Preparation method of polyethyleneimine modified chitosan magnetic composite material

A technology of polyethyleneimine and chitosan, applied in chemical instruments and methods, alkali metal compounds, alkali metal oxides/hydroxides, etc. It is used to remove pollutants and other problems to achieve the effects of low cost, good heavy metal adsorption performance, and good separation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

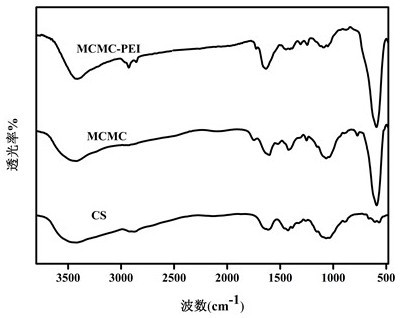

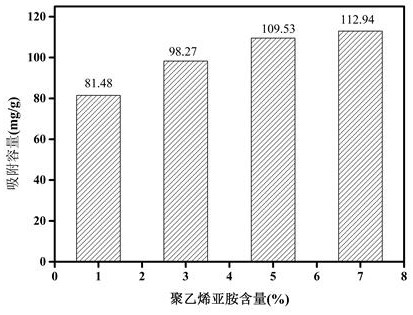

[0045] Weigh 0.5 g of the above magnetic carboxymethyl chitosan and disperse it in 50 mL of distilled water, adjust the pH value to 4, add 0.2-0.4 g of EDC and 0.15-0.25 g of NHS to activate at room temperature for 0.5 h, then add 20 mL of 1 % polyethyleneimine solution, and adjust the pH value to 5, and react at room temperature for 24 hours. After the reaction is completed, it is magnetically separated, washed with distilled water and ethanol for several times, and then dried in a vacuum oven to obtain MCMC-PEI-1.

Embodiment 2

[0047] Weigh 0.5 g of the above-mentioned magnetic carboxymethyl chitosan and disperse it in 50 mL of distilled water, adjust the pH value to 4, add 0.2-0.4 g of EDC and 0.15-0.25 g of NHS to activate at room temperature for 0.5 h, then add 20 mL of 3% polyethyleneimine solution, adjust the pH value to 5, and react at room temperature for 24 hours. After the reaction is completed, it is magnetically separated, washed with distilled water and ethanol for several times, and then dried in a vacuum oven to obtain MCMC-PEI-2 .

Embodiment 3

[0049] Weigh 0.5 g of the above magnetic carboxymethyl chitosan and disperse it in 50 mL of distilled water, adjust the pH value to 4, add 0.2-0.4 g of EDC and 0.15-0.25 g of NHS to activate at room temperature for 0.5 h, then add 20 mL of 5 % polyethyleneimine solution, adjust the pH value to 5, and react at room temperature for 24 hours. After the reaction is completed, it is magnetically separated, washed with distilled water and ethanol several times, and then dried in a vacuum oven to obtain MCMC-PEI-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com