Method and device for utilizing magneto-thermal convection to intensify low-temperature oxygen-containing fluid heat transfer

A low-temperature fluid and heat exchange fluid technology, applied in heat transfer modification, heat exchange equipment, lighting and heating equipment, etc., can solve the problem of heat transfer method and device without low temperature oxygen-containing fluid, increase temperature difference, heat exchange area Problems such as processing technology limitations, to achieve the effect of small size, low additional energy consumption, and small flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

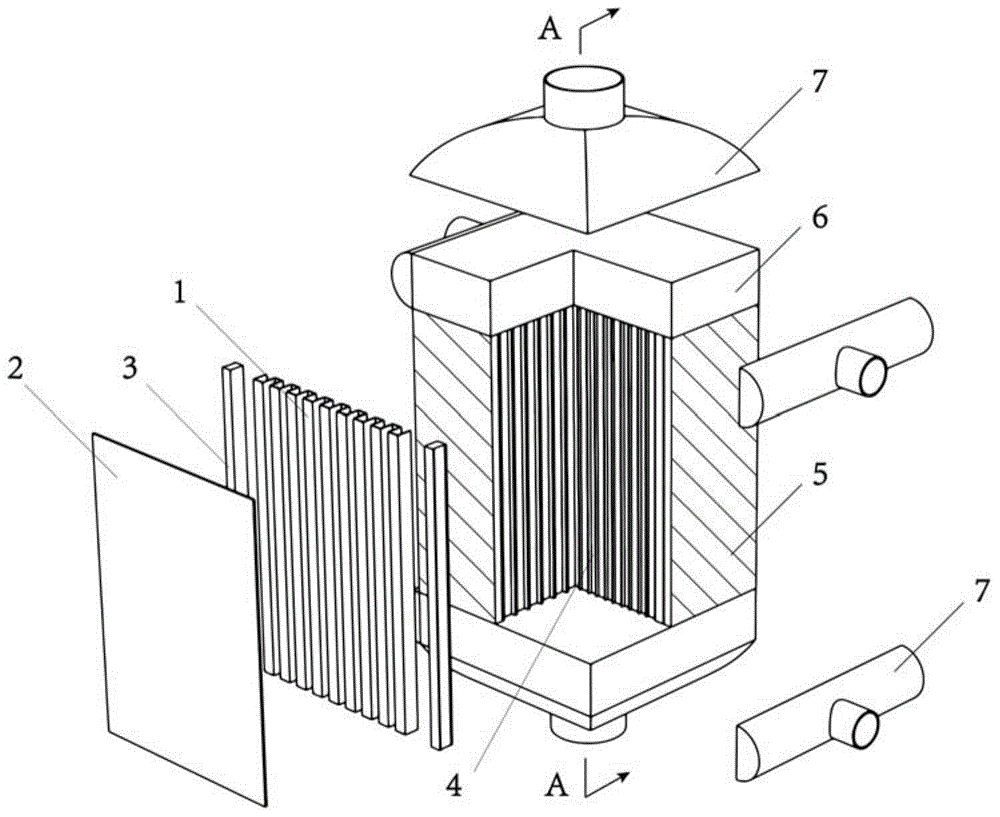

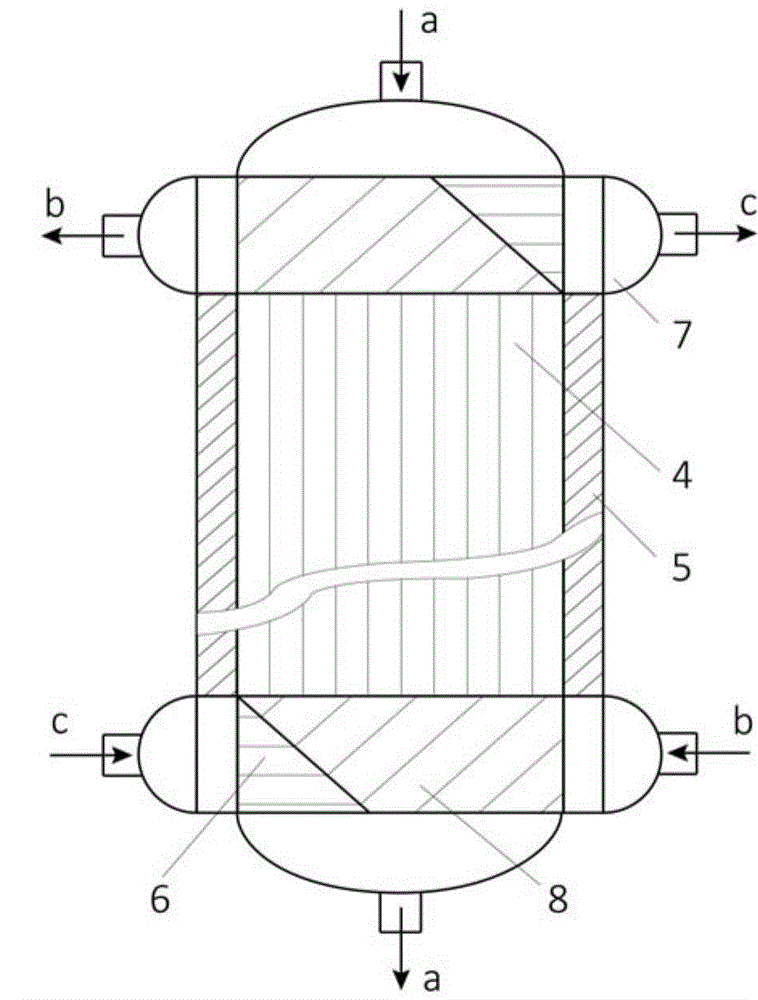

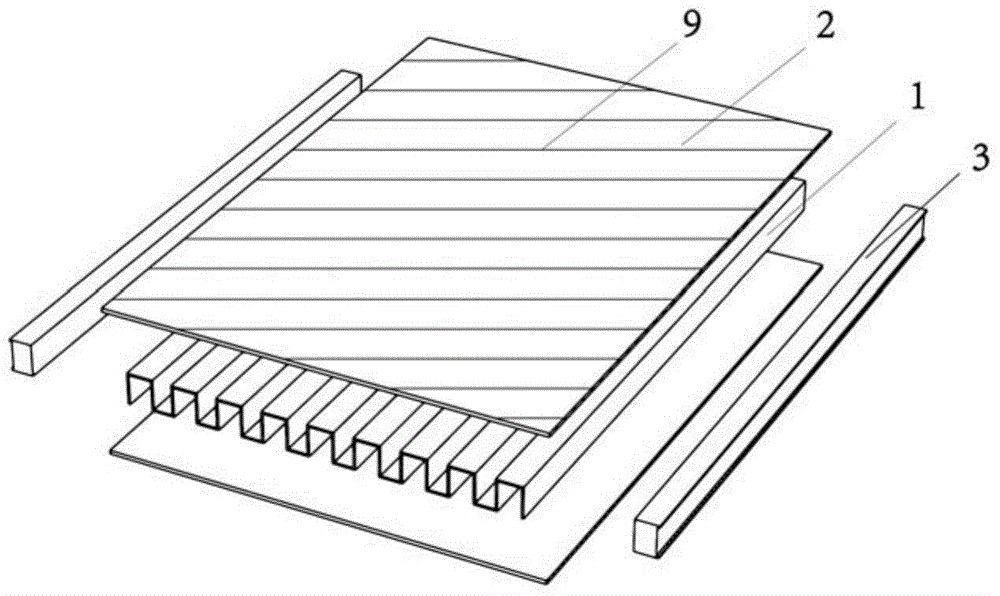

[0047] The present invention will be further described below in conjunction with accompanying drawing:

[0048] A method of using thermomagnetic convection to enhance heat transfer of low-temperature oxygen-containing fluids, including two or more streams of low-temperature oxygen-containing fluids performing non-contact heat exchange in the heat exchange channel, and then the hot fluid releases heat and the temperature decreases, and the cold fluid absorbs heat When the temperature rises, there is a gradient magnetic field that can exert force on oxygen molecules in the heat exchange area of the cold and hot fluids.

[0049] The above-mentioned non-contact heat exchange can be performed in a non-contact partitioned wall heat exchanger, and the walls participating in the heat exchange have a magnetic field, and the closer to the wall, the stronger the magnetic field intensity. Because liquid oxygen is a strong paramagnetic liquid, the oxygen-containing fluid that participate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com