Bio-enzyme gel breaker, and applications thereof

A technology of gel breaker and biological enzyme, which is applied in the direction of drilling compositions, chemical instruments and methods, etc., and can solve the problems that water-based gel fracturing fluid cannot be effectively broken quickly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

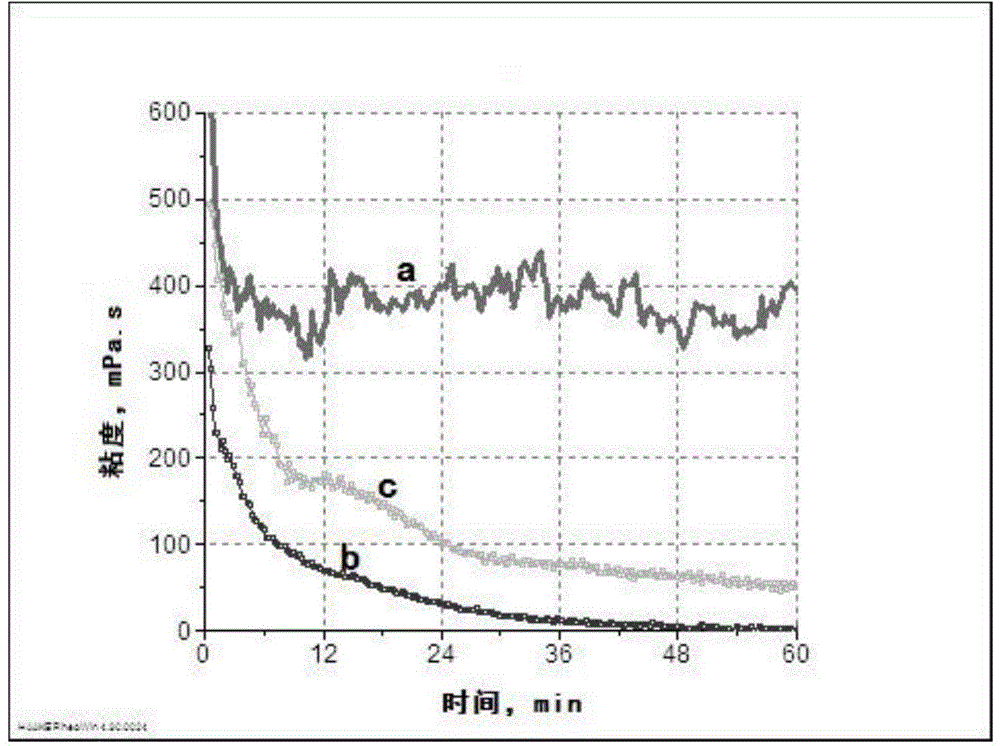

Embodiment 1

[0025] Fracturing fluid base fluid formula: potassium chloride 2.0%, coumarin 0.3%, demulsifier 0.1%, drainage aid 0.1%. Prepare fracturing fluid base fluid according to the above formula, swell for more than 4 hours, and use it for later use.

[0026] 1) Prepare 1.0% borax decahydrate solution as the fracturing fluid cross-linking agent, and add β-mannanase and α-galactosidase to the cross-linking agent liquid to make the final concentration reach 200U / mL and 100U / mL.

[0027] 2) Prepare 1.0% borax decahydrate solution as the fracturing fluid cross-linking agent, and add β-mannanase and α-galactosidase to the cross-linking agent liquid to make the final concentration reach 80 U / mL and 40U / mL.

[0028] Take the above-mentioned crosslinking agent added with gel breaker, and prepare 100mL fracturing fluid with a crosslinking ratio (volume ratio) of 100:5, and 170s at 20℃ -1 Shear for 60 minutes and record the fracturing fluid viscosity-temperature curve, such as figure 1 Shown.

