Multifunctional environment-friendly polyurethane composite material and preparation method thereof

A polyurethane and polyurethane technology, which is applied in the field of multifunctional and environmentally friendly polyurethane composite materials and their preparation, achieves the effects of light weight, good wear resistance and good slip resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] In this embodiment, the multifunctional environment-friendly polyurethane composite material of the present invention includes thermoplastic polyurethane polymers, environment-friendly additives, and viscosity-enhancing and dispersing agents.

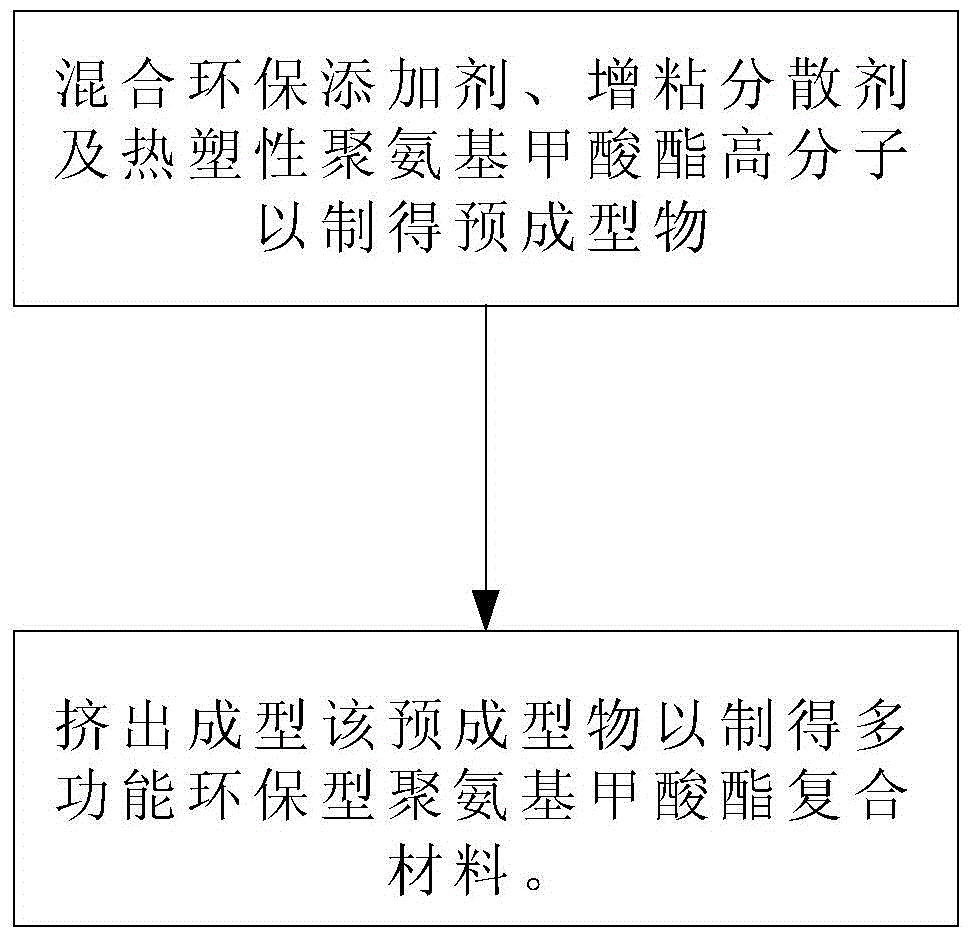

[0057] see figure 1 As shown, in the present embodiment, the preparation method of the multifunctional environment-friendly polyurethane composite material, the steps include:

[0058] Mix the environmental protection additive, the viscosifying dispersant and the thermoplastic polyurethane polymer to make a preform: with a stirring blender, the operating temperature is 25 ° C, the screw speed is 150 revolutions per minute (rpm ) and the stirring time is 1 hour (hr) to mix the environmental protection additive and the thickening and dispersing agent to obtain the primary mixture; then use the stirring blender at an operating temperature of 60°C and a screw speed of 150 rpm ( rpm) and a stirring time of 1 hour (hr), mixing the the...

Embodiment 2

[0065] This embodiment is substantially the same as Embodiment 1.

[0066] Only in this embodiment, in the step of mixing the environmental protection additive, the thickening dispersant and the thermoplastic polyurethane polymer to prepare the preform, the stirring and blending machine is operated at a temperature of 60°C Under the conditions, the thermoplastic polyurethane polymer is mixed with the primary mixture to obtain the preform; in the step of extruding the preform to obtain a multifunctional environment-friendly polyurethane composite material , the extrusion molding machine heat-melts and extrudes the preform under the conditions of a hot-melt temperature of 200°C and a screw speed of 90 rpm to obtain the multi-functional environmentally friendly polyurethane composite material . Among them, the thermoplastic polyurethane polymer is T195M of Sanhuang Co., Ltd., its hardness is 95A, its melt index is 7.164g / 10min, the environmental protection additive is recycled t...

Embodiment 3

[0071] This embodiment is substantially the same as Embodiment 1.

[0072] Only in this embodiment, in the step of mixing the environmental protection additive, the thickening dispersant and the thermoplastic polyurethane polymer to prepare the preform, the stirring and blending machine is operated at a temperature of 60°C Under the conditions, the thermoplastic polyurethane polymer is mixed with the primary mixture to obtain the preform; in the step of extruding the preform to obtain a multifunctional environment-friendly polyurethane composite material , the extrusion molding machine heat-melts and extrudes the preform under the conditions of a hot-melt temperature of 200°C and a screw speed of 90 rpm to obtain the multi-functional environmentally friendly polyurethane composite material . Among them, the thermoplastic polyurethane polymer is T975LM2 of Sanhuang Co., Ltd., its hardness is 75A, and its melt index is 7.164g / 10min; the viscosity-increasing dispersant is butadi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com