A kind of preparation method of fly ash/graphene oxide composite adsorption material

A graphene composite and adsorption material technology, applied in chemical instruments and methods, other chemical processes, etc., can solve problems such as difficulty in separation, and achieve the effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

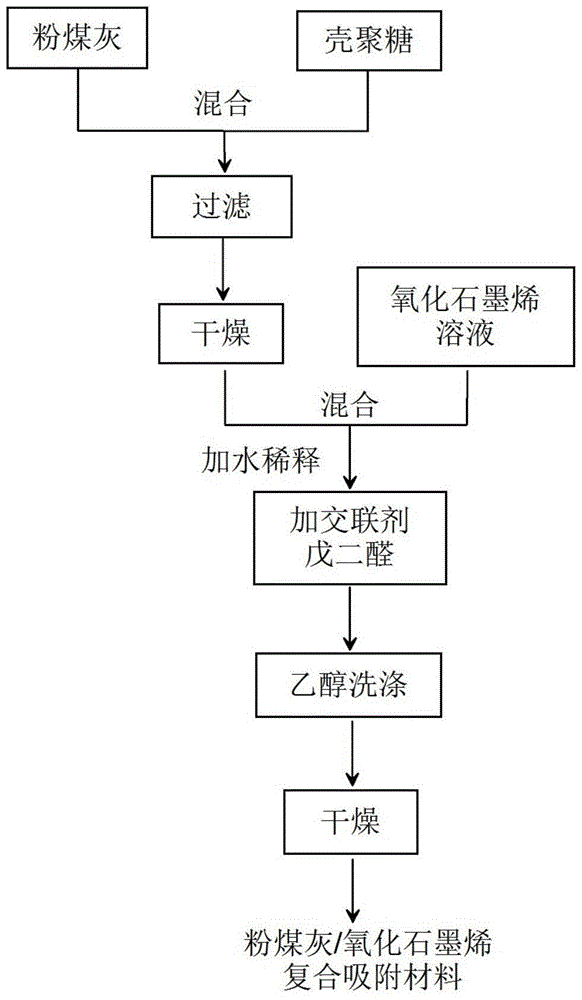

Method used

Image

Examples

Embodiment 1

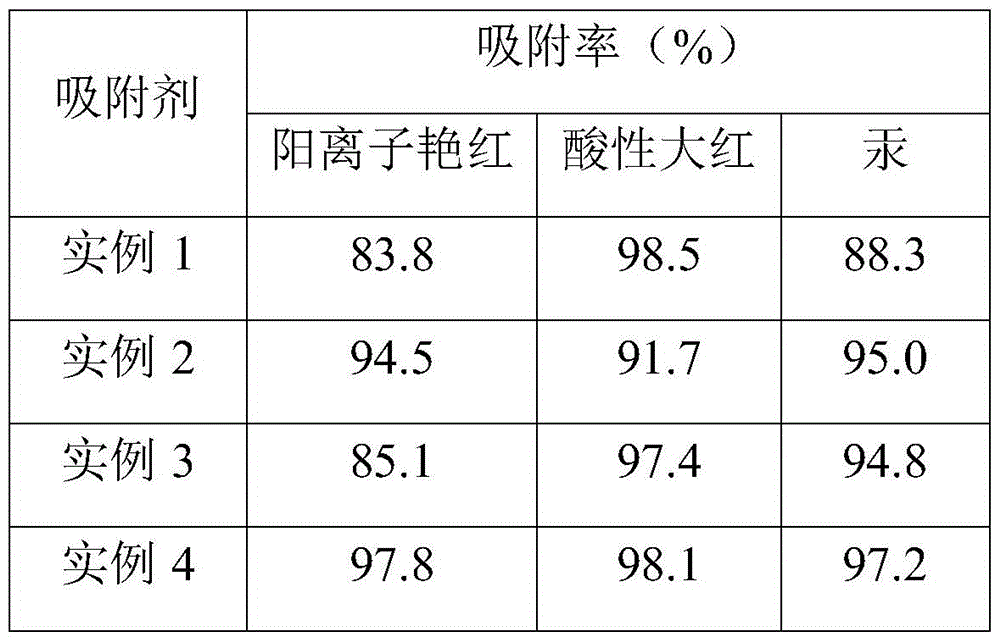

[0018] When preparing, take 1g of fly ash, add 1mL of chitosan solution with a mass concentration of 5% and soak for 2h, then filter and dry at 50°C for 3h, then add it to 10mL of 5g / L graphene oxide solution and soak for 12h, while stirring for 2h , dilute with water until the solid phase concentration reaches 40g / L, add 2mL glutaraldehyde for cross-linking for 3h, the cross-linking temperature is 80°C, filter off the liquid phase and wash with absolute ethanol until neutral, then vacuum dry at 60°C for 6h to obtain a compound Adsorbent material.

Embodiment 2

[0020] When preparing, take 1g of fly ash, add 1mL of chitosan solution with a mass concentration of 1% for immersion for 3h, then filter and dry at 80°C for 2h, then add 15mL of 5g / L graphene oxide solution for immersion for 10h, stir for 3h at the same time, add water When diluting to a solid phase concentration of 40g / L, add 1mL glutaraldehyde for cross-linking for 3h, the cross-linking temperature is 80°C, filter off the liquid phase and wash with absolute ethanol until neutral, then vacuum dry at 60°C for 5h to obtain a composite adsorption material .

Embodiment 3

[0022] When preparing, take 1g of fly ash, add 1mL of chitosan solution with a mass concentration of 2.5% and soak for 3h, then filter and dry at 80°C for 2h, then add 20mL of 2g / L graphene oxide solution for soaking for 8h, stir for 3h at the same time, add water When diluting to a solid phase concentration of 40g / L, add 0.5mL glutaraldehyde for crosslinking for 2h, the crosslinking temperature is 80°C, filter off the liquid phase and wash with absolute ethanol until neutral, then vacuum dry at 60°C for 6h to obtain the composite adsorption Material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com