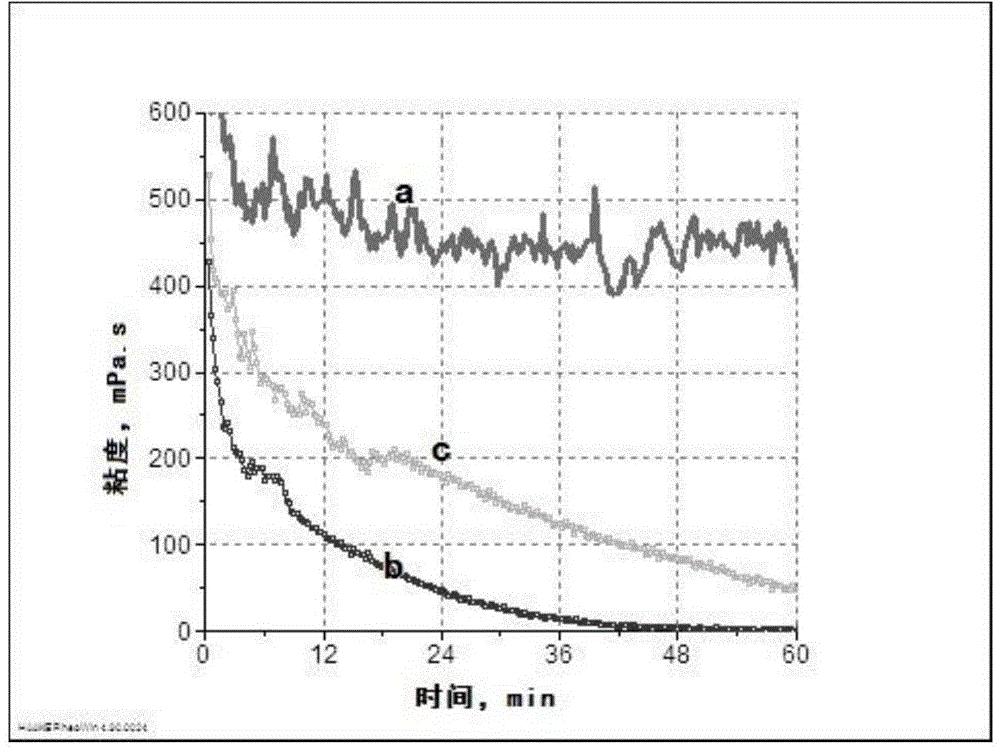

Embodiment 2

[0034] Formula of fracturing fluid base fluid: potassium chloride 2.0%, coumadin 0.35%, demulsifier 0.1%, drainage aid 0.1%. Prepare fracturing fluid base fluid according to the above formula, swell for more than 4 hours, and use it for later use.

[0035] 1) Prepare 1.0% borax decahydrate solution as the fracturing fluid cross-linking agent, and add β-mannanase and α-galactosidase to the cross-linking agent liquid to make the final concentration reach 120U / mL and 60U / mL.

[0036] 2) Prepare 1.0% borax decahydrate solution as the fracturing fluid cross-linking agent, and add β-mannanase and α-galactosidase to the cross-linking agent liquid to make the final concentration reach 50U / mL and 25U / mL.

[0037] Take the above-mentioned cross-linking agent added with gel breaker and prepare 100 mL fracturing fluid with a cross-linking ratio (volume ratio) of 100:5, and 170s at 40°C -1 Shear for 60 minutes and record the fracturing fluid viscosity-temperature curve, such as figure 2 Shown....

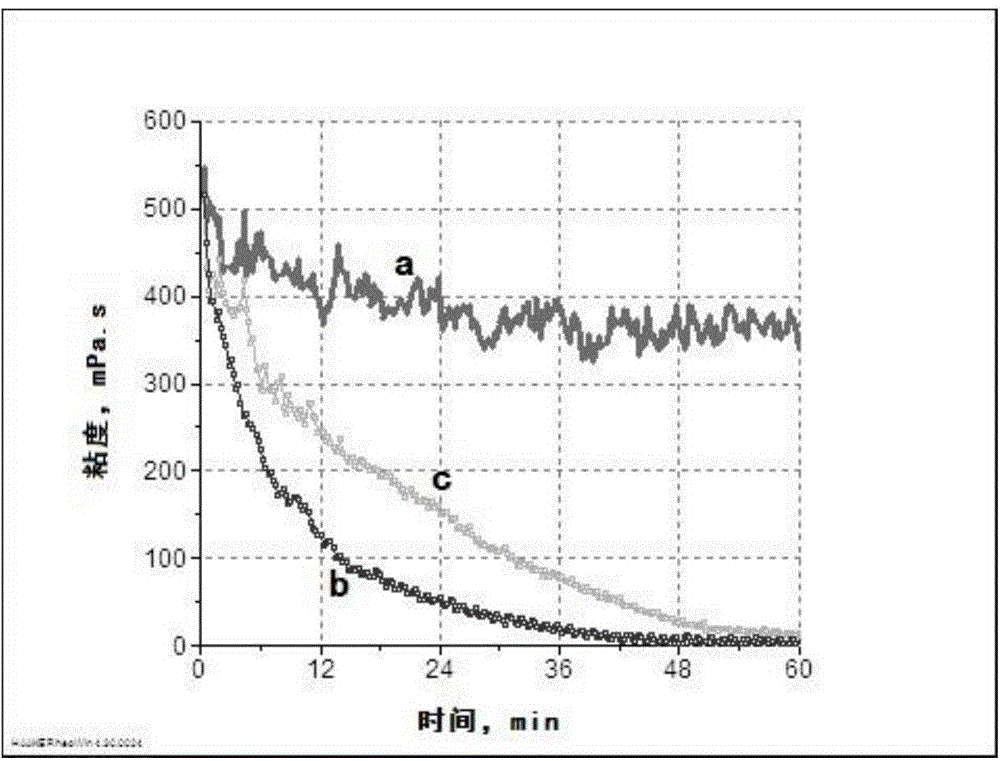

Embodiment 3

[0043] Formula of fracturing fluid base fluid: potassium chloride 2.0%, coumadin 0.4%, demulsifier 0.1%, drainage aid 0.1%. Prepare fracturing fluid base fluid according to the above formula, swell for more than 4 hours, and use it for later use.

[0044] 1) Prepare 1.0% borax decahydrate solution as the fracturing fluid cross-linking agent, and add β-mannanase and α-galactosidase to the cross-linking agent liquid to make the final concentration reach 80 U / mL and 40U / mL.

[0045] 2) Prepare 1.0% borax decahydrate solution as the fracturing fluid cross-linking agent, and add β-mannanase and α-galactosidase to the cross-linking agent liquid to make the final concentration reach 40 U / mL and 20U / mL.

[0046] Take the above-mentioned cross-linking agent added with gel breaker, and prepare 100mL fracturing fluid with a cross-linking ratio (volume ratio) of 100:5, and 170s at 60°C -1 Shear for 60 minutes and record the fracturing fluid viscosity-temperature curve, such as image 3 Shown....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com