Fluorine-free durable super-hydrophobic cotton fabric finishing agent and cotton fabric finishing method thereof

A fabric finishing agent and cotton fabric technology, which is applied in the fields of plant fiber, fiber treatment, textiles and papermaking, etc., can solve the problem of poor combination of cotton fabric finishing agent and substrate, and the method is simple and easy, and the fastness and raw materials are improved. Effects from a wide range of sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

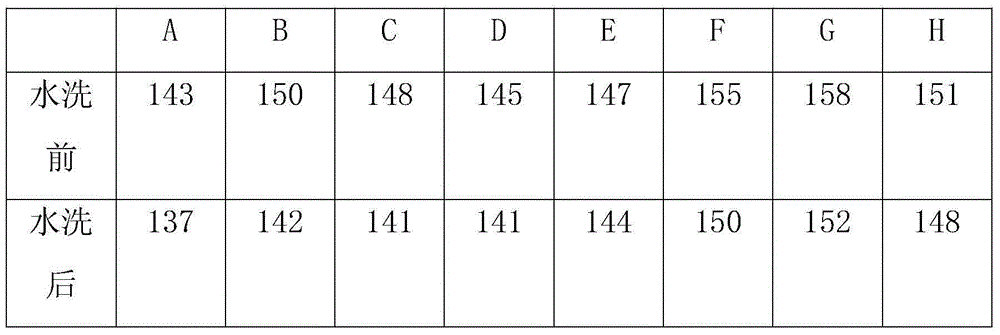

[0017] Embodiment 1: Fluorine-free durable superhydrophobic cotton fabric finishing agent A finishing cotton fabric A

[0018] Disperse 0.2 g of silicon spheres with a diameter of 150 nanometers in 100 mL of ethanol, add 10 mL of glacial acetic acid, add 5 g of dodecyltrimethoxysilane, stir at room temperature for 5 h, and obtain the modified silicon spheres after three times of centrifugation and ethanol rinsing. . Disperse 0.1 g of modified silicon spheres, 0.1 g of IPDI, and 0.01 g of dibutyltin dilaurate in 20 mL of acetone to obtain a fluorine-free durable superhydrophobic cotton fabric finishing agent A. Soak about 0.05g of cotton cloth in fluorine-free durable superhydrophobic cotton fabric finishing agent A for 1 hour, put the soaked cotton fabric in an oven for pre-baking at 80°C for 30 minutes, and bake at 120°C for 6 hours to obtain cotton fabric sample A.

Embodiment 2

[0019] Embodiment 2: Fluorine-free durable superhydrophobic cotton fabric finishing agent B finishing cotton fabric B

[0020] Disperse 0.2g of silicon spheres with a diameter of 150nm in 100mL of ethanol, add 10mL of glacial acetic acid, add 5g of hexadecyldimethoxysilane, stir at room temperature for 5h, and obtain a modified silicon sphere after three times of centrifugation and ethanol rinsing. ball. Disperse 0.1 g of modified silicon spheres, 0.1 g of HDI, and 0.01 g of dibutyltin dilaurate in 20 mL of acetone to obtain a fluorine-free durable superhydrophobic cotton fabric finishing agent B. Soak about 0.05g of cotton cloth in fluorine-free durable superhydrophobic cotton fabric finishing agent B for 1 hour, put the soaked cotton fabric in an oven for pre-baking at 80°C for 30 minutes, and bake at 120°C for 6 hours to obtain cotton fabric sample B.

Embodiment 3

[0021] Embodiment 3: Fluorine-free durable superhydrophobic cotton fabric finishing agent C finishing cotton fabric C

[0022] Disperse 0.2 g of silicon spheres with a diameter of 90 nanometers in 100 mL of ethanol, add 10 mL of glacial acetic acid, add 5 g of hexadecyldimethoxysilane, and stir at room temperature for 5 h. The obtained product is centrifuged three times and rinsed with ethanol to obtain a modified silicon ball. Disperse 0.1 g of modified silicon spheres, 0.1 g of HDI, and 0.01 g of dibutyltin dilaurate in 20 mL of ethyl acetate to obtain a fluorine-free durable superhydrophobic cotton fabric finishing agent C. Soak about 0.05g of cotton cloth in fluorine-free durable superhydrophobic cotton fabric finishing agent C for 1 hour, put the soaked cotton fabric in an oven for pre-baking at 80°C for 30 minutes, and bake at 120°C for 6 hours to obtain cotton fabric sample C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com