Petroleum pipeline machining equipment

A technology for oil pipelines and processing equipment, applied in metal processing equipment, shearing machine equipment, pipe cutting devices, etc., can solve the problems of affecting the sealing effect, uneven cutting, low efficiency, etc., to ensure the cutting effect and deepen the cutting thickness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

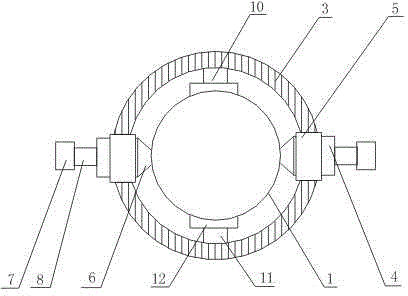

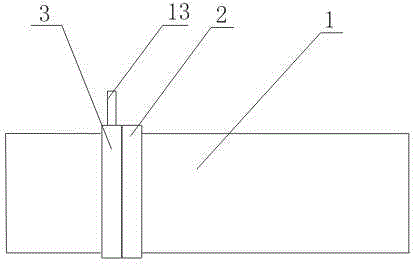

[0018] like figure 1 , figure 2 , Figure 4 As shown, an oil pipeline processing equipment includes a hoop 2 sleeved on an oil pipeline 1, a ring hole 14 is opened on the side of the hoop 2, a cutting ring 3, and a cutting ring fixed on one side of the cutting ring 3 are also included. Ring 3 concentric circular ring 15 and cutter 4 fixed on the other side of cutting ring 3, circular ring 15 is rotatably arranged in circular ring hole 14; Cutter 4 comprises cutting seat 5, cutting knife 6, and cutting seat 5 is The cavity structure with both ends open, the cutting knife 6 slides through the cutting seat 5 and is set in the cutting seat 5; it also includes a hydraulic cylinder 7 fixed on the cutting knife 6, and the piston rod 8 in the hydraulic cylinder 7 is connected to the position where the cutting knife 6 is located. Cut ring 3 on the outer end.

[0019] In this embodiment, let the hoop 2 be firmly sleeved on the oil pipeline 1 first, and the cutting ring 3 is rotated ...

Embodiment 2

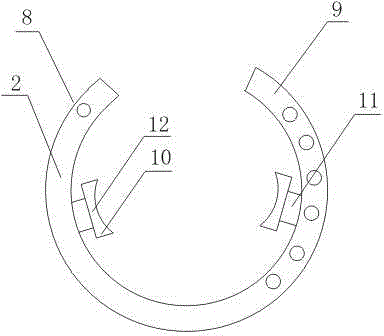

[0021] This embodiment is on the basis of embodiment 1, as image 3 As shown, the hoop 2 includes a steel strip 9, the rear end of the steel strip 9 is a cavity with an open end, the left side of the front end of the steel strip 9 is provided with a threaded counterbore, and the left side of the rear end of the steel strip 9 is evenly opened There is a through hole communicating with the cavity, the front end of the steel strip 9 is inserted into the cavity at the rear end of the steel strip 9 and fixed by a bolt that passes through the through hole and is threadedly connected with the threaded counterbore; the circular hole 14 is arranged on the steel strip 9 to the right of the .

[0022] In this embodiment, the hoop 2 can be firmly fixed on the oil pipeline 1 only by passing the bolts through the holes at both ends of the steel strip 9 at the same time. The other end of the steel belt 9 is provided with even holes on the circumference surface so that the size of the hoop 2...

Embodiment 3

[0024] This embodiment is on the basis of embodiment 1 or embodiment 2, as image 3 As shown, it also includes a deck 10 arranged on the inner surface of the hoop 2; the deck 10 includes a base 11, a draw-in groove 12 fixed on the base 11, the front end of the draw-in slot 12 is an arc structure, and the base 11 is fixed on the embrace on the inner surface of hoop 2.

[0025] In this embodiment, the front end of the clamping groove 12 has an arc-shaped structure, so that the hoop 2 can be sleeved on the oil pipeline 1 more stably.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com