Automatic release device for foam adsorption of gold

A technology of automatic release and foam adsorption, applied in the preparation of test samples, etc., can solve the problems that affect the accuracy and precision of analysis results, cannot be directly performed in a water bath, and block the pipette of the instrument, so as to avoid problems such as The phenomenon of clogging the suction pipe of the analytical instrument, the extrusion process is uniform and stable, and the effect of complete release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

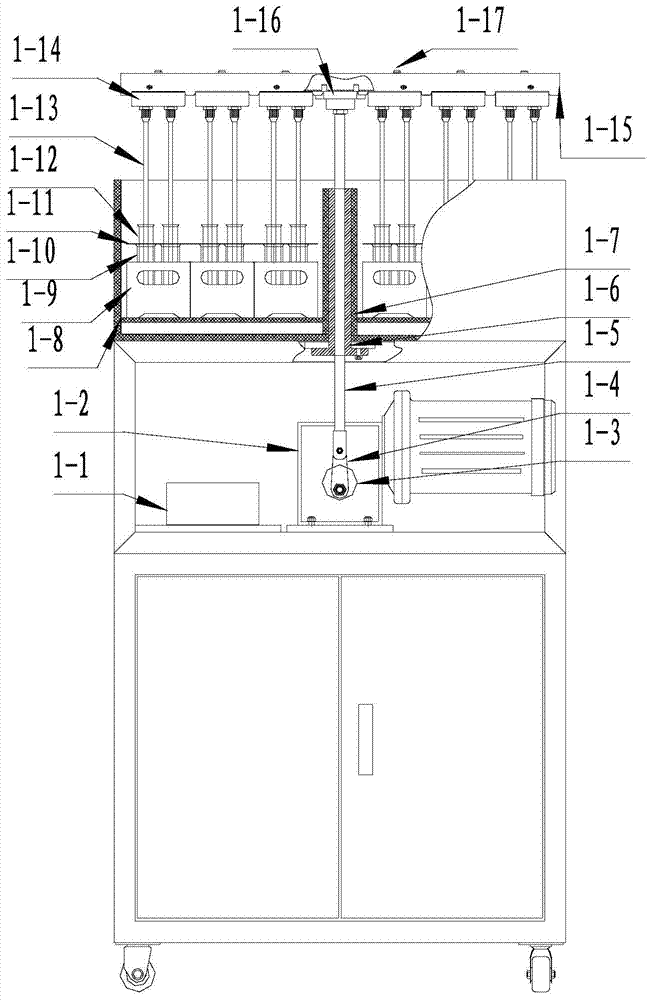

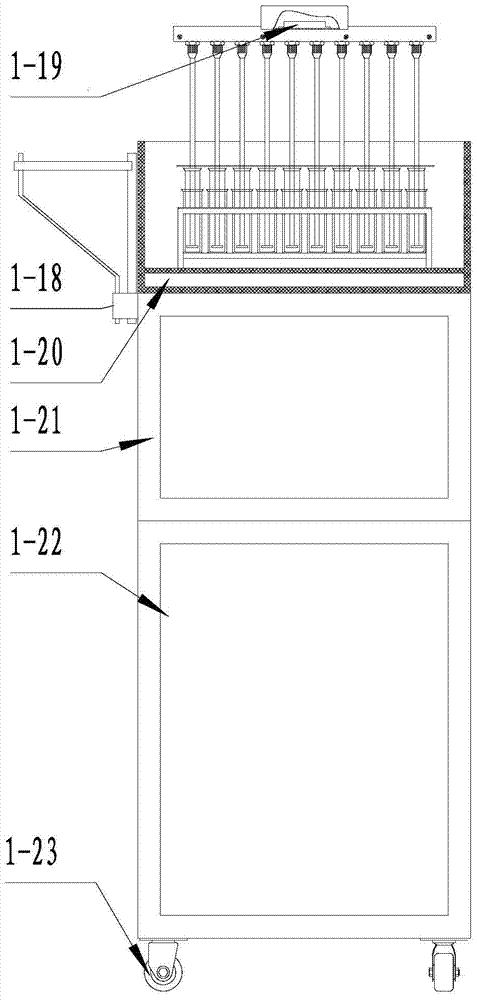

[0061] The present invention will be further described below in conjunction with the accompanying drawings.

[0062] The automatic release device of foam adsorption gold of the present invention at least comprises:

[0063] A test tube group for containing the adsorbed gold foam;

[0064] Heating the water bath for absorbing gold foam, the water bath is equipped with an electric heating tube and a temperature sensor for real-time detection of water temperature, and feeds back the water temperature to the automatic sensor;

[0065] Arranging under the water bath, extruding the extruding body that absorbs the gold foam, the extruding body is connected to the tray through an electromagnet;

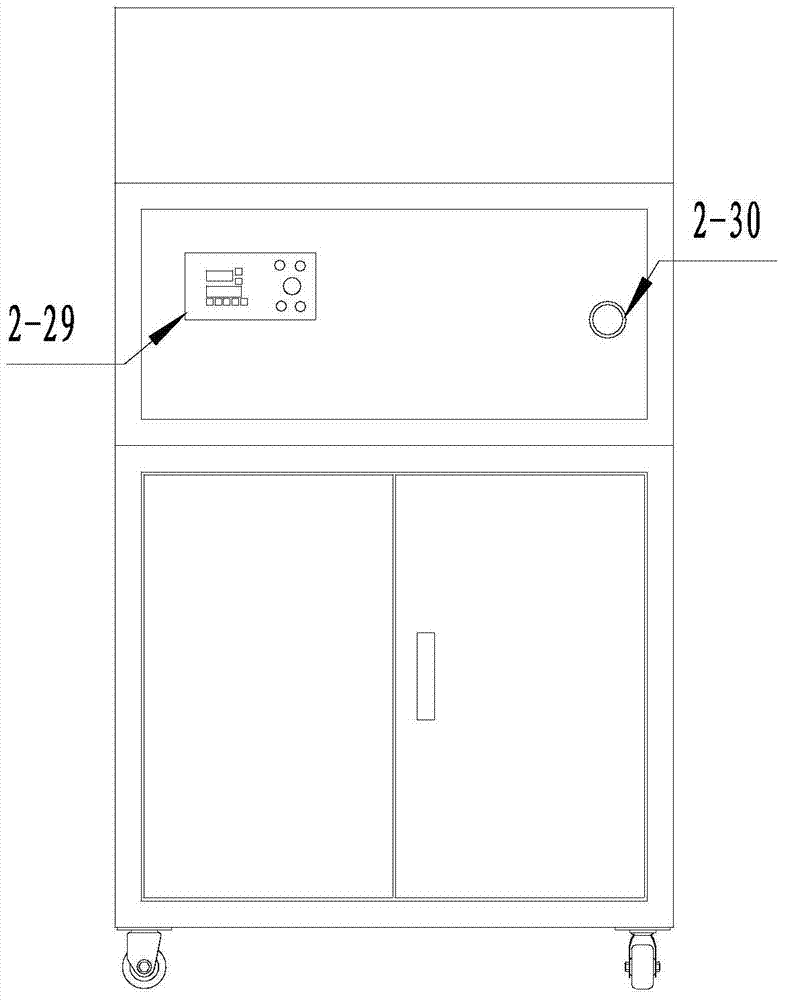

[0066] The main box includes an automatic controller; a driver that receives instructions from the automatic controller to control the working states of the electric heater, the actuator, and the suction cup; receives a start instruction from the driver, and drives the suction cup to recipro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com