Utilization method of yellow thick liquid obtained after preparation of bean curd through functional coagulator

A technology of coagulant and yellow syrup, which is applied in the field of food processing, can solve the problems of unsafety, human injury, and high cost, and achieve the effects of protecting nutrients, protecting the environment, and increasing added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

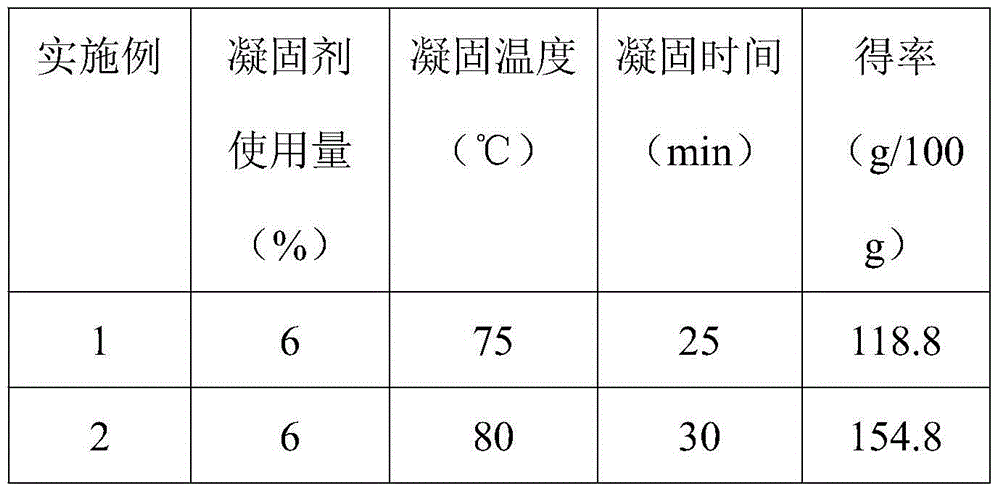

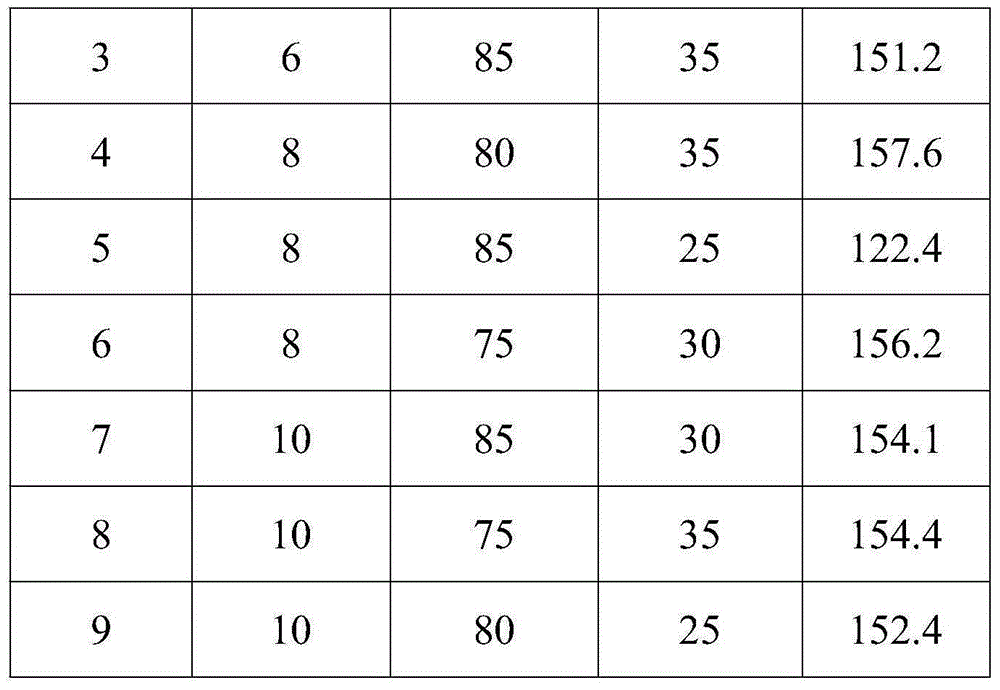

Examples

Embodiment 1

[0013] Using soybeans as raw materials, the steps of soaking, refining, boiling, filtering, cooling, ordering, squatting, and pressing are sequentially carried out to obtain tofu and yellow pulp water. The specific steps of the ordering are as follows: cool the soybean milk to 75 At ℃, adding the solution that every 100ml concentration is that the chitosan of 0.1% is dissolved in the acetic acid solution of 0.1% therein is used as coagulant, and the consumption of coagulant is 6% of soybean milk amount, and the coagulation time length is 25min.

Embodiment 2

[0015] Using soybeans as raw materials, the steps of soaking, refining, boiling, filtering, cooling, ordering, squatting, and pressing are sequentially carried out to obtain tofu and yellow pulp water. The specific steps of the ordering are as follows: cool the soybean milk to 80 When ℃, adding the solution that every 100ml concentration is that the chitosan of 0.1% is dissolved in the acetic acid solution of 0.1% wherein as coagulant, the consumption of coagulant is 6% of soybean milk amount, and the coagulation time length is 30min.

Embodiment 3

[0017] Using soybeans as raw materials, the steps of soaking, refining, boiling, filtering, cooling, pointing, squatting, and pressing are sequentially performed to obtain tofu and yellow pulp water. The specific steps of the pointing are as follows: cool the soybean milk to 85 When ℃, the concentration that every 100ml is added therein is the solution that the chitosan of 0.1% is dissolved in the acetic acid solution of 0.1% as coagulant, and the consumption of coagulant is 6% of soya-bean milk amount, and the coagulation time length is 35min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com