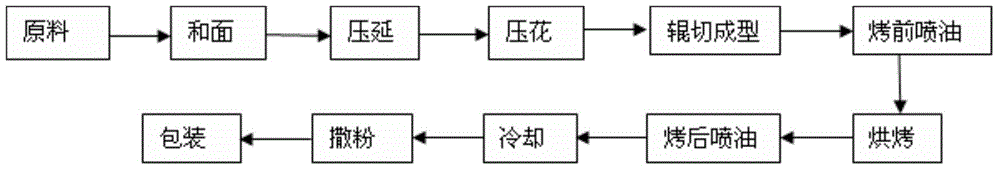

Processing process for strip potato chips

A processing technology and striped technology, applied in the field of striped potato chip food processing, can solve the problems of different vision and enjoyment of consumers, and achieve the effect of industrialization of technology, rich nutrition, and novel shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0021] Combine 46kg of potato powder, 15kg of starch, 5kg of fresh potatoes, 11kg of white sugar, and 8kg of oil

[0022] kg, 9 kg of modified starch, 3 kg of cheese powder, 3 kg of milk powder, 1.2 kg of seasoning, 0.2 kg of salt, 0.8 kg of lecithin, and 0.8 kg of food flavor, add to the horizontal dough mixer at a slow speed of 35rad / min Mix and stir for 8 minutes, add an appropriate amount of water and then turn to medium speed 55rad / min and stir for 15 minutes until agglomerated. After calendering, embossing, and roll cutting, the molding weight is controlled at 12g / 10 pieces. After spraying oil, it enters the oven for baking. The baking temperature is:

[0023] a district Second District Third District Four districts Get angry (℃) 100~140 180~220 160~190 140~180 Under fire (℃) 90~120 150~200 140~180 130~160

[0024] The baking time is 4 minutes. After the oil is sprayed out of the oven, it passes through the oil injection machine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com