Low-elastic-modulus integrated titanium-based femoral handle and preparation method thereof

A technology of low elastic modulus and femoral stem, which is applied in the research field of artificial joints in medical devices. It can solve the problems of complex manufacturing process and inability to complete the preparation at one time, and achieve uniform distribution of pores, relieve stress shielding problems, and ensure strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

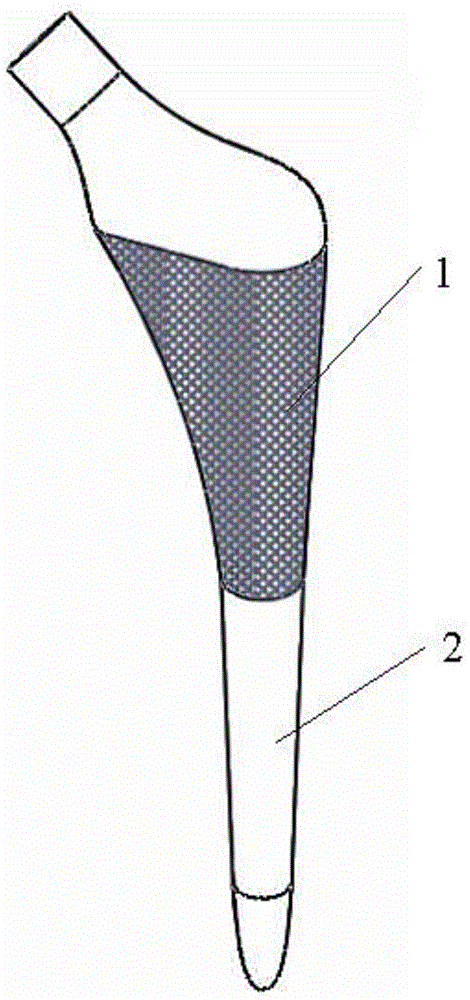

[0037] Such as figure 1 As shown, the low elastic modulus integrated titanium-based femoral stem involved in this embodiment includes two parts, the first part is the porous scaffold structure 1, the second part is the femoral stem body 2, and the porous scaffold structure 1 is coated on the femoral stem The neck of the main body 2 is connected with human bone tissue, and the pores are evenly distributed, and the pores are equal in size from the outside to the inside, and the size of the pores ranges from 100 μm to 1 mm.

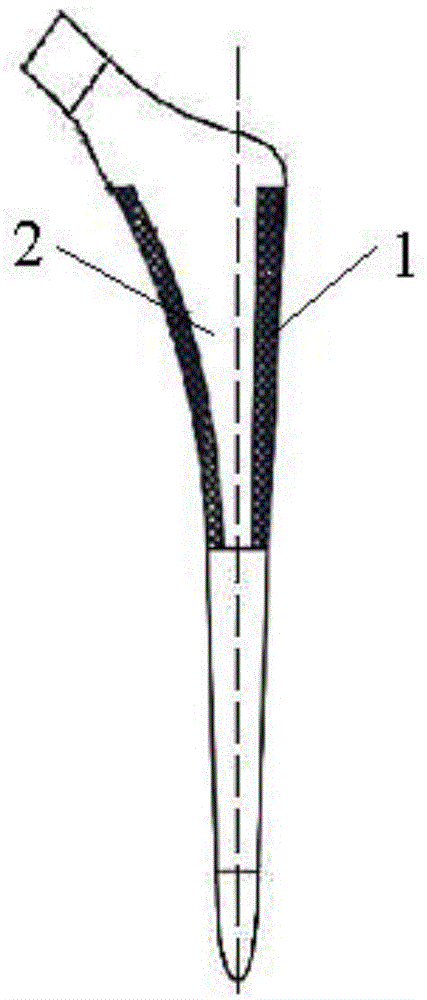

[0038] Such as figure 2 , image 3As shown, the depth range of the porous scaffold structure 1 is 40%-60% of the depth of the femoral cross section from outside to inside, and the rest of the femoral stem is the femoral stem body 2 .

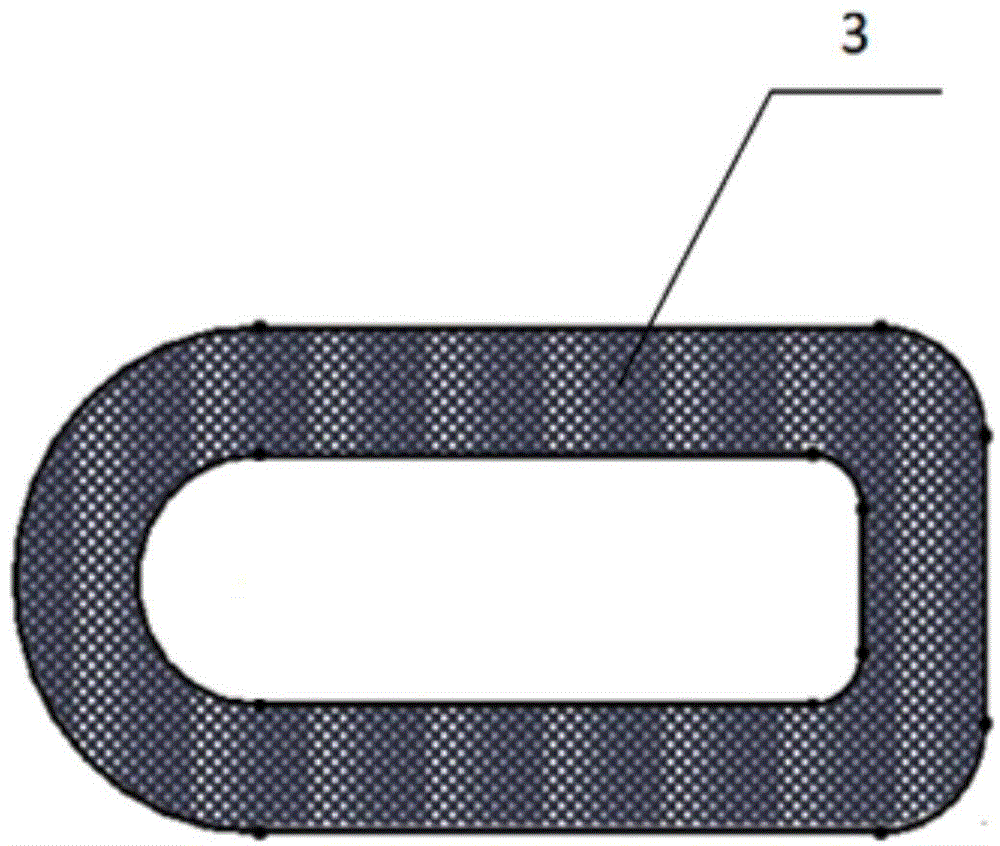

[0039] The porous scaffold structure 1 is modeled on the cancellous bone structure of the human body, and is composed of many porous structural units 3, and the structure of each porous structural unit 3 is as follows Fig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com