Hydrogen evolution reaction catalyst nanosheet layer-graphene three-dimensional composite material and preparation method thereof

A hydrogen evolution reaction and nanosheet technology, which is applied in chemical instruments and methods, physical/chemical process catalysts, nanotechnology, etc., can solve the problems that the morphology, active site and specific surface area of transition metal dichalcogenides cannot be guaranteed. , to achieve the effect of broad industrial application prospect, convenient operation process and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Take 0.1 g of molybdenum disulfide powder and place it in 100 mL of N-methylpyrrolidone, and ultrasonically disperse for 6 hours to form dispersion A. Then 0.8 g of graphene oxide was placed in 100 mL of water and ultrasonically dispersed for 24 hours to obtain dispersion B. Take 10 mL of dispersion B and put it in a hydrothermal kettle, then add 20 mL of dispersion A respectively, then sonicate for 3 hours, and then heat the mixture to 200 o C for 12 hours. After the reaction was completed, the hydrothermal kettle was cooled, and the product was taken out, and dialyzed in water for 7 days to remove the solvent and other water-soluble impurities. Finally, the columnar product was frozen in liquid nitrogen, and then freeze-dried with a freeze dryer for 5 days to obtain an airgel.

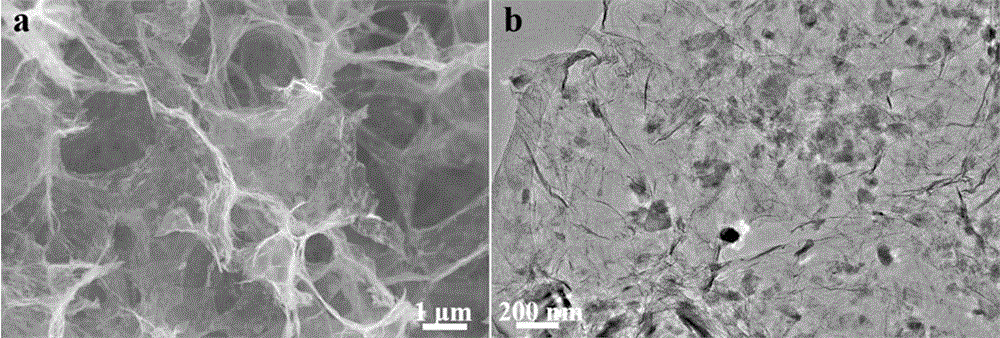

[0021] From figure 1 It can be seen that the prepared molybdenum disulfide nanosheet-graphene composite has a very obvious pore structure, indicating that its specific surface area is larg...

Embodiment 2

[0023] Take 0.3 g of molybdenum disulfide powder and place it in 50 mL of N,N-diformamide, and ultrasonically disperse for 24 hours to form dispersion A. Then 0.08 g of graphene oxide was placed in 10 mL of water and ultrasonically dispersed for 3 hours to obtain dispersion B. Take 10 mL of dispersion B and put it in a hydrothermal kettle, then add 1 mL of dispersion A respectively, then sonicate for 0.5 hours, and then heat the mixture to 140 o C for 18 hours. After the reaction was completed, the hydrothermal kettle was cooled, and the product was taken out, and dialyzed in water for 5 days to remove the solvent and other water-soluble impurities. Finally, the columnar product was frozen in liquid nitrogen, and then freeze-dried with a freeze dryer for 3 days to obtain an airgel.

Embodiment 3

[0025] Take 0.1 g of tungsten disulfide powder and place it in 30 mL of formamide, and ultrasonically disperse for 18 hours to form dispersion A. Then 0.5 g of graphene oxide was placed in 50 mL of water and ultrasonically dispersed for 12 hours to obtain dispersion B. Take 10 mL of dispersion B and put it in a hydrothermal kettle, then add 1 mL of dispersion A respectively, then sonicate for 0.5 hours, and then heat the mixture to 140 o C for 24 hours. After the reaction was completed, the hydrothermal kettle was cooled, and the product was taken out, and dialyzed in water for 5 days to remove the solvent and other water-soluble impurities. Finally, the columnar product was frozen in liquid nitrogen, and then freeze-dried with a freeze dryer for 3 days to obtain an airgel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com