Nylon 6 melt spinning method and device under external field condition

A kind of melt spinning, nylon technology, applied in spinning method and device, nylon 6 melt spinning device and fiber refinement field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

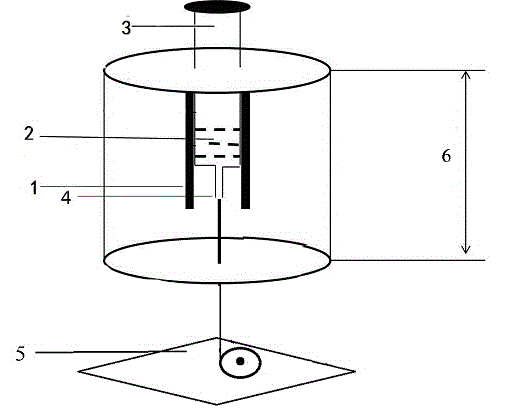

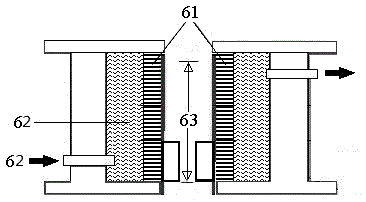

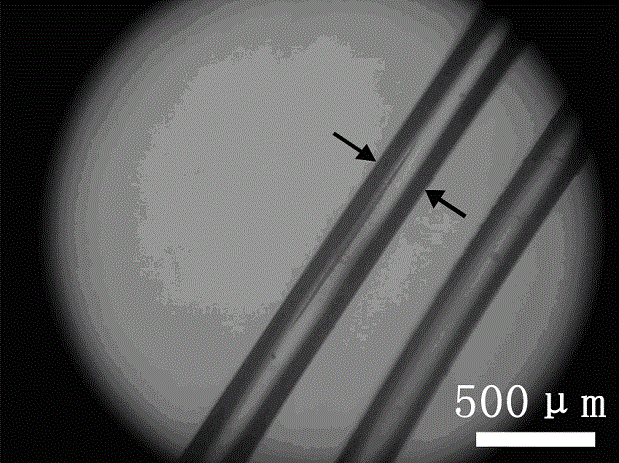

[0019] In this example, see figure 1 , figure 2 and Figure 4 , a melt spinning device of a melt spinning method under external field conditions, comprising a melting heating device 1, a material holding device 2, a feeding device 3, a spinneret 4 and a fiber collecting plate 5, and the melting heating device 1 is arranged on The periphery of the material holding device 2 heats the nylon 6 material entering the material holding device 2, and the nylon 6 material is heated to melt to form a nylon 6 melt. The spinneret 4 is installed at the bottom of the material holding device 2, and the feeding device 3 will The liquid material in the material holding device 2 is pressed down and pushed to the spinneret 4 for ejection, and the spinning formed at room temperature is received on the fiber collecting plate 5. An adjustable auxiliary pulse magnetic field device 6 is set, the auxiliary pulse magnetic field device 6 is a pulse coil 61, the temperature of the auxiliary pulse magne...

Embodiment 2

[0024] This embodiment is basically the same as Embodiment 1, especially in that:

[0025] In this example, see Figure 4 , in the melting stage, turn on the pulsed magnetic field device and set the strength and frequency, the magnetic field strength is 1.5T, and the frequency is 25 times / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com