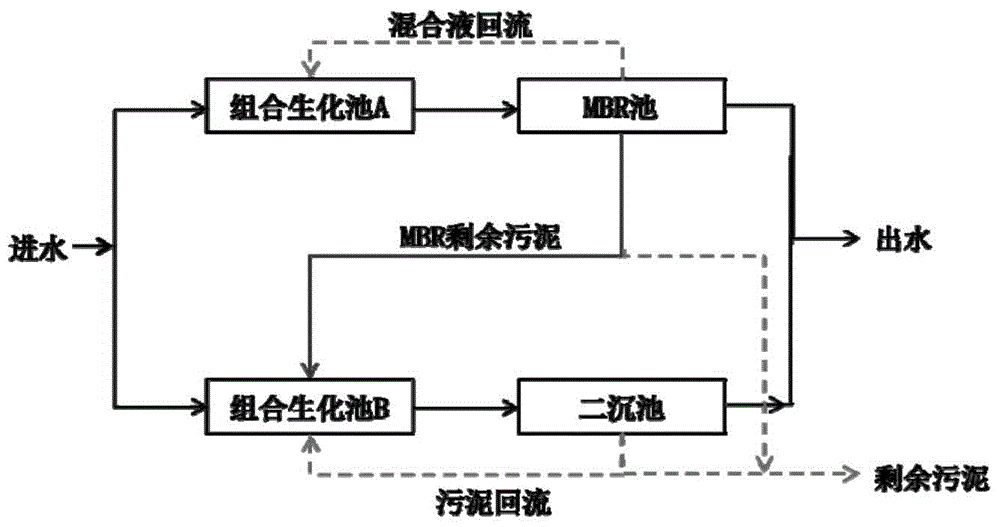

Combined cas‑mbr sewage treatment system

A sewage treatment system and composite technology, applied in the field of composite CAS-MBR sewage treatment system, to achieve the effect of reducing the amount of excess sludge, high activity and preventing sludge expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

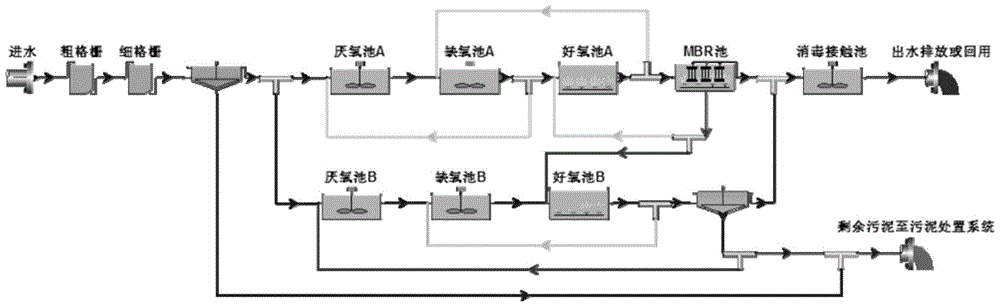

[0052] The first phase process of a sewage treatment plant in the north is the traditional "AAO + secondary sedimentation tank", and the effluent water quality is in accordance with the "Pollutant Discharge Standards for Urban Sewage Treatment Plants" (GB18918-2002) Class A A implementation. After passing through the pretreatment system (including coarse screen, fine screen and primary sedimentation tank), the sewage enters the combined biochemical tank (anaerobic tank-anoxic tank-aerobic tank), and finally passes through the secondary sedimentation tank. The treatment scale of the system is 100,000 m 3 / d.

[0053] A new MBR process was built in the second phase of the sewage treatment plant, with a treatment scale of 200,000 m 3 / d, realize expansion, and upgrade the first-phase process. like figure 2 As shown, the first sub-system is the second-phase project, and the second sub-system is the original first-phase project; an MBR pool is installed downstream of the combin...

Embodiment 2

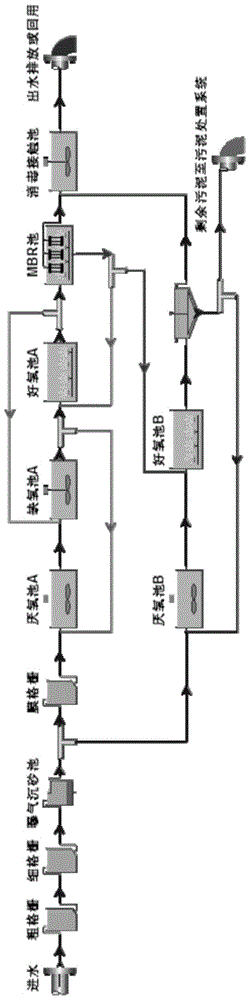

[0069] The main process of the first phase of a sewage treatment plant in central China is the traditional "AO + secondary sedimentation tank", and the effluent water quality is in accordance with the "Pollutant Discharge Standards for Urban Sewage Treatment Plants" (GB18918-2002) Grade B. After passing through the pretreatment system (including coarse screen, fine screen and aerated grit chamber), the sewage enters the combined biochemical tank (anaerobic tank-aerobic tank), and finally passes through the secondary sedimentation tank. The system has a treatment scale of 55,000 m 3 / d.

[0070] A new MBR process was built in the second phase of the sewage treatment plant, with a treatment scale of 110,000 m 3 / d, realize expansion, and upgrade the first-phase process. like image 3As shown, the first sub-system is the second-phase project, and the second sub-system is the original first-phase project; an MBR pool is installed downstream of the combined biochemical pool of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com