A Z-source three-level PWM rectifier and its control method

A control method and a rectifier technology, which are applied to electrical components, AC power input conversion to DC power output, output power conversion devices, etc., can solve problems such as large harmonic content, achieve good waveform quality, broad prospects, and reduce AC power. Effect of Harmonic Voltage and Current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

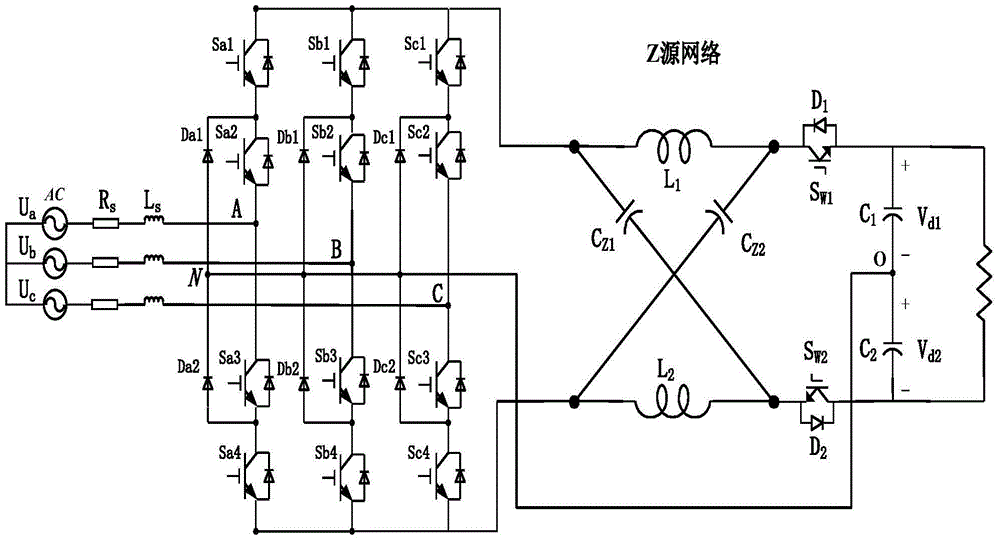

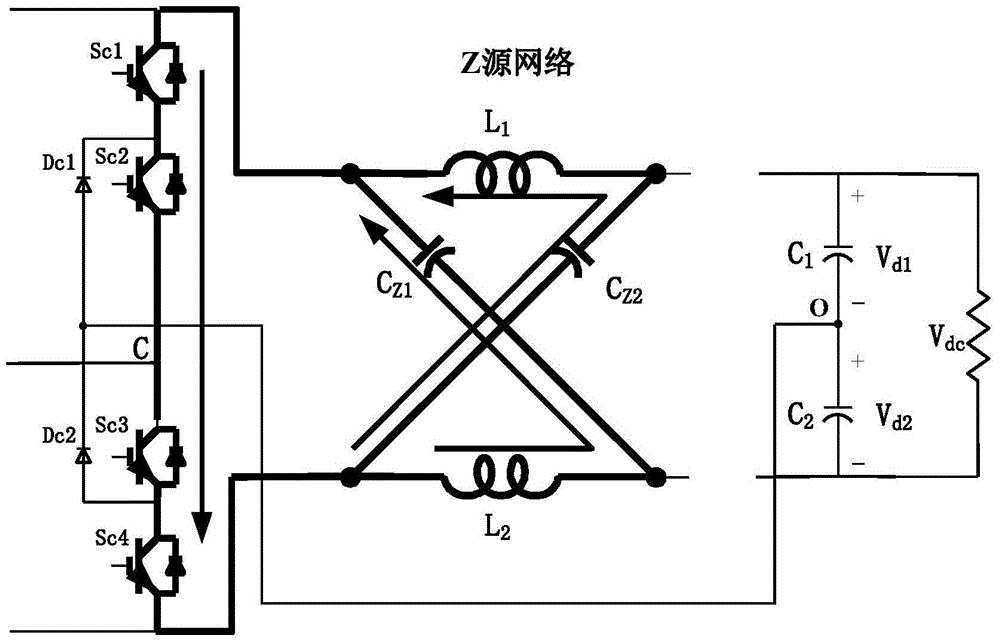

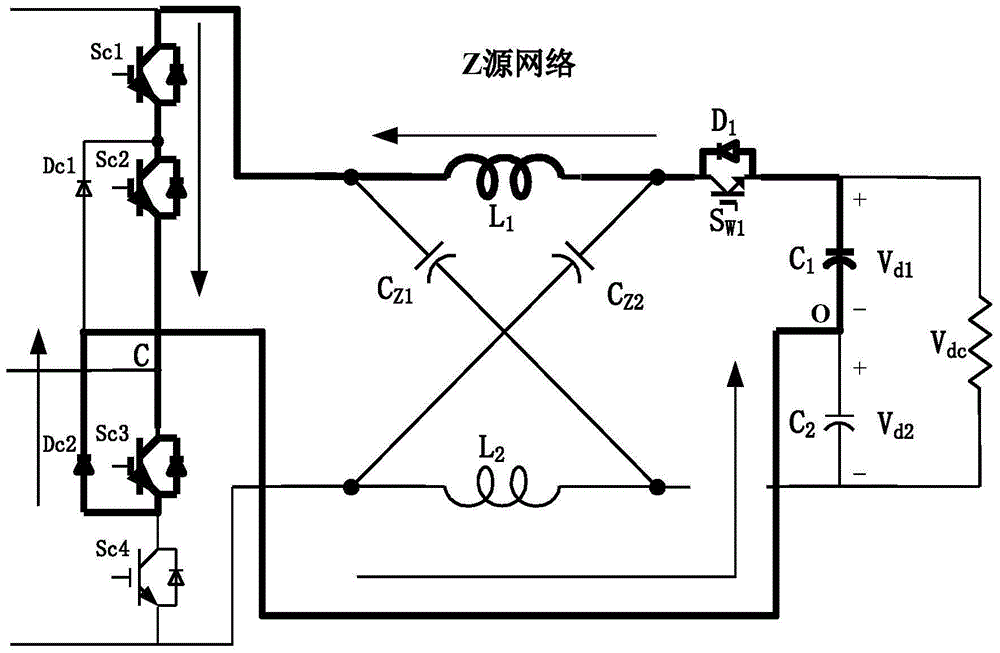

[0062] figure 1 In order to invent the structural diagram of the Z-source three-level rectifier, U a ,U b ,U c For an ideal voltage source: R S is the grid-side equivalent resistance, L S is the grid side inductance, C 1 and C 2 are DC side capacitors with equal capacitance (C 1 =C 2 ), and the corresponding voltages are V d1 and V d2 ,, o is the midpoint; the Z source network consists of two capacitors C connected into an X-like shape Z1 、C Z2 and two inductors L 1 and L 2 constitute. S W1 and S W2 are two switching tubes, respectively connected to two diodes D 1 and D 2 In anti-parallel, they are normally on in the non-shoot-through state and selectively turned off in a specific pass-through state.

[0063] The introduction of the Z source network makes it possible for each phase bridge arm of the rectifier to pass through. Therefo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com