Method for optimizing tension system for rolling of ultra thin steel strip of cold continuous rolling mill

A technology of cold tandem rolling unit and optimization method, which is applied in the direction of tension/pressure control, etc., and can solve problems such as distribution of stress peaks between rolls, increase in roll consumption, and product degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

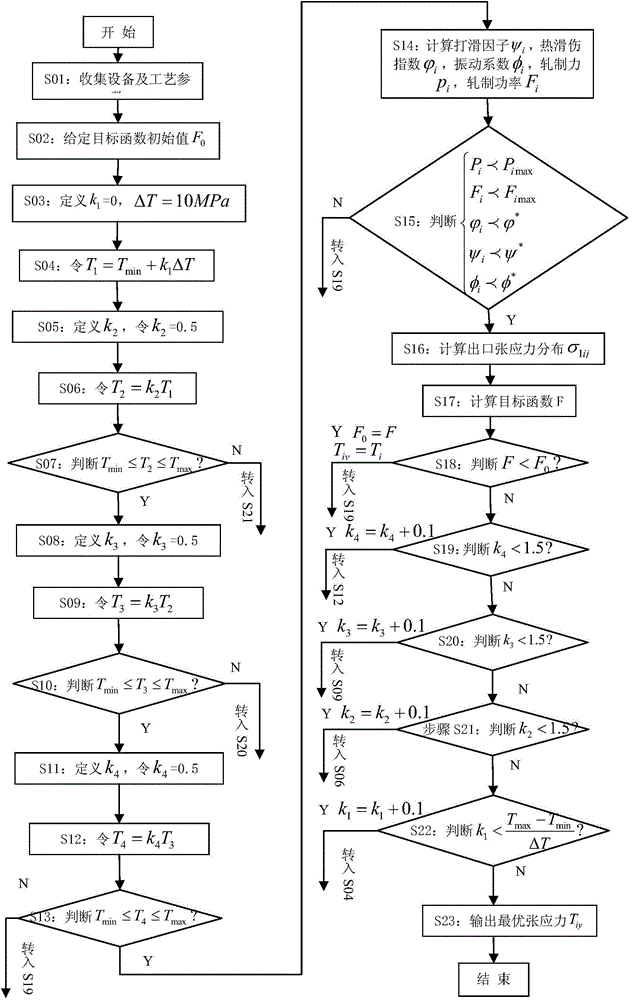

[0041] figure 1 It is an embodiment of the tension system optimization method for ultra-thin strip rolling in the cold tandem mill of the present invention. In order to further illustrate the application process of the related technology described in the present invention, this embodiment uses 1420 five-stand 3+2 type CVC Taking the tandem cold rolling mill as an example, it introduces in detail the setting process of the tension system optimization method in the ultra-thin strip rolling process of a 3+2 type CVC tandem cold rolling mill. exist figure 1 In the shown control flowchart, the tension system optimization method of the present invention comprises the following steps:

[0042] In step S01, key equipment parameters and process parameters of the cold tandem rolling mill are obtained, including the following steps:

[0043] a1) Collect equipment parameters of 3+2 type CVC tandem cold rolling mill, including:

[0044] 1-5# frame work roll diameter D wi ={482.89,486.3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com