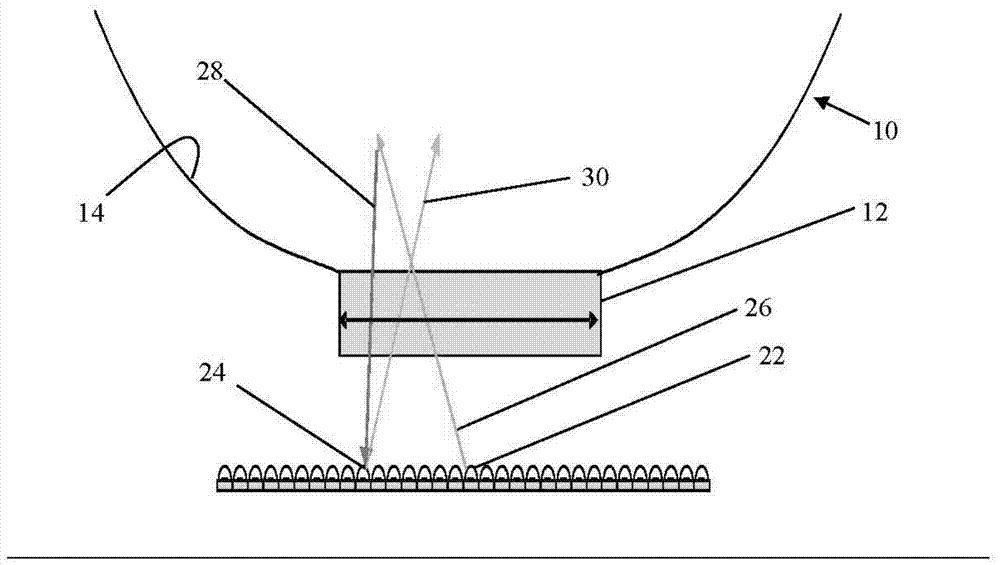

[0045]The inventors of the present invention have realized for the first time that LEDs can be tested in-panel at high throughput by substantially modifying the light re-emitted from the phosphors of those LEDs that are not activated adjacent to the DUT. The re-lit puzzle set forth in figure 1 , wherein a detector device comprising an integrated ball 10 with an input port 12 is placed above the LED 22 (DUT), which is activated and emi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com