Polyamide-based water-treatment separation membrane having excellent salt removal rate and permeation flux characteristics, and method for manufacturing same

A technology for water treatment and separation membranes, applied in chemical instruments and methods, semi-permeable membrane separation, membranes, etc., to solve problems such as membrane permeation flux decline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

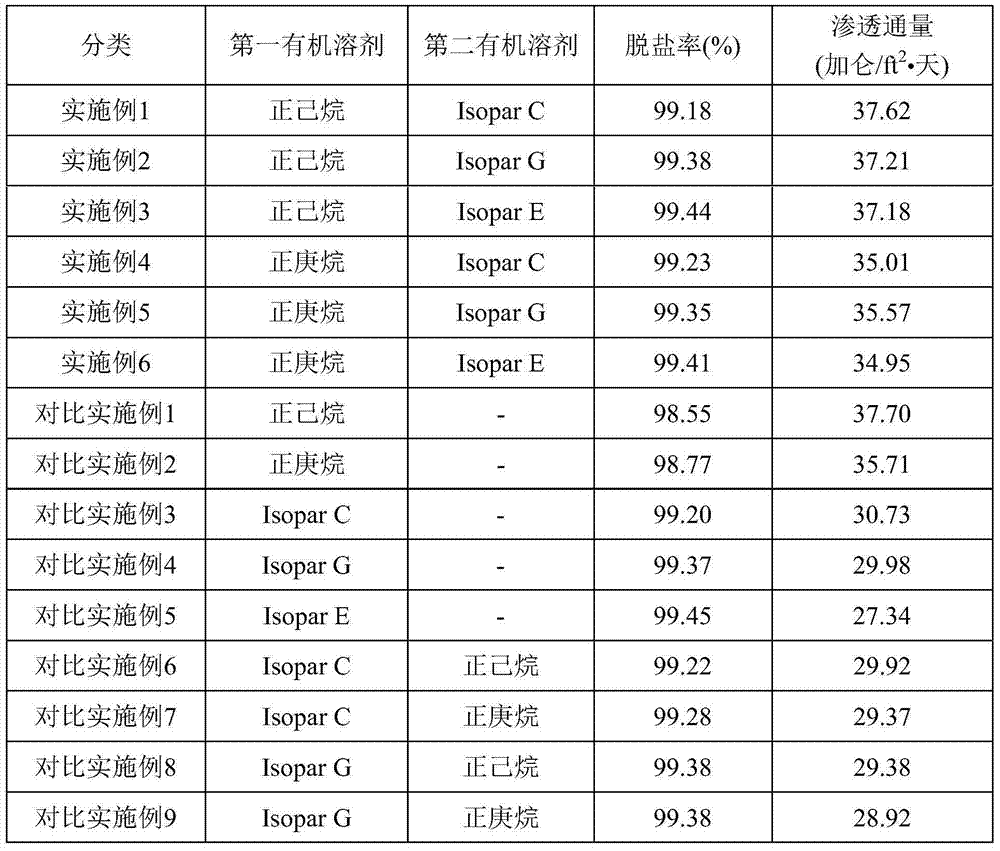

Examples

Embodiment 1

[0061] 18% by weight polysulfone solid was added into a DMF (N,N-dimethylformamide) solution and dissolved therein at a temperature of 80° C. to 85° C. for more than 12 hours to obtain a uniform liquid phase. The solution with a homogeneous liquid phase was cast on a nonwoven fabric formed of polyester material with a thickness of 95 to 100 μm, to a thickness of 45 to 50 μm. Then, the cast nonwoven fabric was placed in water to form a porous polysulfone support.

[0062] After the porous polysulfone support prepared by the above method was immersed in an aqueous solution containing 2% by weight of m-phenylenediamine, 1% by weight of triethylamine, and 2.3% by weight of camphorsulfonic acid for 2 minutes and taken out, a pressure of 25 psi was used to The lower roller removes excess aqueous solution on the support, and then the porous polysulfone support is dried at room temperature for 1 minute.

[0063] After that, an organic solution containing n-hexane (manufactured by Sig...

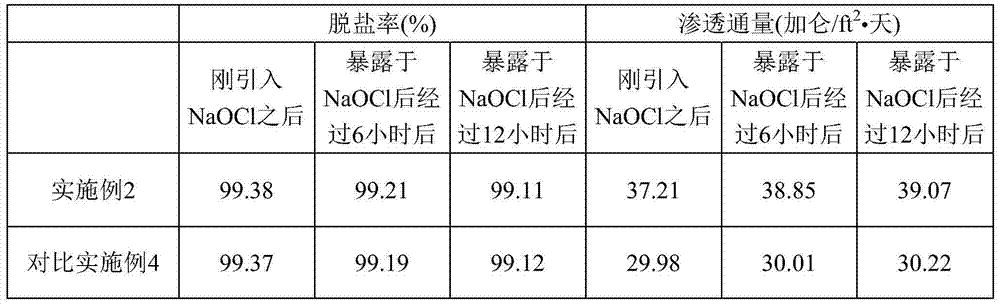

Embodiment 2

[0066] A water treatment separation membrane was prepared using the same method as in Example 1, except that Isopar G was used as the second organic solvent.

Embodiment 3

[0068] A water treatment separation membrane was prepared using the same method as in Example 1, except that Isopar E was used as the second organic solvent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| salt rejection rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com